Polyurethane Foaming Machine | PU Foaming Machine

Provide You with Polyurethane Foaming Machine Solutions

Foaming Machines for Polyurethane offer solutions for high accuracy and reliability in many applications. With 25 years of experience, we provide customised systems that meet your requirements. We have high and low-pressure foaming machines.

Trustworthy Manufacturer of Polyurethane Equipment in China

Zhejiang Henghui Machinery Co., Ltd. has more than 25 years of experience and is an acknowledged pioneer and leader in the production of polyurethane machinery.

Our two, three, and multi-component machineries are built with the purpose of strength and sustained production.

We are ISO 9001:2000 certified and produce over 100 machines per year, with more than 2,500 of our machines currently operating in the field.

From our cyclopentane foaming machines to our sole foaming and edge-bonding specialty machinery, we provide our clients with high-end value and custom equipment matched with turnkey production for seamless production automation. We serve clients globally.

Contact Us Now

Enter your inquiry details, We will reply you in 6 hours.

Advanced Polyurethane Foaming Machine for Diverse Applications

Any business that requires accuracy, efficiency, and flexibility needs a polyurethane foaming machine. These machines are designed to handle a variety of applications, from high-pressure systems ideal for more complex, advanced manufacturing to low-pressure systems that are more economical.

What is Polyurethane Foaming Machine?

A Polyurethane foaming machine is a type of equipment used to mix and dispense polyurethane foam. It is used in a variety of industries, including construction, automotive, and furniture. Unlike other mixing methods, these machines mix at a low, controlled temperature to create foams with specific properties. This is a unique and handy functionality for different fields in manufacturing.

A Polyurethane foaming machine is designed to mix, meter, and dispense the materials used to make foam in a fast, efficient, and sustainable way. The system in the machine controls and eliminates the potential for aberrant foam formation, ensuring uniformly foamed material is dispensed and that waste is kept to a minimum. It is even more beneficial for the production of foams and offers high performance and durability.

The Significance of Polyurethane Foaming Machines in Manufacturing

In manufacturing, polyurethane foaming machines assist in mixing, pumping, and shaping polyurethane into specific forms; they are essential to production. The machines mix the liquid precursors at a precise ratio and create a consistent foamed product, which is lightweight, solid, and strong, and the foamed products (plastics) are beneficial across numerous industries. The machines are indispensable.

One application of the machines is insulating foam. The machines are designed to meet the necessary specifications for the foaming agent. There is a built-in temperature control system that ensures the desired foamed quality and density are achieved. Uniform, consistent foam is essential in a roof.

Understanding the Difference Between High-Pressure and Low-Pressure Foaming Machines

There are many advantages to high-pressure foam machines over low-pressure ones. First of all, high-pressure foaming machines tend to mix the foam much better, improving the overall quality of the foam produced and reducing foam waste. Also, high-pressure foam machines are great for large-scale production. They can be used in a multitude of industries, as they serve different production and application needs in which the foams produced must be controlled with exact control.

The differences in design and operating principles between high-pressure and low-pressure foaming machines explain the distinction between the two. In low-pressure foaming machines, the chemical components are mixed mechanically, whereas in high-pressure foaming machines, sophisticated metering pumps are paired with high-speed impingement mixing for improved mixing. In addition, high-pressure machines offer better temperature and material flow control, resulting in greater precision in the production of high-quality foam products.

Some Advantages of Polyurethane Foaming Machines

Polyurethane foaming machines are helpful for various manufacturing processes. Here are some of the advantages they bring.

- Better Mixing and Dispensing. Advanced metering mixing systems ensure the correct chemical ratio is used, minimising material waste.

- Increased Production Efficiency. The design is continuous for even greater overall efficiency.

- Flexibility for Production. They are capable of producing a variety of foams, from insulation to automotive applications and beyond.

- Advanced Temperature Control. These machines are equipped with heating systems to maintain consistent foam temperatures.

- Better Quality Foam. The foam is uniformly dense and has a consistent structure. The foam is also defect-free, which enhances the performance of the end product.

- Waste is Reduced. The machines reduce the purchase of raw materials and also avoid the use of excess cleaning agents.

- Flexibility for Design. They have custom structures to suit the needs of specific production, which enhance system and material compatibility.

- Designed to be Environmentally Friendly. The machines are designed to be environmentally friendly by optimising the materials and energy used.

With these advantages, foaming machines for polyurethane have been used across the construction, automotive, and furniture manufacturing industries.

Types of Polyurethane Foaming Machines

While polyurethane foaming machines share many standard features and principles, there are different types designed for specific applications and requirements. Two main categories of polyurethane foaming machines are widely used in various industries:

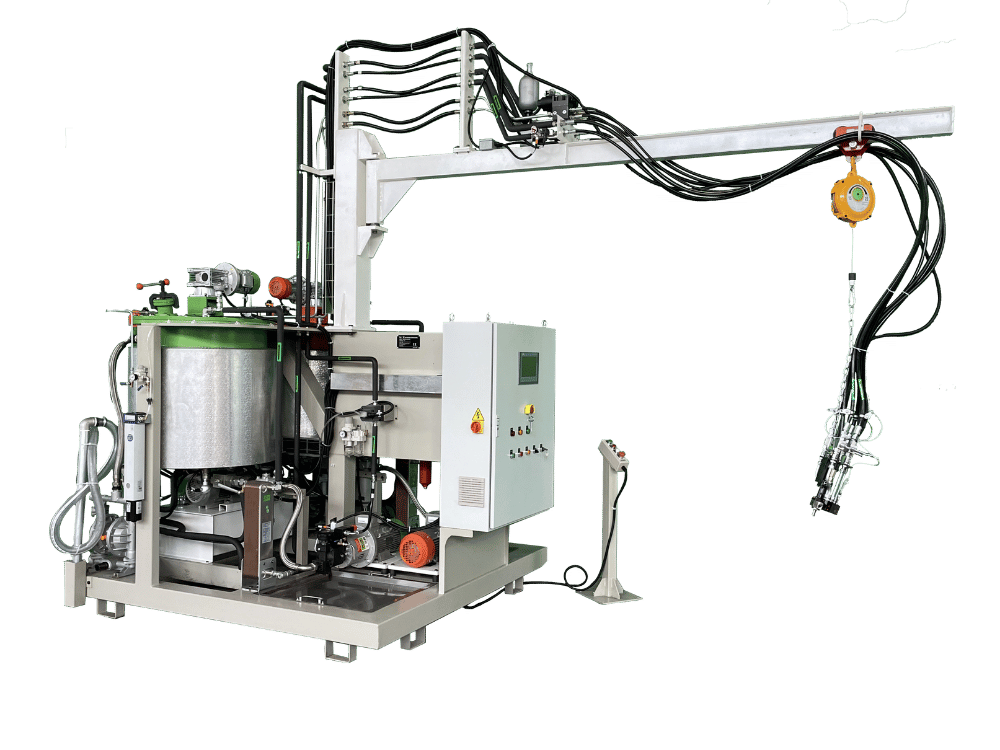

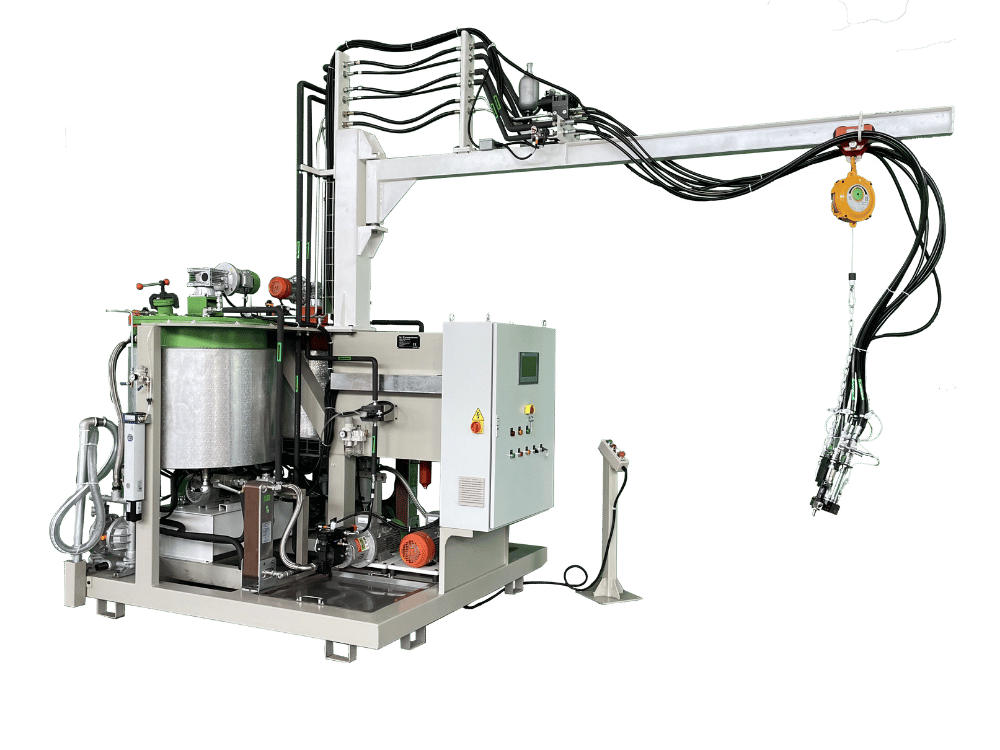

High-Pressure Foaming Machines

High-pressure foaming machines are designed for applications requiring precise mixing and minimal material waste. These machines use advanced metering pumps and high-speed impingement mixing to ensure superior foam quality.

- Two-Component High-Pressure Foaming Machine: Ideal for applications requiring accurate mixing of two chemical components.

- Three-Component High-Pressure Foaming Machine: Offers enhanced flexibility for more complex formulations and production needs.

- Cyclopentane High-Pressure Foaming Machine: An eco-friendly option, specifically designed for sustainable production using cyclopentane as a blowing agent.

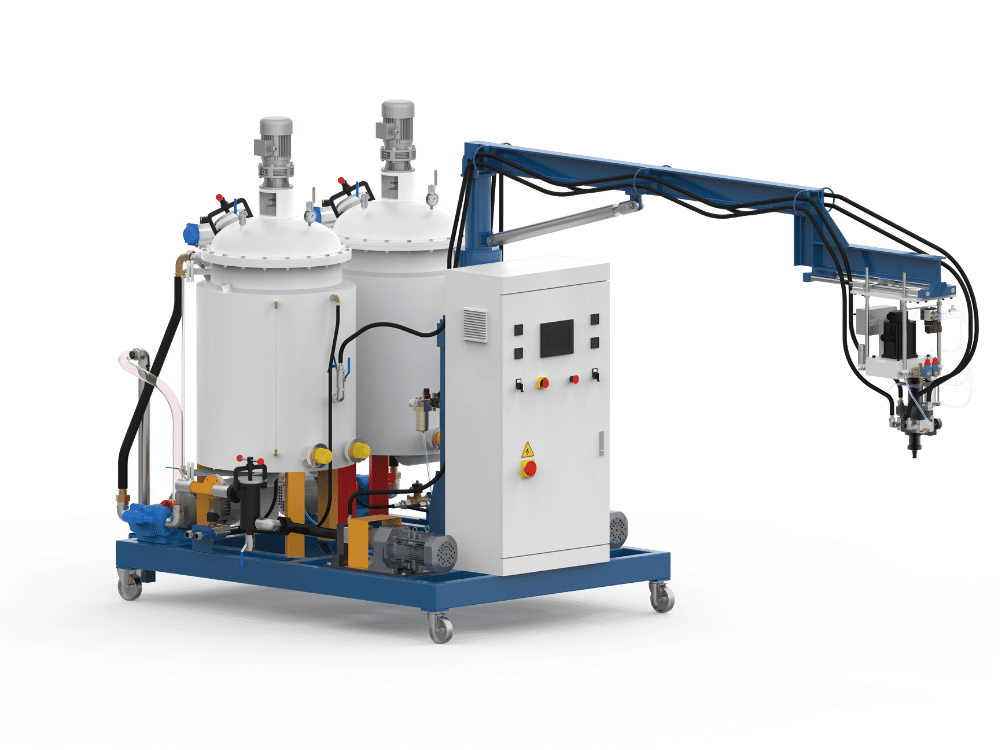

Low-Pressure Foaming Machines

Low-pressure foaming machines are cost-effective and suitable for smaller-scale operations or specialized applications. These machines rely on mechanical mixing to combine the chemical components.

- Two-Component Low-Pressure Foaming Machine: Reliable and efficient for basic production needs.

- Polyurethane Sole Foaming Machine: Specially designed for footwear production, ensuring consistent foam density and quality.

- Polyurethane Spraying Machine: Ideal for coating and insulation applications, providing precise and uniform foam application.

The choice between high-pressure and low-pressure foaming machines depends on factors such as production scale, material properties, and specific application requirements. Manufacturers often collaborate with equipment suppliers to select the most suitable type and configuration for their needs, ensuring optimal performance and product quality.

Applications of Polyurethane Foaming Machines

- Construction Industry: Insulation panels, roofing materials, and sealants.

- Automotive Industry: Seat cushions, dashboards, and soundproofing components.

- Furniture Manufacturing: Mattresses, cushions, and upholstery.

- Appliance Industry: Refrigeration insulation and gaskets.

- Specialized Applications: Tyre foaming, edge bonding, and block foam production.