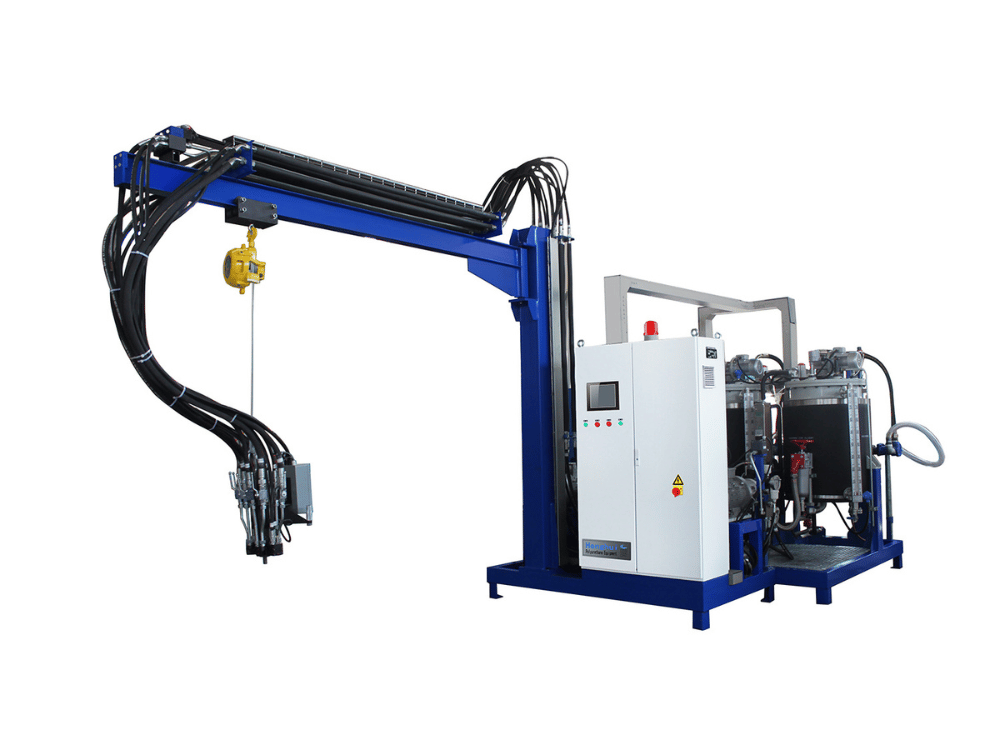

Three-Compoent Polyuretahne High-Pressure Foaming Machine

Provide You with Polyurethane High-Pressure Foaming Machine Solutions

Our JHG30 Series Three-Component Polyurethane High-Pressure Foaming Machine delivers precision and efficiency, achieving excellent mixing results across diverse applications. With over 20 years of expertise, we provide tailored solutions to meet your production needs.

Trustworthy China Polyurethane Machine Manufacturer

Founded in 1999, Zhejiang Henghui Machinery Co., Ltd. is a trusted leader in the manufacturing of polyurethane equipment. The JHG30 Series adopts a hydraulic-driven self-cleaning mixing head, ensuring superior mixing results, reduced raw material waste, and an eco-friendly production process. Certified to ISO9001:2000, we produce over 100 sets of polyurethane equipment annually, with more than 2,500 sets in operation worldwide. We offer fully customizable solutions and end-to-end services, from design to support, ensuring seamless production for clients across the globe.

Contact Us Now

Enter your inquiry details, We will reply you in 6 hours.

JHG30 Series: Advanced Three-Component Polyurethane High-Pressure Foaming Machine

The JHG30 Series is a reliable, fully equipped, and customizable three-component polyurethane high-pressure foaming machine. Designed for medium to high production volumes, it delivers exceptional mixing performance, cost efficiency, and environmental sustainability.

Parameters

| TYPE | OUTPUT (g/s) |

|---|---|

| A40/20 | 50 - 410 |

| A100/40 | 110 -820 |

Outlet quantity form(g/s)

How It Works:

The JHG30 operates by storing raw chemicals (poly and iso) in drums or IBC containers. These materials are absorbed by a filling pump and transferred to the machine’s individual storage tanks. Axial piston metering pumps then drive the raw materials into the mixing chamber of the mixing head.

As the materials flow through larger-diameter hoses into smaller cones, their speed and pressure increase, resulting in excellent mixing performance. This process exemplifies the efficiency of a high-pressure foaming machine.

Key Advantages Over Low-Pressure Foaming Machines:

Unlike low-pressure foaming machines that use motor-driven turbines for mixing, the JHG30 Series employs a hydraulic-driven, self-cleaning mixing head. This innovative design offers several benefits:

Reduced Material Waste

The self-cleaning mixing head minimizes raw material loss.

No Cleaning Agents Required

Eliminates the need for cleaning agents during production, reducing running costs and environmental impact.

Superior Mixing Results

Ensures consistent and high-quality mixing performance.

Characteristics:

- 250-liter tanks

- Capacitive levelmeter

- Axial-piston dosing pumps with magnet coupling

- HPE Self-cleaning L-type (or straight-type) mixing head

- Volumetric flowmeter

- Touchscreen HMI

Suitable Applications & Industries

- Automotive: Seating, headrests, armrests, dashboards, and sound insulation.

- Construction & Insulation: Rigid foam panels, spray foam for insulation, and sandwich panels.

- Appliances: Insulation for water heaters, refrigerators, and freezers.

- Furniture & Bedding: Mattresses, sofa cushions, and ergonomic office chairs.

- Technical Parts: Custom gaskets, packaging, and industrial components.

Why Choose the JHG30 Series?

The JHG30 Series stands out for its advanced features, reliability, and adaptability. With three chemical tanks (typically two poly and one iso), it can handle products with varying densities and chemical systems, all within a single unit. This makes it the ideal choice for industries that require efficient, high-quality polyurethane foaming solutions.