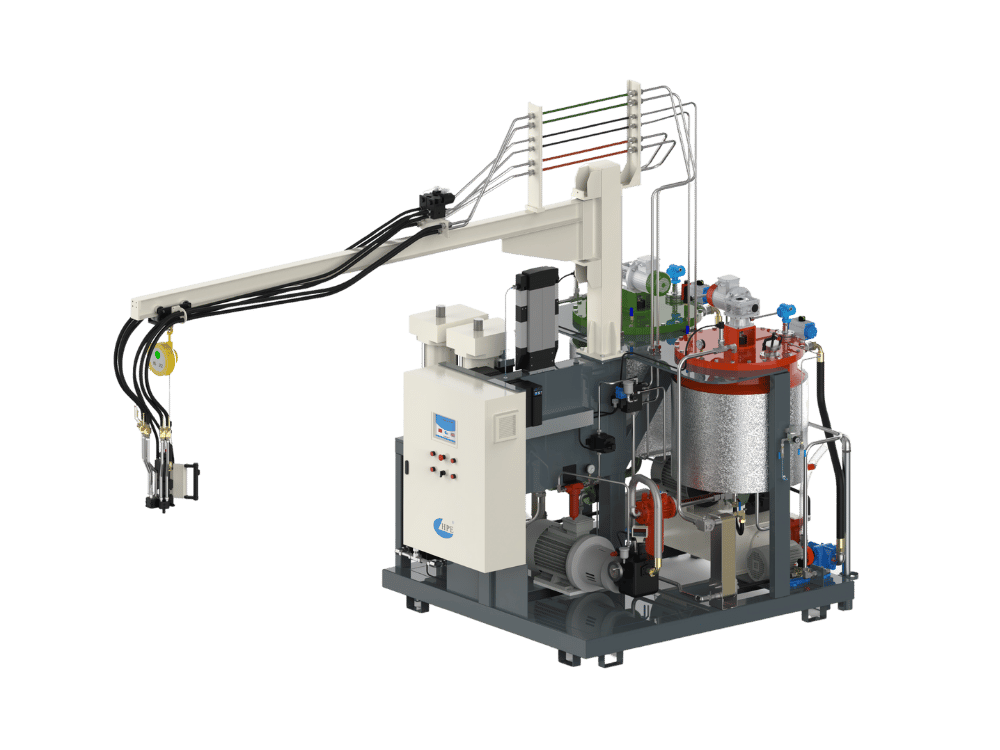

Piston Meering High Pressure Foaming Machine

Provide You with Advanced Polyurethane Foaming Solutions

The PUR Hybrid Series Piston Metering High-Pressure Foaming Machine is designed to meet the demands of modern polyurethane applications. Incorporating fillers into raw materials enhances foam properties such as sound insulation and flame retardancy. With over 20 years of expertise, we deliver tailored solutions to ensure superior performance and durability in your production process.

Trustworthy China Polyurethane Equipment Manufacturer

Founded in 1999, Zhejiang Henghui Machinery Co., Ltd. is a trusted leader in the manufacturing of polyurethane equipment. The PUR Hybrid Series features servo-hydraulically driven reciprocating piston pumps, ensuring precise metering of polyol and isocyanate, even with corrosive fillers such as barium sulfate, calcium carbonate, fiberglass, and wollastonite. It is also suitable for high-viscosity or air-rich polyurethane systems (up to 60% air content).

Certified to ISO9001:2000, we produce over 100 sets of polyurethane equipment annually, with more than 2,500 sets in operation worldwide. We provide customized solutions and end-to-end services, from design to support, ensuring seamless production for clients across the globe.

Contact Us Now

Enter your inquiry details, We will reply you in 6 hours.

PUR Hybrid Series: Advanced Piston Metering Foaming Machine

The PUR Hybrid Series Piston Metering High-Pressure Foaming Machine is designed to meet the demands of modern polyurethane applications. Incorporating fillers into raw materials enhances foam properties such as sound insulation and flame retardancy. Unlike traditional axial-piston pumps, the PUR Hybrid Series uses a reciprocating piston pump, making it ideal for handling corrosive fillers, high-viscosity materials, and air-rich polyurethane systems.

How It Works

The PUR Hybrid Series features servo hydraulically driven pistons which allow the precise metering of polyol and isocyanate during processing to yield consistent quality.

A primary function of the device is working with corrosive fillers. Examples are barium sulfate and calcium carbonate, fiberglass and wollastonite, and so, which enhance the versatility of the machine polymer.

The device is made to handle high viscosity and air content of polyurethane components up to 60 % to allow seamless operation and consistent quality of foam.

The reciprocating piston pump design is highly worn resistant, making it ideal to use in harsh working conditions.

This complex design is what makes the PUR Hybrid Series strong and reliable for contemporary applications in polyurethane foaming.

Key Advantages Over Traditional Axial Piston Pump Machines

Unlike low-pressure foaming machines that rely on motor-driven turbines for mixing, the N Series employs advanced high-pressure technology with a hydraulic-driven mixing system. This innovative design offers several significant advantages:

Enhanced Wear Resistance

Designed to withstand the abrasive nature of fillers, ensuring long-term durability.

Versatility

Handles a wide range of polyurethane systems, including those with high viscosity or air content.

Improved Foam Properties

Enhances sound insulation, flame retardancy, and overall foam quality.

Efficient Metering

Hydraulically driven servo pistons ensure precise, consistent material flow.

Reduced Maintenance

The robust design minimizes downtime and maintenance costs.

Customizable Applications

Suitable for industries requiring advanced polyurethane solutions, from technical parts to consumer goods.

Characteristics:

- Reciprocating Piston pump

- Capacitive levelmeter

- Wear resistance mixing head

- Precise metering of components through piston stroke

- Touchscreen HMI

- Suitable for fillers (barium sulfate, calcium carbonate, fiberglass, wollastonite., etc)

Suitable Applications & Industries

- Seating, headrests, and armrests

- Dashboards and interior panels

- Sound insulation and vibration dampening

- Rigid foam panels for walls and roofs

- Spray foam for thermal and acoustic insulation

- Sandwich panels for structural applications

- Mattresses, pillows, and cushions

- Sports equipment, such as foam grips and padding

- Insulated water bottles and coolers

Why Choose the PUR Hybrid Series?

The PUR Hybrid Series stands out for its innovative design, reliability, and adaptability. It is engineered to deliver exceptional results in polyurethane foaming applications, making it the ideal choice for industries requiring advanced solutions for challenging materials.