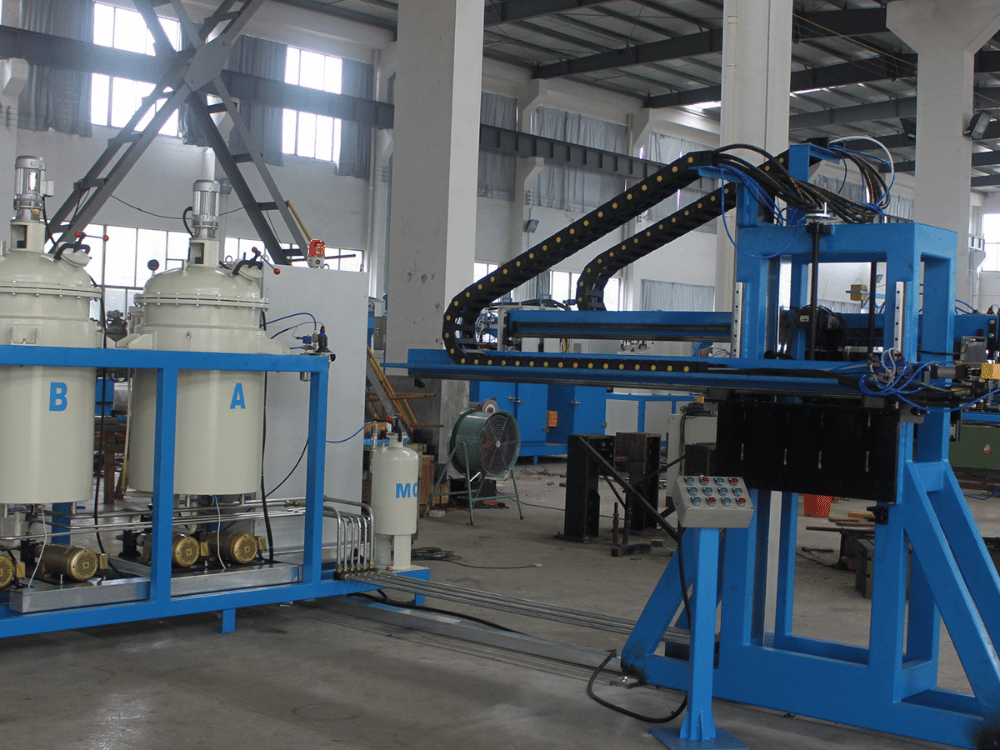

Polyurethane Sole Foaming Machine

Provide You with Polyurethane Spray Machine Solutions

Our LS Series Polyurethane Spray Machine delivers precision and efficiency, ensuring superior bonding performance in composite panel production. With over 20 years of expertise, we provide tailored solutions to meet the demands of modern manufacturing lines.

Trustworthy China Polyurethane Equipment Manufacturer

Founded in 1999, Zhejiang Henghui Machinery Co., Ltd. is a trusted leader in the manufacturing of polyurethane equipment. The LS Series features a servo-controlled swing-movement system, enabling continuous, precise adhesive spraying on double-belt rockwool composite panel production lines.

Certified to ISO9001:2000, we produce over 100 sets of polyurethane equipment annually, with more than 2,500 sets in operation worldwide. We provide end-to-end services, from design to support, ensuring seamless production for clients across the globe.

Contact Us Now

Enter your inquiry details, We will reply you in 6 hours.

LS Series: Precision Polyurethane Spray Machine for Composite Panels

The LS Series Polyurethane Spray Machine is a reliable and efficient solution for applying adhesive or glue onto substrate surfaces during the production of polyurethane composite panels. Designed for precision and superior bonding performance, it is ideal for double-belt rockwool composite panel production lines.

How It Works:

The LS Series uses advanced technology to deliver consistent, high-quality results.

First, the machine sprays adhesive or glue onto the substrate surface, ensuring superior bonding performance. This precise application ensures strong adhesion, critical to the durability and reliability of composite panels.

A servo-controlled swing-movement system plays a key role in the process. It enables continuous and precise spraying, ensuring uniform adhesive distribution across the panel surface. This advanced feature minimizes material waste and enhances production efficiency.

Designed explicitly for double-belt rockwool composite panel production lines, the LS Series integrates seamlessly into modern manufacturing processes. Its optimized design ensures uninterrupted operation, making it an ideal choice for high-efficiency production environments.

Key Features and Benefits of PU Spraying Machine

Unlike traditional spray machines, the LS Series employs a servo-controlled swing arm system, ensuring continuous, precise adhesive application for superior bonding performance. This design offers several benefits:

Precision Spraying

The servo-controlled swing moving system ensures accurate and consistent adhesive application.

Continuous Operation

Designed for uninterrupted spraying, improving production efficiency and reducing downtime.

Superior Bonding Performance

Achieves strong and reliable adhesion for polyurethane composite panels.

Versatile Applications

Ideal for double belt rockwool composite panel production and other adhesive-based manufacturing processes.

User-Friendly Design

Easy to operate and maintain, ensuring smooth and efficient production.

Energy Efficiency

Optimized spraying technology reduces adhesive waste and energy consumption, lowering operational costs while maintaining high performance.

Characteristics:

- Servo-controlled swing moving system for precise and continuous spraying

- High-precision metering system for accurate adhesive application

- Two spray mixing heads for enhanced efficiency and flexibility

- Adjustable output flow for in-line customization during production

- Modular design for easy integration and maintenance

- Optimized for double-belt rockwool composite panel production lines

- Continuous operation to improve production efficiency and reduce downtime

- User-friendly design for smooth operation and maintenance

- Energy-efficient technology to minimize adhesive waste and reduce operational costs

Suitable Applications & Industries

- Construction & Insulation: Adhesive spraying for double belt rockwool composite panels and other thermal or acoustic insulation panels

- Automotive: Bonding applications for composite materials in vehicle interiors and exteriors

- Appliances: Adhesive application for composite panels in refrigerators, freezers, and water heaters

- Furniture & Bedding: Bonding layers in ergonomic furniture, mattresses, and cushions

- Industrial Manufacturing: Adhesive-based production processes requiring precision and efficiency

Why Choose the LS Series PU Spraying Machine

The LS Series stands out for its precision, efficiency, and adaptability. It is engineered to deliver exceptional results in polyurethane spray applications, making it the ideal choice for manufacturers seeking reliable and scalable solutions. Contact us today to learn how the LS Series can enhance your production efficiency!