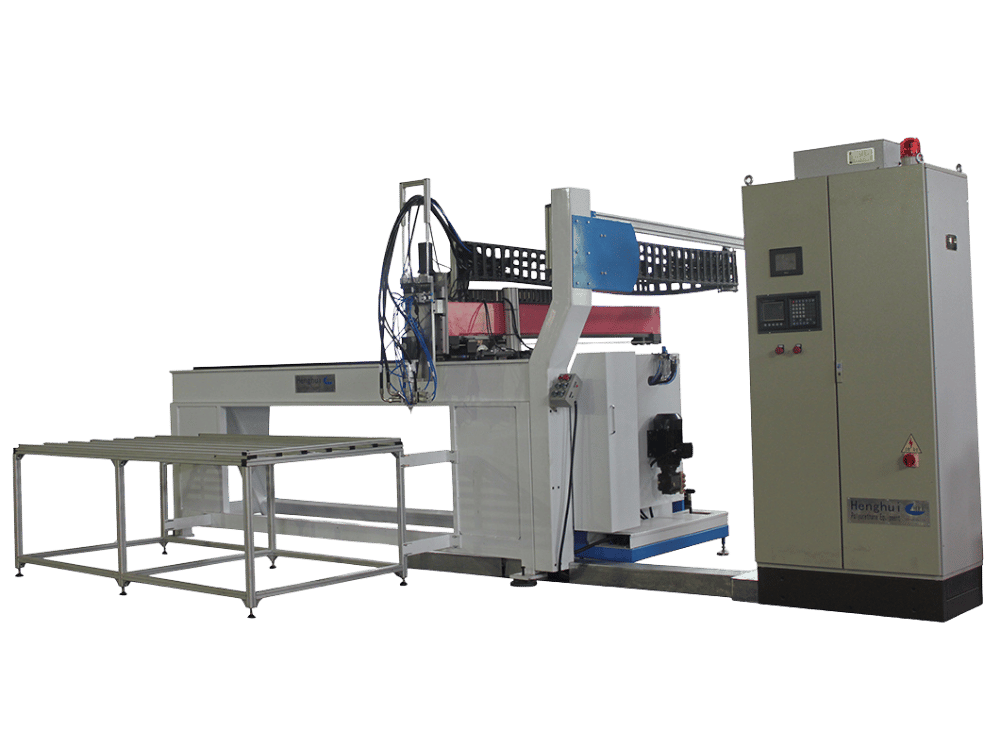

Polyurethane Foam Strip Gasket Dosingmachine

Provide You with Polyurethane Equipment Solutions

Our JHT20/30 series Polyurethane Foam Strip Gasket Dosing Machine delivers precision and efficiency, producing high-quality foam for polyurethane seals and end caps. With over 20 years of expertise, we provide tailored solutions for your polyurethane production needs.

Trustworthy China Polyurethane Equipment Manufacturer

Founded in 1999, Zhejiang Henghui Machinery Co., Ltd. is a trusted leader in the manufacturing of polyurethane equipment. Our JHT20/30 series integrates CNC linear robots and fixed workbenches, ensuring precision and reliability. Certified to ISO 9001:2000, we produce over 100 types of polyurethane equipment annually, with more than 2,500 sets in operation worldwide. We offer customized solutions and comprehensive services, ensuring seamless production for clients worldwide.

Contact Us Now

Enter your inquiry details, We will reply you in 6 hours.

JHT20/30 Series

Advanced Polyurethane Foam Strip Gasket Dosing Machine

The JHT20/30 Series is a cutting-edge polyurethane foam strip gasket dosing machine designed for precision and efficiency. By integrating CNC linear robots and fixed workbenches, it ensures seamless foaming for polyurethane seals and end caps, meeting the highest standards of quality and performance.

How It Works:

The JHT20/30 Series dispenses and mixes two-component polyurethane materials. The system pours miscible liquids into flat workpieces, sockets, or molds and, with the chemical reaction, a foamed sealing ring is created in place from the workpiece. If there are no visble contact points or seams in the workpiece, the foam was most likely bonded to the workpiece during the automated process.

Key Features and Benefits:

Unlike traditional low-pressure foaming machines, the JHT20/30 Series utilizes advanced automation and precision engineering, ensuring superior performance and efficiency. This design offers several key advantages:

Versatile Application Modes

Supports various application scenarios, including flat surfaces, sockets, and molds.

Top-Notch Sealing Performance

Provides airtight, waterproof, dustproof, soundproof, and insulating properties.

Certified Quality

Meets UL/CE safety standards, MIL-STD-167 shockproof tests, and EN50298 waterproof and dustproof tests.

Automation and Precision

Integrates CNC linear robots for precise and efficient operation.

Durability and Reliability

Designed for long-term use in demanding production environments.

Eco-Friendly and Cost-Effective Operation

The system minimizes material waste and eliminates the need for cleaning agents, reducing both operational costs and environmental impact.

Characteristics:

- Viscosity (25℃): 500-800 mPs.

- Mixing Ratio: Adjustable from 15:1 to 1:1.

- Hardness: Shore 7-75A.

- Maximum Operating Speed: Up to 35m/min.

- CNC Acceleration: 5m/s².

- Setting Accuracy: ±0.05mm.

- Outflow Range: 0.05g/s to 100g/s.

- Customizable Process Sizes:

- A1: 2,500 x 1,200 x 150mm (X/Y/Z).

- A2: 1,200 x 600 x 150mm (X/Y/Z).

Application

The JHT20/30 Series is ideal for a wide range of applications, including:

- Gland strips for industrial jack boxes.

- Sealing solutions for lamps and lanterns.

- Interior and exterior trims in automobiles.

- Engine components requiring precision sealing.

Why Choose the PU Gasket Dosing Machine?

The JHT20/30 Series PU Gasket Dosing Machine stands out for its advanced technology, automation capabilities, and exceptional sealing performance. It is the ideal solution for industries requiring high-quality polyurethane foaming applications, ensuring reliability, efficiency, and compliance with international standards.