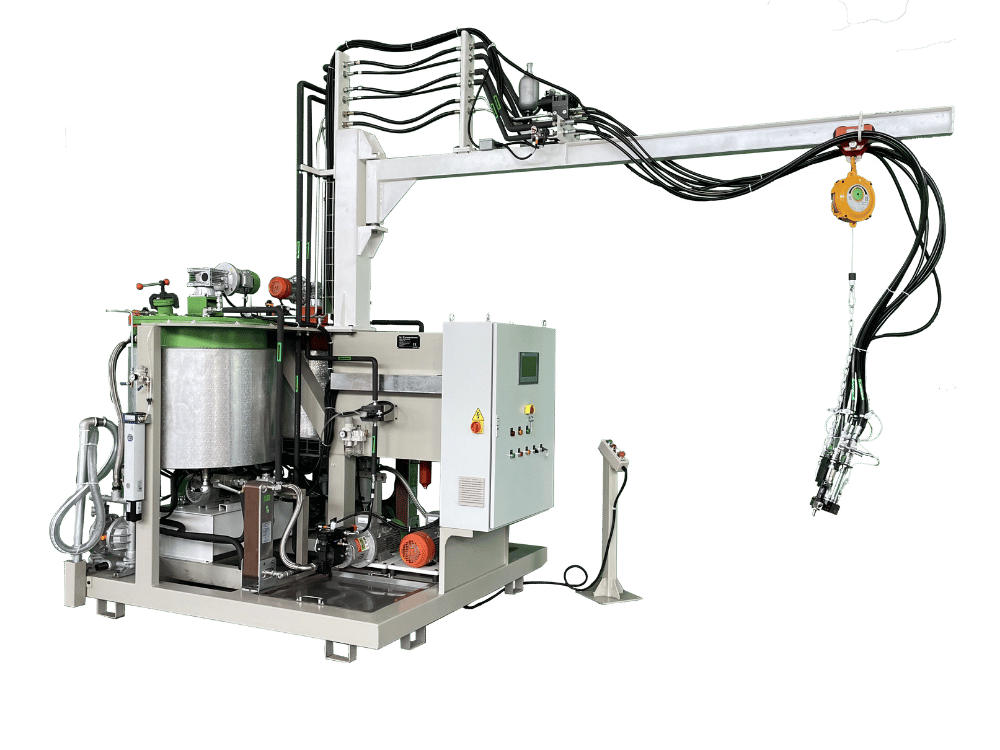

Polyurethane Casting Machine

Tailored Polyurethane Casting Machines for Your Needs

Elastomer products demand precision, durability, and advanced technology. With over 30 years of expertise in polyurethane casting technology and customer collaboration, we specialize in delivering customized polyurethane casting machines designed to meet your unique production requirements.

Whether you need specific configurations, enhanced durability, or optimized performance, our tailored solutions ensure efficiency, reliability, and superior product quality. Let us help you achieve your production goals with machines built to your exact specifications.

Reliable Polyurethane Machine Supplier from China

Having served and supplied more than 200 clients and companies and with over 30 years of experience in the business, Zhejiang Henghui Machinery Co., Ltd. is one of the most trusted and reputable leaders in the manufacturing of Polyurethane Equipment.

The machines are reliable, accurate, and consistent in performance.

With ISO 9001 Certification, we offer our clients predefined active solutions and an all-encompassing support system, ensuring seamless production.

Contact Us Now

Enter your inquiry details, We will reply you in 6 hours.

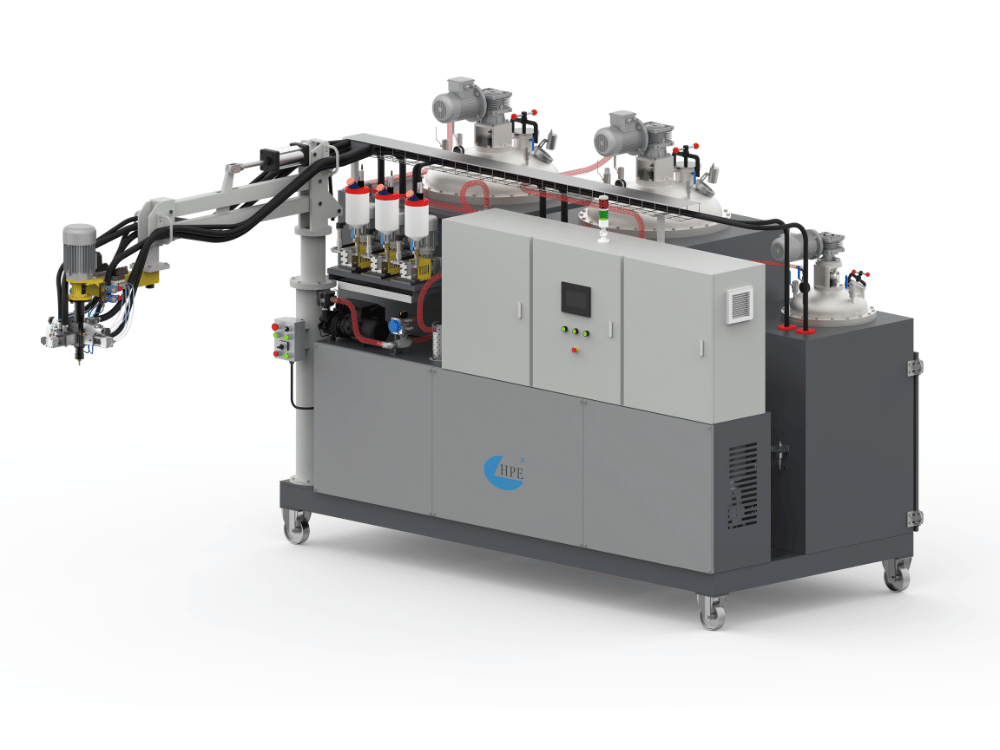

Advanced Polyurethane Casting Machines for Elastomer Production

These casting machines are provided with high precision and easy accessibility features. The versatility of Henghui casting machines makes them equally effective for the production of two- and three-component polyurethane elastomers. Operational efficiency, minimal material waste, and high productivity are achieved within an eco-friendly production framework.

Henghui Machinery is a 9001-certified company with a reputation for excellence, built on 30 years of experience, eco-friendly automation, advanced engineering, and the production of durable polyurethane elastomer casting machines. Small and large, industrial, and batch production setups are made with mechanised versatility for heterogeneous production.

Polyurethane Casting Machine: From Basics to Applications

The polyurethane casting machine is a versatile, widely used piece of equipment in the manufacturing industry, particularly for the production of polyurethane-based products. This advanced machine plays a crucial role in transforming raw materials into a wide range of products, from industrial components to consumer goods.

But what exactly is a polyurethane casting machine? How does it operate? And what are its applications? In this section, we’ll explore the fundamentals of polyurethane casting machines, delving into their key components, operational principles, and the diverse applications that benefit from their capabilities.

What is a Polyurethane Casting Machine?

A polyurethane casting machine is specialized equipment designed to process and cast polyurethane materials into various products. Unlike other casting systems, the polyurethane casting machine is specifically engineered to handle the unique chemical reactions and properties of polyurethane, ensuring precision and efficiency in production.

The machine typically consists of several key components, including a mixing head, metering pumps, and a mold system. The mixing head ensures thorough blending of the raw materials, such as polyol and isocyanate, which are essential for the chemical reaction that forms polyurethane. Metering pumps control the precise ratio of these materials, while the mold system shapes the polyurethane into the desired product.

What sets a polyurethane casting machine apart is its ability to produce high-quality products with consistent properties. Its precision, efficiency, and adaptability make it suitable for manufacturing a wide range of polyurethane products, from industrial components like seals and gaskets to consumer goods such as wheels and furniture parts.

The Significance of Polyurethane Casting Machines in Manufacturing

In the manufacturing industry, polyurethane casting machines play a crucial role in producing high-quality polyurethane products. These machines are specifically designed to ensure precision and consistency, which are essential for meeting the diverse needs of various industries.

Polyurethane casting machines are widely used in industries such as automotive, construction, electronics, and medical. In the automotive sector, they are instrumental in manufacturing components like seals, gaskets, and bushings. In construction, polyurethane products, such as insulation materials and coatings, are produced using these machines. The electronics industry benefits from polyurethane casting machines for creating protective casings and encapsulations, while the medical field relies on them for prosthetics and medical device components.

The ability of polyurethane casting machines to deliver consistent, uniform products makes them indispensable. By maintaining precise control over the production process, these machines ensure that the final products meet stringent quality and performance standards, making them a cornerstone of modern manufacturing.

Understanding the Difference Between Polyurethane Casting Machines and Other Casting Systems

Compared to other casting methods, such as injection molding and compression molding, polyurethane casting machines offer several distinct advantages. These machines are specifically designed to handle the unique chemical reactions and properties of polyurethane, making them a preferred choice for manufacturing high-quality polyurethane products.

One key difference lies in the design and operation. Injection molding, for example, relies on high pressure to inject molten material into a mold, while compression molding uses heat and pressure to shape materials. In contrast, polyurethane casting machines focus on precise metering and mixing of raw materials, followed by controlled pouring into molds. This process ensures uniformity and consistency in the final product, which is critical for applications requiring high performance and durability.

Polyurethane casting machines also stand out for their efficiency, precision, and versatility. They can produce a wide range of products, from industrial components to consumer goods, with minimal material waste. Additionally, these machines are highly adaptable, allowing manufacturers to customize production parameters to meet specific product requirements.

In summary, the advanced design, operational precision, and adaptability of polyurethane casting machines make them superior to other casting systems for producing high-quality polyurethane products with consistent properties and performance.

Polyurethane Casting Machine Elements

The polyurethane casting machine is a sophisticated piece of equipment with several key components that work together to ensure efficient and precise production of polyurethane products. Here’s a breakdown of its main elements and their functions:

Mixing Head

The mixing head is a critical component that ensures precise mixing of polyurethane components, including polyol, isocyanate, and additives. Proper mixing is essential to initiate the chemical reaction that forms polyurethane, ensuring uniformity and consistency in the final product.

Metering System

The metering system controls the accurate dosing of raw materials, maintaining the correct ratio of components. This precision is vital for achieving consistent product quality and preventing defects caused by improper chemical proportions.

Heating System

The heating system maintains the optimal temperature required for the chemical reaction and material flow. By ensuring consistent temperature control, this system prevents issues such as incomplete reactions or material blockages that could compromise product quality.

Mold System

The mold system shapes the polyurethane into specific forms or products. Whether producing industrial components, consumer goods, or custom designs, the mold system ensures precision and uniformity in the final output.

Control Panel

The control panel monitors and adjusts production parameters, such as temperature, pressure, and mixing ratios. This component ensures precision and efficiency throughout the production process, allowing operators to maintain consistent quality and adapt to specific production requirements.

Conveyor System

The conveyor system transports raw materials and finished products through the production process. It ensures a smooth and continuous workflow, improving overall efficiency and reducing manual handling.

By understanding the functions and interactions of these key components, manufacturers can optimize the performance of polyurethane casting machines and achieve consistent, high-quality results across a wide range of applications.

How Does a Polyurethane Casting Machine Work?

Polyurethane casting machines are marvels of engineering, designed to precisely mix and cast polyurethane materials into molds, ensuring consistent quality and performance. Let’s break down the process step by step to understand how these machines operate:

1. Material Feeding

The process begins with the introduction of raw materials—typically polyol, isocyanate, and any required additives—into the system. These components are stored in separate tanks or hoppers and are fed into the machine through an automated feeding system. This ensures a steady, controlled flow of materials, which is critical for maintaining consistency throughout the production process.

2. Mixing and Dosing

Once the raw materials enter the system, they are transferred to the mixing head. Here, the magic happens: the materials are combined in precise proportions to initiate the chemical reaction that forms polyurethane. The machine’s metering system plays a vital role in this step, ensuring that each component is dosed accurately. This precision is essential to avoid defects and achieve the desired properties in the final product.

3. Mold Filling

After mixing, the polyurethane material is ready to be cast. The machine pours the mixture into pre-prepared molds, ensuring even distribution and complete filling of every cavity. This step is crucial for creating products with precise shapes and uniformity, whether it’s a small intricate part or a large industrial component.

4. Curing and Solidification

Once the material is in the mold, it undergoes a curing process. The machine’s heating system maintains the optimal temperature to facilitate the chemical reaction, allowing the polyurethane to solidify and develop its final properties, such as strength, flexibility, and durability. The curing time can vary depending on the specific formulation and product requirements.

5. Demolding and Finishing

After curing, the solidified product is carefully removed from the mold. At this stage, additional finishing steps may be required, such as trimming excess material, polishing surfaces, or conducting quality inspections. These finishing touches ensure that the product meets the required specifications and is ready for its intended application.

By following these meticulously designed steps, polyurethane casting machines enable the efficient production of high-quality polyurethane products. From automotive parts to industrial components, these machines are indispensable across a wide range of industries, delivering precision and reliability at every stage of the process.

Advantages of Polyurethane Casting Machines

Polyurethane casting machines offer several distinct advantages, making them a preferred choice for manufacturing high-quality polyurethane products. Let’s explore some of the key benefits they provide:

- Precision and Consistency: Polyurethane casting machines are designed to ensure uniform product quality by maintaining precise control over the mixing and dosing of raw materials. This precision eliminates inconsistencies, resulting in products with consistent properties and performance, which is critical for demanding applications.

- High Efficiency: Optimized for large-scale production, polyurethane casting machines enable manufacturers to produce high volumes of products with minimal downtime. Automated processes, such as material feeding, mixing, and mold filling, enhance productivity and reduce manual intervention, making these machines ideal for meeting high-demand requirements.

- Versatility: One of the standout features of polyurethane casting machines is their ability to produce a wide range of products. From industrial components like seals and gaskets to consumer goods such as wheels and furniture parts, these machines can handle various formulations and product specifications, offering unmatched versatility.

- Cost-Effectiveness: By reducing material waste and operational costs, polyurethane casting machines provide significant cost savings. Precise dosing and efficient use of raw materials minimize errors and defects, ensuring maximum yield and making these systems highly economical for manufacturers.

- Customizability: Polyurethane casting machines are highly adaptable to specific product requirements. Manufacturers can easily adjust parameters such as material ratios, mold designs, and production settings to create customized products tailored to diverse applications, enhancing their market competitiveness.

- Environmental Benefits: Modern polyurethane casting machines support sustainable practices by reducing material waste and energy consumption. Many systems are designed to minimize emissions and incorporate recycling capabilities, contributing to a more environmentally friendly manufacturing process.

These advantages make polyurethane casting machines an indispensable tool for manufacturers seeking precision, efficiency, and sustainability in producing high-quality polyurethane products for various industries.

Applications of Polyurethane Casting Machines

Polyurethane casting machines are versatile and essential tools used across numerous industries. Their ability to precisely mix and dispense polyurethane materials allows for the creation of a vast array of high-quality products. Let's explore some of the key industries where these machines make a significant impact.

1. Automotive Industry

Polyurethane casting machines are crucial in the automotive sector for producing a wide range of components. They are used to manufacture parts that require durability, flexibility, and resistance to wear and tear. Key applications include creating seals, gaskets, and bushings that prevent leaks and reduce vibration. These machines also produce interior components like steering wheels, armrests, and dashboard elements, offering a combination of comfort and longevity.

2. Construction Industry

In the construction field, polyurethane casting machines provide solutions for insulation, adhesion, and protection. They are used to create high-performance rigid foam insulation panels, which improve the energy efficiency of buildings. Additionally, these machines produce strong adhesives and sealants for bonding various construction materials. They also help in manufacturing durable coatings that protect surfaces from corrosion, weathering, and abrasion.

3. Electronics Industry

The electronics industry relies on polyurethane casting for the protection of sensitive components. The process, known as encapsulation or potting, involves filling an electronic assembly with a polyurethane compound. This shields the components from moisture, shock, vibration, and thermal stress. Casting machines ensure a void-free encapsulation, which is vital for the reliability and long-term performance of electronic devices.

4. Medical and Healthcare

Polyurethane casting machines play a vital role in medical and healthcare applications due to the biocompatibility and versatility of polyurethane materials. They are used to produce custom prosthetics and orthotics that are both lightweight and strong. These machines also manufacture a variety of medical devices and components, including tubing, catheters, and cushioning materials for patient comfort and support.

5. Consumer Goods

From furniture to footwear, polyurethane casting machines are instrumental in manufacturing everyday consumer products. They are used to create comfortable and durable cushioning for sofas and chairs, as well as the soles of athletic and casual shoes. In the world of sports, these machines help produce equipment like skateboard wheels and protective gear, where impact resistance and performance are key.

With their precision, efficiency, and ability to handle diverse formulations, polyurethane casting machines continue to be indispensable. They drive innovation and enable the production of high-quality, durable products across a wide spectrum of industries.

Polyurethane casting machines are remarkable pieces of equipment that have transformed manufacturing across a wide range of sectors. From automotive and construction to electronics and healthcare, these versatile machines have demonstrated their value through precise material handling, high output rates, and the ability to work with diverse polyurethane formulations.

Whether you aim to produce durable, high-quality components, create intricate designs with specific properties, or enhance your production efficiency, a polyurethane casting machine could be the key to unlocking new potential for your business.

If you are looking for a specific casting machine and need guidance to choose the right equipment for your needs, please get in touch with us now.