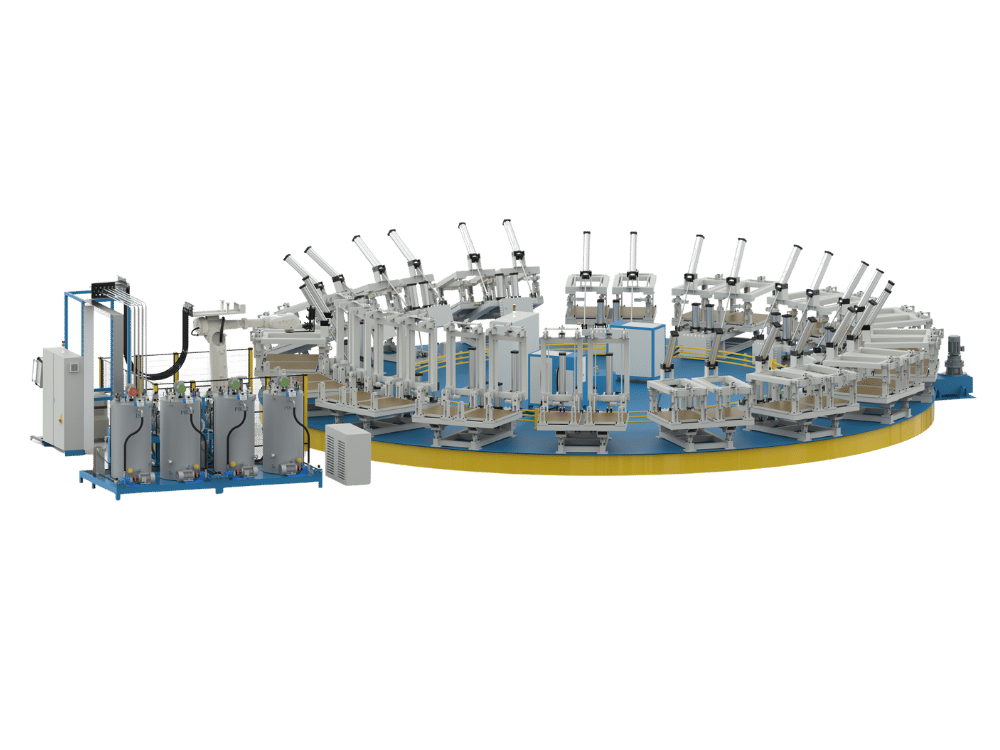

Polyurethane Mold Foaming Disk Production Line

Providing Polyurethane Mold Foaming Solutions

Our Polyurethane Mold Foaming Disk Production Line offers fully automated, middle- to large-scale production. The Polyurethane Mold Foaming Production Line features frequency-conversion motors, conveyor belt systems, automated protocols, and tailored production protocols. With a hot water temperature control system, the production line offers a fully integrated, robot-controlled automated production sequence: spraying, loading, pouring, ratio clamping, heating, and pareto unlocking. The production line produces continuously without quality loss.

Trusted China Polyurethane Equipment Manufacturer

Zhejiang Henghui Machinery Co., Ltd. is a top player in the Polyurethane Equipment Company. With its headquarters in Zhejiang, Henghui was founded in 1999. It has been ISO 9001:2000 certified since 2003 and produces more than 100 sets a year. Currently, more than 2,500 systems are in operation worldwide. The company offers a phenomenal engineering team and assembled systems to deliver creative systems to help Polyurethane Equipment meet your production needs.

Contact Us Now

Enter your inquiry details, We will reply you in 6 hours.

Polyurethane Mold Foaming Solutions

The Polyurethane Mold Foaming Disk Production Line is designed for medium to large batch sizes and is a fully automated, engineered, high-tech production system. This system achieves and maintains a high level of quality consistently while maximizing efficiency and minimizing human labor.

How It Works:

The system uses a conveyor driven by a frequency conversion motor, along with pneumatic carriers for the molds. Lifting air locks the molds, and hot water flows through the molds to keep the temperature constant. A PLC controls the complete system to automate and run continuously.

With industrial robot automation, the production line fully integrates the following operations:

- Application of release agents

- Loading and pouring of the content

- Adjustment of the pouring ratio

- Clamping of the mold/jig

- Heating and curing of the foam

- Unlocking the mold and releasing the carrier

The process is completed with manual discharge of the product foam, and reliable cyclic operation is ensured throughout each complete production run.

Key Features and Benefits:

Unlike traditional low-pressure foaming systems, this production line integrates advanced automation and precision engineering, ensuring superior performance and efficiency. This design offers several key advantages:

Advanced Automation

PLC control and robotic integration streamline production processes, reducing labor requirements and improving overall operational efficiency.

Precision Engineering

Ensures consistent material distribution and high-quality results, minimizing defects and ensuring uniformity across all products.

Temperature Control

Hot water circulation maintains optimal mold conditions, ensuring superior product quality and consistent curing results.

Durable Components

Includes a polyurethane foaming machine, mold carrier/cassette, industrial robot, and mold temperature unit, all designed for reliable and long-term performance in demanding production environments.

Versatile Applications

Ideal for manufacturing medium to large-sized polyurethane products, catering to industries such as automotive, construction, furniture, and consumer goods.

Eco-Friendly and Cost-Effective Operation

The system minimizes material waste and reduces the need for cleaning agents, lowering operational costs while supporting environmentally sustainable production practices.

Why Choose This Production Line?

The Polyurethane Mold Foaming Disk Production Line stands out for its advanced automation, precision, and adaptability. It is the perfect solution for businesses seeking efficient, high-quality production of medium to large-scale polyurethane products.