Polyurethane Sandwich Panel Line (Continuous)

Providing Reliabile Polyurethane Sandwich Panel Production Solutions

Our LD Series Polyurethane Sandwich Panel Continuous Production Line is an advanced, efficient system for producing a wide range of polyurethane (PU) panels. These panels are ideal for enclosing and decorating the outer walls of high-rise buildings due to their heat-retention and flame-retardant properties, as well as their soundproofing and environmentally friendly qualities. Production involves the continuous, automated spraying of polyurethane foam, which is then cured and cut to size while the line remains fully operational.

Trust Polyurethane Equipment Supplier China

Founded in 1999, and an ISO 9001: 2000 certified company since 2003, Zhejiang Henghui Machinery Co., Ltd. is a leading company in the polyurethane machinery manufacturing. Today, we manufacture over 100 sets of polyurethane equipment each year. More than 2,500 systems are installed worldwide. Our engineering team is focused on providing the best-value solution that meets your business and production needs.

Contact Us Now

Enter your inquiry details, We will reply you in 6 hours.

LD Series

Advanced Polyurethane Sandwich Panel Continuous Production Line

The LD Series Polyurethane Sandwich Panel Continuous Production Line is an innovative system for the continuous production of polyurethane (PU) panels. These lightweight, eco-friendly panels offer excellent thermal insulation, are flame-resistant, soundproof, and waterproof. They are also widely used in the construction industry for the exterior walls of high-rise and high-grade offices.

The production involves continuous, automated spraying of layer upon layer of polyurethane foam onto a moving substrate. During the curing of the foam and the polymerization reaction, the panels fully form. Once the panels are fully formed, the production line continues moving as the panels are cut to the desired length.

This polyurethane composite panel production line mainly consists of an upper and lower uncoiling system, a preheating device, an auxiliary device for the foaming system, a high-pressure foaming system, a double-track system, a double-track heating system, a cutting system, a stacking system, and an electric control system.

The LD Series production line does not stop at any point in the process, including automated, fine-tuned synchronization across the entire system. This process begins as the coil of material is uncoiled. This is followed by a preheating step and continuous spraying of polyurethane foam, which is fully cured as the substrate is moved along the double track through the foam layer. Once the moving substrate is complete, the double-track cutting system produces the desired panel output without disruptions.

Comprehensive Sandwich Panel Production System

From Uncoiling to Stacking, Ensuring Precision, Efficiency, and High-Quality Output

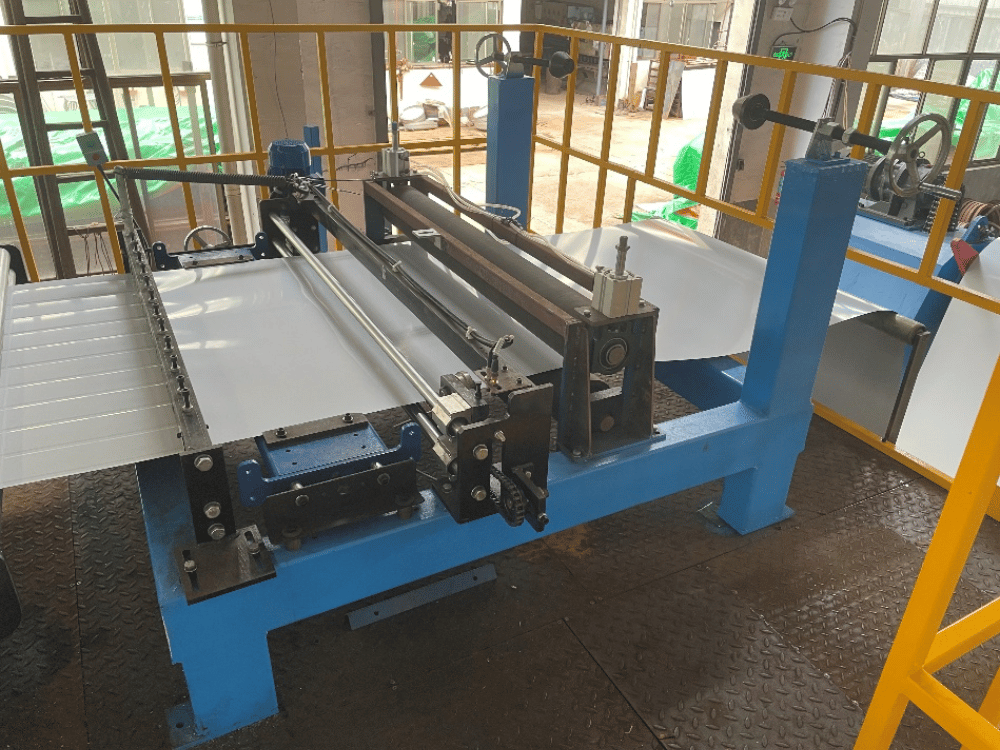

1. Uncoiler and Coil Car

- Two units are needed for Upper Coil and Lower Coil operation.

- The steel sheet (coil) is mounted on an uncoiler by the coil car, at which point 4 wedges are expanded, then fixed by hydraulic power, and finally driven by a motor.

2. Roll Forming Machine

- The upper roll forming unit is primarily responsible for shaping the forms of both sides of the lower coil (steel sheet) for the use of the roof & wall panels’ joint parts.

- The Lower roll forming unit forms, Roof 4 rib, and Cold room panel

- Types for installation are movable rail type

- Roll driving is motor driving.

3. Pre Heating

This unit preheats the upper and lower steel sheets to a moderate temperature after the roll-forming process. As polyurethane reacts chemically at low temperatures, the heating process for the steel sheet activates PUR, strengthening the adhesive bond between the steel sheet and PU foam.

4. Foaming Portal and PU Pouring

- The oscillating movement of the mixing head aims to achieve optimal application of the PUR mixture onto the lower-facing layer.

- The mixing head is actuated by a swing device, providing a free, programmable oscillating movement across the entire panel width.

5. PU Metering Machine

One of the most essential parts of the sandwich panel line is the PU foaming machine.

Panel quality depends on the PU machine’s performance.

The PU foaming machine consists of a pump for:

- Iso

- Polyol

- Catalyst

- Blowing agent (like Pentane)

Depending on the number of catalysts used, the components of the PU machine are determined. 4-6 component machines are mainly used.

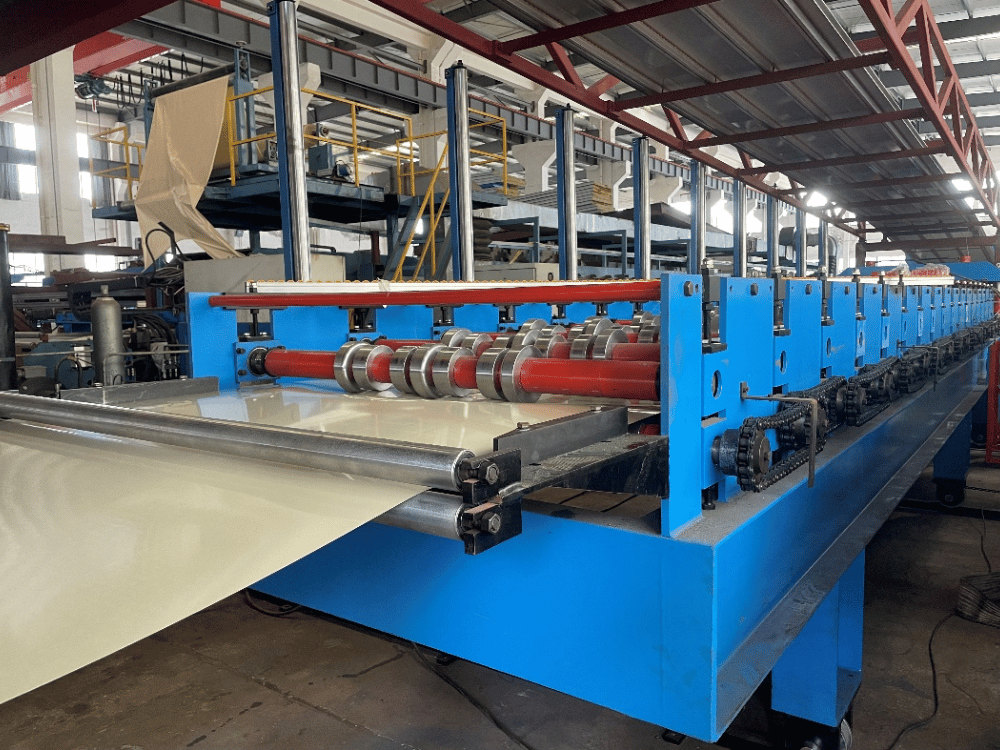

6. Double Belt Conveyor

- The PU foam component mixture applied to the lower facing layer is conveyed in synchronization with the upper facing layer along the double belt for curing.

- This unit is a crucial part and plays a core role in ensuring the highest standards of sandwich panels.

- This unit principally consists of driving motion, upper and lower slats, a hydraulic cylinder or screw motors to contain the rising pressure, and a side guide and dice block to prevent PUR foam from leaking out of the sides.

Heating system for double conveyor

- PU foam dispensed between the upper and lower coils undergoes a perfect chemical reaction and curing process at a regular temperature.

- This unit is designed to provide heated air to maintain a consistent temperature for this process.

Side Guide and PE Block System

This unit is designed to prevent PU foam from laterally leaking out of the panel using PE blocks and to maintain uniform foaming. At the same time, the double belt conveyor applies the PU foaming pressure and conveys the PU panel.

7. Cross cutter (Band saw + Disk saw)

- The perfect cutting unit must have its cutting speed synchronized with the panel conveying speed.

- This cutting unit has to be operated manually or automatically.

- The gantry is set at the rear, and the saw unit is positioned at the right-hand side as viewed from the direction of production.

8. Stacker

- This process is designed to stack finished panels efficiently at the production speed.

- The stacking speed mustn’t be slower than the panel production speed.

- It is possible to stack panels by an automatic or manual operation.

Key Features and Benefits of PU Sandwich Panel Machines

Unlike traditional low-pressure foaming systems, the LD Series employs advanced high-pressure foaming technology and a double-track design, ensuring superior performance and efficiency. This design offers several benefits:

Continuous Production Process

Ensures seamless cutting with no interruptions.

High-Pressure Foaming System

Delivers precise mixing and consistent foam quality.

Double Track Heating System

Ensures uniform curing and optimal panel quality.

Customizable Cutting System

Allows for precise length adjustments to meet specific project requirements.

Durable and Reliable Design

Built for long-term use in demanding production environments.

Eco-Friendly Operation

Minimizes material waste and supports sustainable production practices.

Characteristics:

- High-pressure foaming system for precise mixing and consistent foam quality.

- The double-track heating system ensures uniform curing and optimal panel quality.

- Continuous production process with no interruptions during cutting.

- Customizable cutting system for precise length adjustments.

- Durable and reliable design for long-term use in demanding environments.

- Eco-friendly operations minimize material waste and support sustainable practices.

Application

- Sandwich Panels

- Boltless Panels

- Wall and Cold Room Panels

- Siding Panels

- Solar Panels

- Garage Door Panels

- TPO Panels

Why Choose the polyurethane sandwich panel machine?

What sets the LD Series Polyurethane Sandwich Panel Machine apart is its advanced technology, precision engineering, and eco-friendly design. It is the perfect solution for manufacturers who want to produce high-quality polyurethane panels as quickly and efficiently as possible.