2+2 Hot Press Machine

Providing Dependable 2+2 Hot Press Machine Solutions

2+2 Hot Press Machine, or Polyurethane Sandwich Panel Dis-Continuous Production Machine, is designed for superior production of polyurethane sandwich panels. This innovative technology uses the two-in/two-out method: while two panels are loading and unloading, the other two panels are foaming and curing. This method ensures the production phase is as continuous as possible for the most efficient outcome. This technology is most suited for panel fabrication for cold storage buildings and buildings that require high insulation. The JHC 2+2 Series is a more compact, cost-effective option compared to continuous production lines.

Most Trusted Polyurethane Equipment Manufacturer in China

Founded in 1999, Zhejiang Henghui Machinery Co., Ltd. is a leading manufacturer of polyurethane equipment. With ISO 9001:2000 certification since 2003, we produce over 100 sets of polyurethane equipment annually, with more than 2,500 systems operating worldwide. Our team of experienced engineers is dedicated to delivering innovative and reliable solutions tailored to your production needs.

Contact Us Now

Enter your inquiry details, We will reply you in 6 hours.

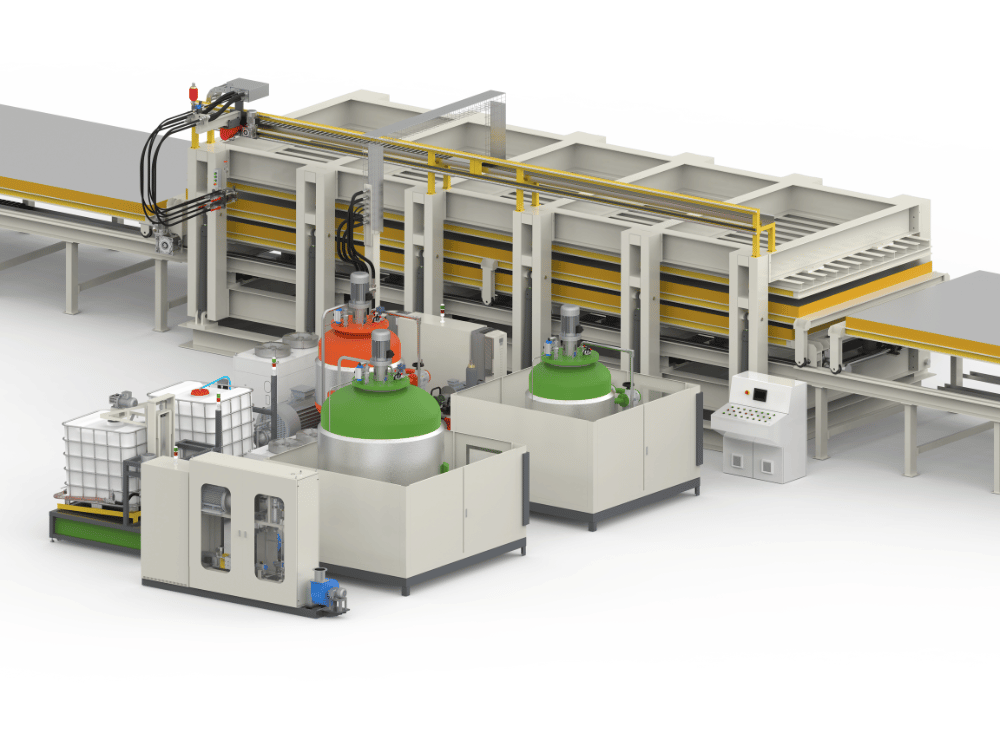

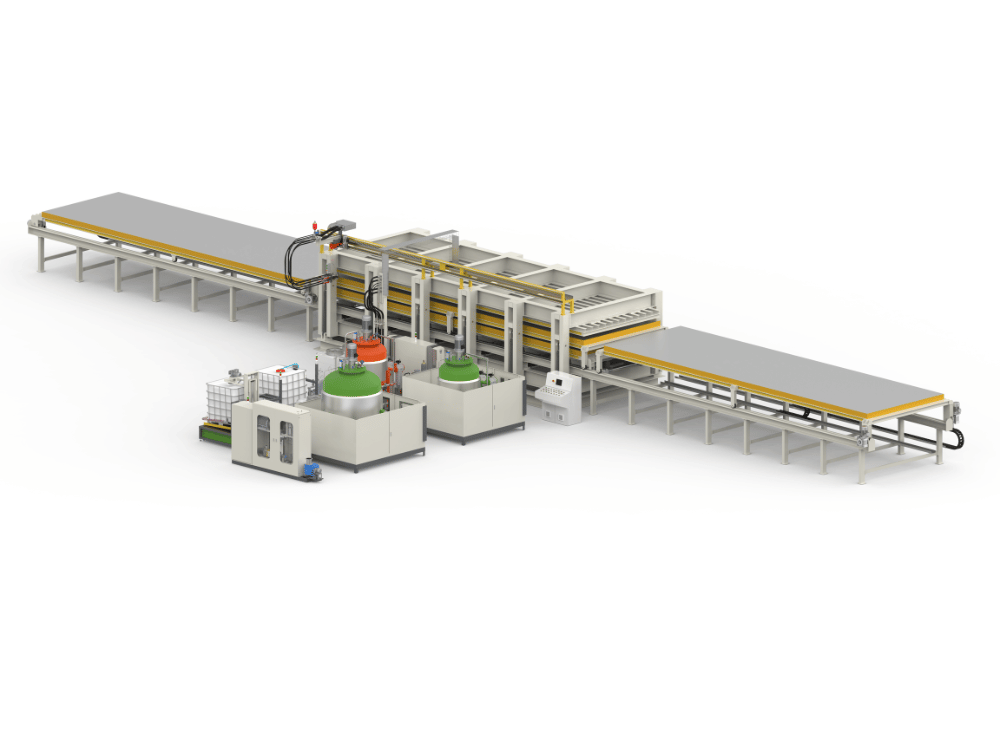

JHC 2+2 Series

Compact Polyurethane Sandwich Panel Machine

The JHC 2+2 Series Polyurethane Sandwich Panel Dis-Continuous Production Machine (or 2+2 Hot Press Machine) is built to maximize efficiency while producing polyurethane sandwich panels with exceptional quality. The two-in/two-out method is used, in which two panels are foamed and cured while two are loaded and unloaded. This sets up a production line ideal for panels used in cold storage and other high-insulation applications. Compared to other continuous production lines that take up a lot of space, the JHC 2+2 Series is a compact, cost-effective solution.

The Production Phases of the Series 2+2

The JHC 2+2 Series operates with a predetermined discontinuous production process. Production starts with injecting polyurethane foam into two panels while the other two panels are cured. During the curing stage, two more panels are loaded and unloaded to keep the system functioning without any loss in production output. Precision temperature control is essential for optimal curing, and the mold carriers maintain it through internal water-circulation channels. Smooth, consistent movement of the mold plates during operation is achieved through a rack-and-pinion synchronization mechanism, and a PLC-controlled electrical system manages the entire process, overseeing the unit’s operations, mold opening and closing, and the emergency recovery system. This process provides panels with superior insulation.

Key Features and Benefits:

Machine Frame

Welded structural steel provides robust support to meet demanding foaming requirements.

Mold Carriers

Two upper and lower mold carriers operate simultaneously and feature internal water-circulation channels. Precision-engineered with a flatness of 0.5mm and a surface roughness of Ra = 3.2 μm, they ensure maximum foaming force and consistent quality.

Synchronization Mechanism

A rack-and-pinion gear system ensures smooth and synchronized movement of the mold plates during operation.

Conveying Mechanism

Independent motors drive the mold plates for entry and exit, with speed regulated by a variable frequency drive for precise control.

Electrical Control System

PLC control manages unit operations, manual/automatic modes, emergency reset/recovery, and cycle stop functions for seamless operation.

Hydraulic System

A dual-pump system enables rapid mold opening/closing and delivers maximum clamping force for efficient production.

Characteristics:

- Welded structural steel frame for robust and durable performance.

- Two upper and lower mold carriers with internal water circulation channels for precise temperature control.

- Rack-and-pinion synchronization mechanism for smooth and uniform mold plate movement.

- Independent motors with variable frequency drive for precise mold plate entry and exit.

- PLC-controlled electrical system for seamless operation and emergency recovery.

- Dual-pump hydraulic system for rapid mold opening/closing and maximum clamping force.

Application

- Construction & Insulation: Polyurethane sandwich panels for cold storage facilities and highly insulated buildings.

- Industrial Applications: Panels for warehouses, factories, and other industrial facilities requiring thermal insulation.

- Specialized Panels: Custom panels for applications demanding high durability and insulation properties.

Why Choose the JHC 2+2 Series?

The timeless features of JHC 2+2 Series are also winning the JHC 2+2 Series the most competitive position in the global marketplace of sandwich panel production, two-in/two-out processing, advanced technology, compact design, and the productivity of one entire production line, all JHC 2+2 Series machinery.