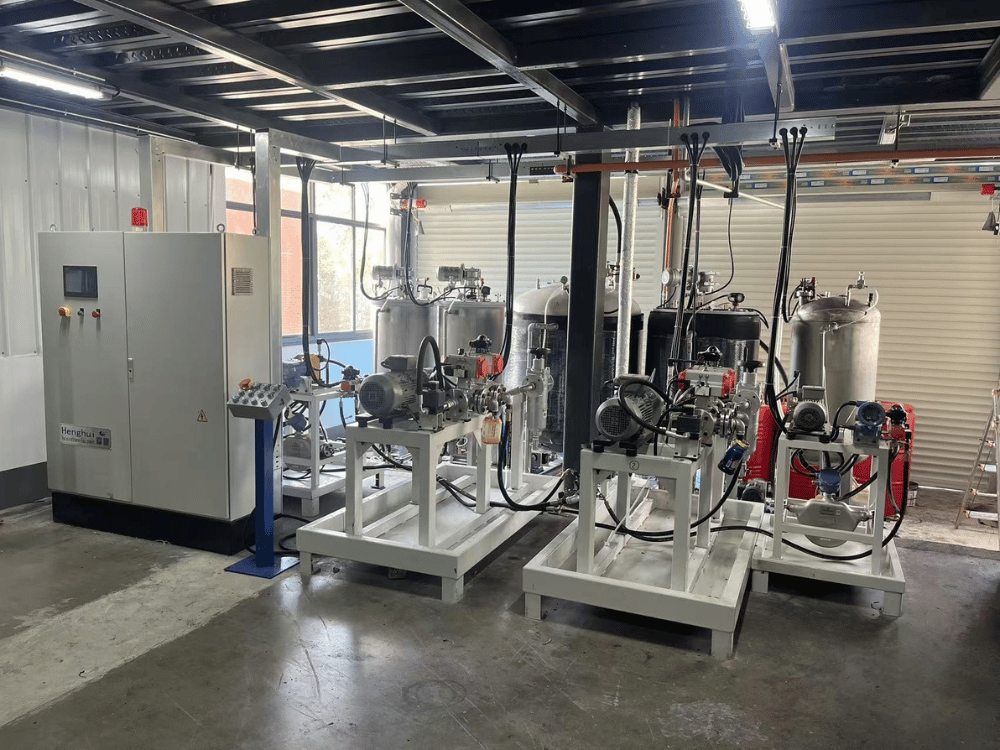

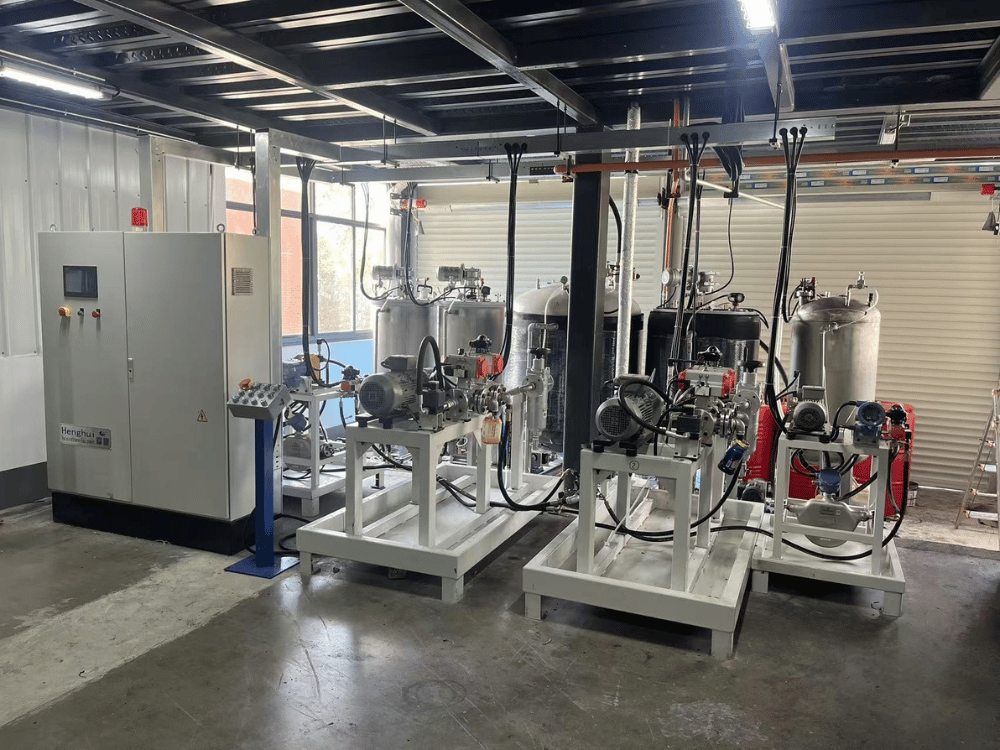

PU Premixing System for Precision and Efficiency

Your Partner for Polyurethane Premixing System Solutions

Like in automotive seat foam production and home appliance foam insulation, our Polyurethane Multiple Component Premixing Dosing System is used across various industries for its efficiency and accuracy. Fully automated, it works with different raw materials and mixing ratios. Additionally, it monitors flow rates, tracks proportions and weights, and stores data while issuing alerts for out-of-tolerance conditions to ensure smooth, efficient workflows.

Reputable Manufacturer of Polyurethane Equipment in China

In 1999, we began our journey and became Zhejiang Henghui Machinery Co., Ltd., a major player in the manufacturing of polyurethane equipment. With ISO 9001:2000 and our increased production rates — reportedly more than 100 different types of polyurethane equipment every year — we are proud of our accomplishments since 2003. With the critical contributions of our engineers, we have over 2,500 of our systems in operation worldwide, serving a variety of industries and earning a reputation for excellence and reliability.

Contact Us Now

Enter your inquiry details, We will reply you in 6 hours.

Automation of Premixing Polyurethanes

In the foam used for automobile seats and home appliance insulation, fully automatic premixing and dosing systems are essential in many other industries as well. These systems are fully automated and handle multiple primary materials and various mixing ratios. They can flow, weigh ingredients, mix, and store data for quality control tracking. Then they raise alarms for flow and weight problems or mixing data out of bounds.

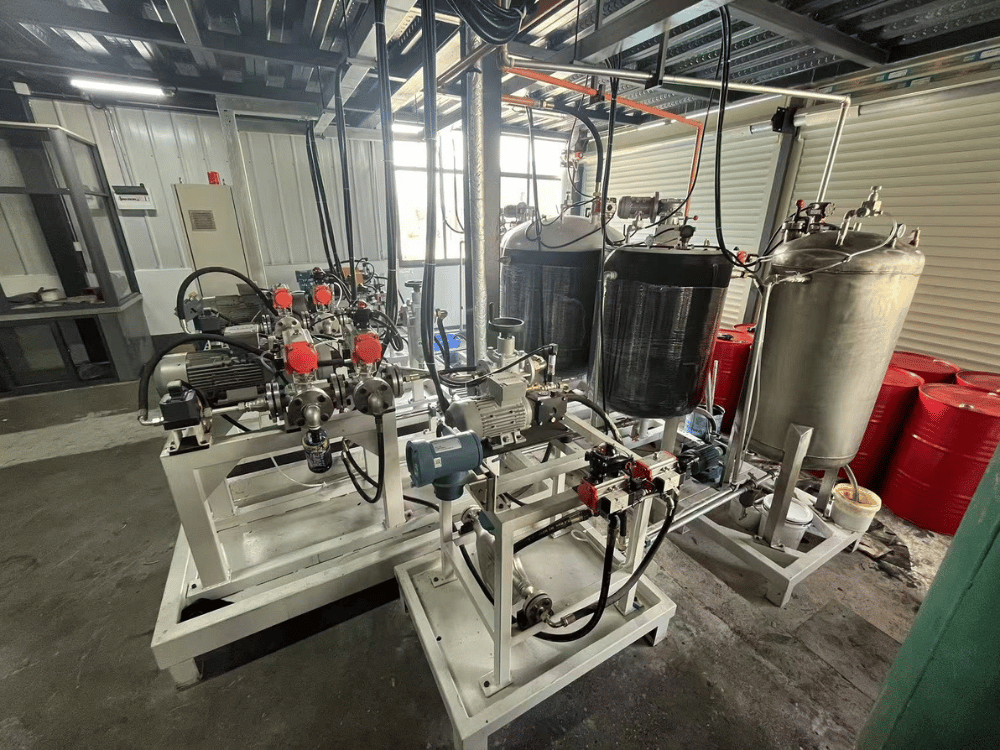

Premixing Workflow

Premises store the raw chemicals in drums or intermediate bulk containers (IBCs). Then a filling pump draws out materials and sequentially transfers them to the machine’s storage tanks. Then, the raw ingredients are driven into the mixing head of the machine using axial piston metering pumps.

In tightly controlled pressure hoses, the materials are moved into a mixing chamber where they encounter a series of increasingly constricted cones. Within restricting diffusers, the prestatic mixing is performed in a passage before dispensing. The bottlenecks and pressure differentials are uniform for high-speed aero foams and dosing machinery.

Key Features and Benefits:

Better than classical technology, modern polyurethane systems offer capabilities and efficiencies, in large part, due to fully automated design and complex integration with precision engineering in contemporary production line offerings.

Versatile Application Modes

These systems can be easily modified to fit specific situations. They can be adjusted to dispense on flat surfaces, in intricate connectors, or in casts, and can fit numerous products.

Superior Sealing Performance

The foam created has outstanding qualities. Seals can be airtight, watertight, dustproof, and also keep other materials from vibrating, and will keep things warm or cold. This quality is essential in protective coverings for electronic devices.

Automation and Precision

Using software-controlled CNC linear robots enables efficient, precise operation. This also reduces the potential of human error with the applications and increases production.

Durability and Reliability

These systems are engineered for challenging work and built to last for many years. Strong construction, along with quality parts, ensures the system will keep working without interruptions and with minimal maintenance.

Eco-Friendly and Cost-Effective Operation

The high-pressure mixing systems operate very efficiently, reducing material waste. Additionally, it reduces operating costs and the environmental impact of manufacturing processes by usually eliminating the need for harsh cleaning chemicals between operating cycles.

Enhanced Safety Features

Modern premixing systems are equipped with advanced safety mechanisms, such as automated alarms for out-of-tolerance conditions and real-time monitoring of flow rates and proportions. These features ensure safe and reliable operations, even in demanding production environments.

Characteristics:

- High-precision automated metering system

- Supports multiple mixing ratios and raw materials

- Real-time tracking of flow rates, proportions, and weights

- Data storage for mixing reports and operational logs

- Out-of-tolerance alarm system for enhanced safety

- Eco-friendly design with minimal material waste and no need for harsh cleaning chemicals

- Durable construction for long-term, reliable performance

Application

Automotive: Seat foam, headrests, armrests, dashboards, and sound insulation.

Construction & Insulation: Rigid foam panels, spray foam for thermal and acoustic insulation, and sandwich panels.

Appliances: Insulation for refrigerators, freezers, and water heaters.

Furniture & Bedding: Mattresses, sofa cushions, ergonomic office chairs, and pillows.

Consumer Goods: Toys, sports equipment (e.g., foam grips, padding), and insulated water bottles.

Why Get an Advanced System?

These premixing and dosing systems are very versatile and reliable. They have sophisticated systems that developers have fine-tuned. They are also very effective at achieving consistent results in foaming applications for polyurethanes. If your industry needs a production capacity in the medium or upper range, purchasing this technology is worth your while. These systems improve product quality and efficiency while helping maintain a competitive edge.