Fiber Reinforced Composites Solutions

Supplying You With Fiber-Reinforced Composite Solutions

Our adapted Fiber Reinforced Composite Solutions leverage new technologies such as RRIM and SCS and focus on precision and efficiency. With 30 years in the industry, we give you exactly what you need.

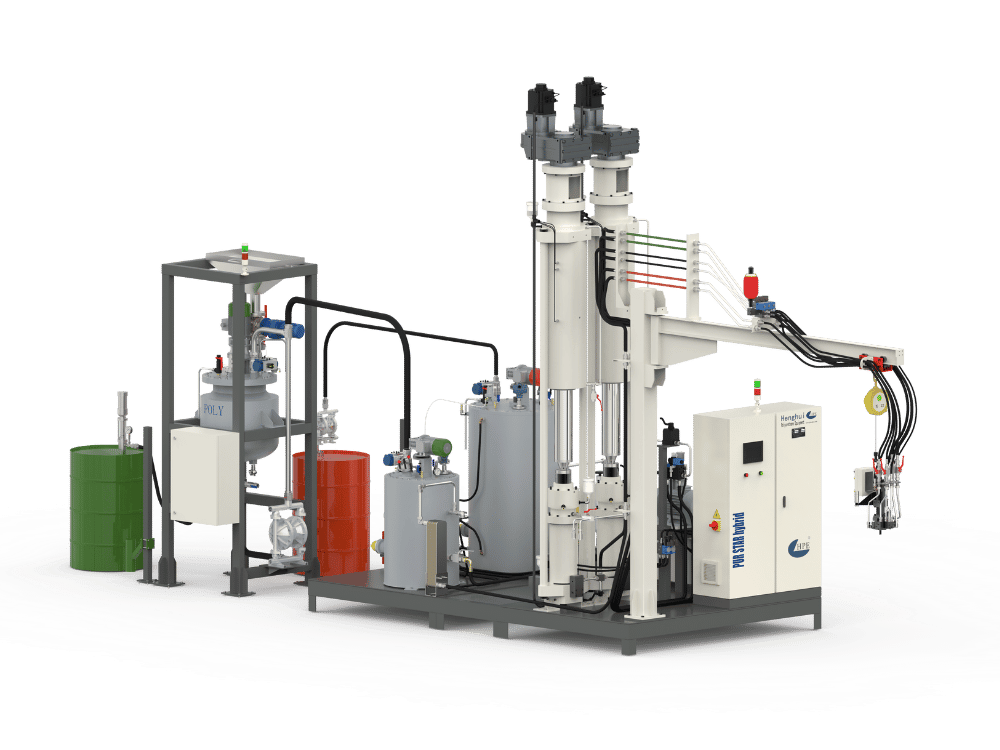

Reliable Manufacturer of Polyurethane Equipment in China

With 30 years in the industry, we have tremendous confidence in Zhejiang Henghui Machinery Co., Ltd’s expertise in the manufacturing of polyurethane equipment.

The fiber-reinforced composite solutions we offer use advanced processes such as reinforced reaction injection moulding (RRIM), structural component spraying (SCS), fibre composite spraying (FCS), long fibre injection moulding (LFI), and high-pressure resin transfer moulding (HP-RTM).

With ISO 9001 certification, we offer advanced solutions and comprehensive support to our clients, including over 2,500 active installations worldwide.

Contact Us Now

Enter your inquiry details, We will reply you in 6 hours.

Advanced Fiber Reinforced Composite Manufacturing Solutions

Zhejiang Henghui Machinery Co., Ltd offers a variety of high-end options for composite manufacturing.

The first RIM processes serve for accurate metering and mixing and are accompanied by added fillers. SCS serves for lightweight and high-strength components from fibre honeycomb panels, and FCS provides a flexible solution for low-volume production.

In LFI, continuous fibre is combined with PU in a system with high impregnation efficiency. In high-pressure RTM, it is possible to mould a resin without bubbles, which provides a high level of strength.

In addition to these technologies, there are also some production lines in support, such as the Glass Fibre Reinforced Polyurethane Foam system used for LNG insulations and the Large-Scale Composite Profile Extrusion line aimed at lightweight and high-durability industrial profiles.

These modern, precision, and efficient manufacturing technologies are aimed at contemporary manufacturing.