LFI - Long Fiber Injection Molding | Advanced Fiber Reinforcement

Provide You with Long Fiber Injection Molding (LFI) Solutions

If you need to make a high-quality, strong, and lightweight composite product, our Long Fiber Injection Moulding (LFI) processes, using more than 20 years of experience, will provide you with a reliable engineered solution for any product containing fibre-reinforced polyurethane components. We guarantee consistent and high-quality results.

Reliable Manufacturer of Polyurethane Equipment in China

Since 1999, we have been the first company in China to manufacture polyurethane equipment, and we remain at the forefront of the industry. We have more than 2,500 systems in operation worldwide and are proud to provide our customers with reliable and efficient equipment and a complete system solution. We are also pleased to hold ISO 9001:2000 certification and manufacture over 100 varieties of polyurethane equipment every year.

Contact Us Now

Enter your inquiry details, We will reply you in 6 hours.

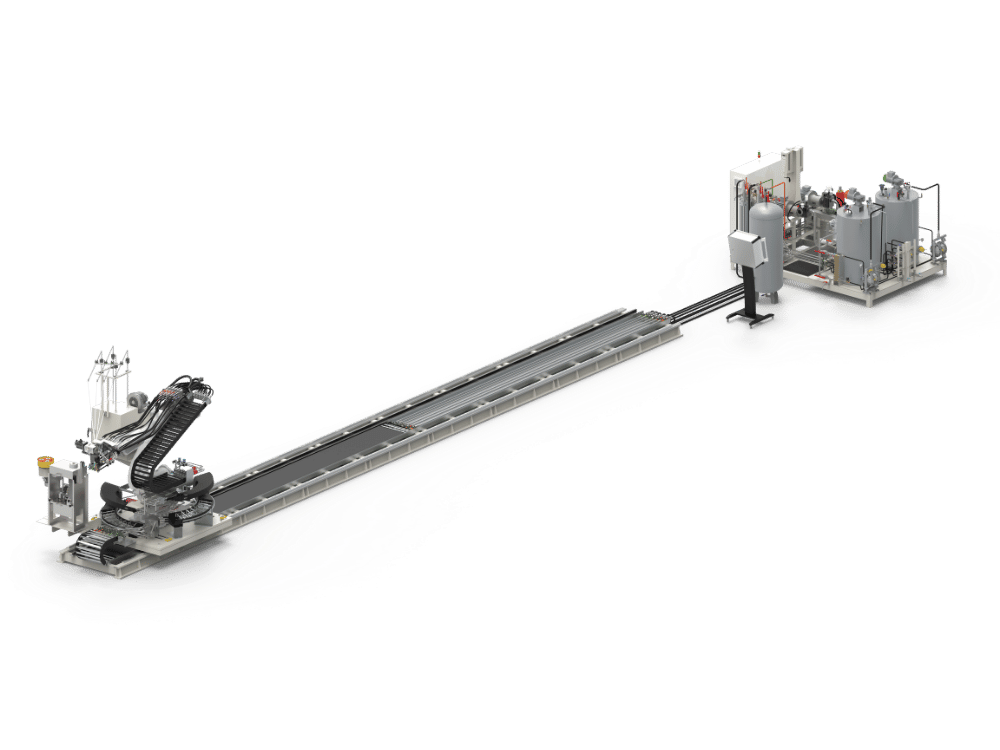

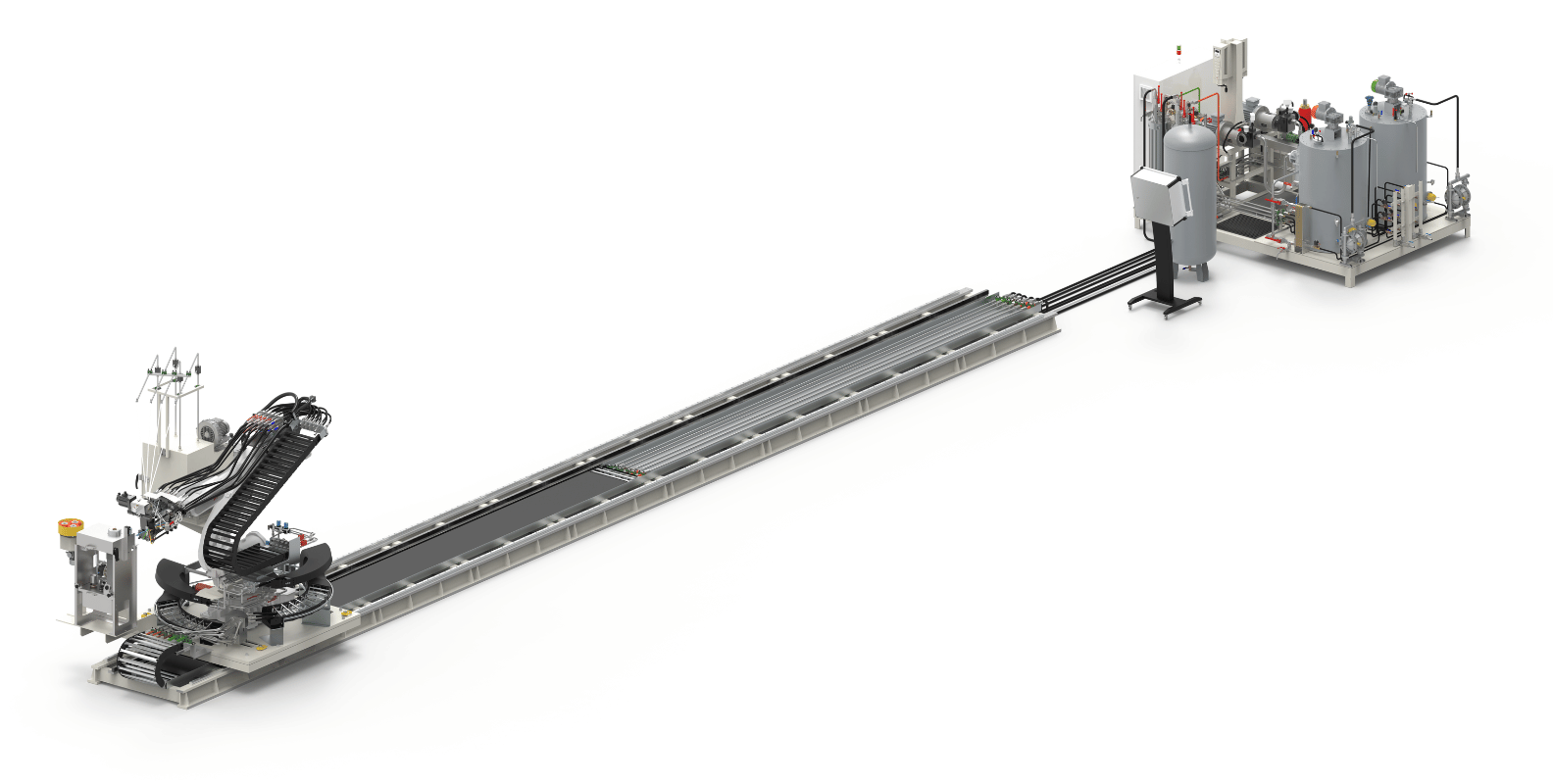

LFI System

Advanced Long Fiber Injection Molding Solutions

The Long Fiber Injection Moulding System is efficient and flexible in producing high-strength, fibre-reinforced polyurethane parts. Careful attention is given at every stage of the process, especially during the integration of continuous long fibres with polyurethane, to maintain premium quality and structure. Long Fiber Injection Moulding is excellent for furniture, automotive trim parts, significant structural components in the automotive industry, and high-strength sandwich parts that are made with composite honeycomb core layers.

.png)

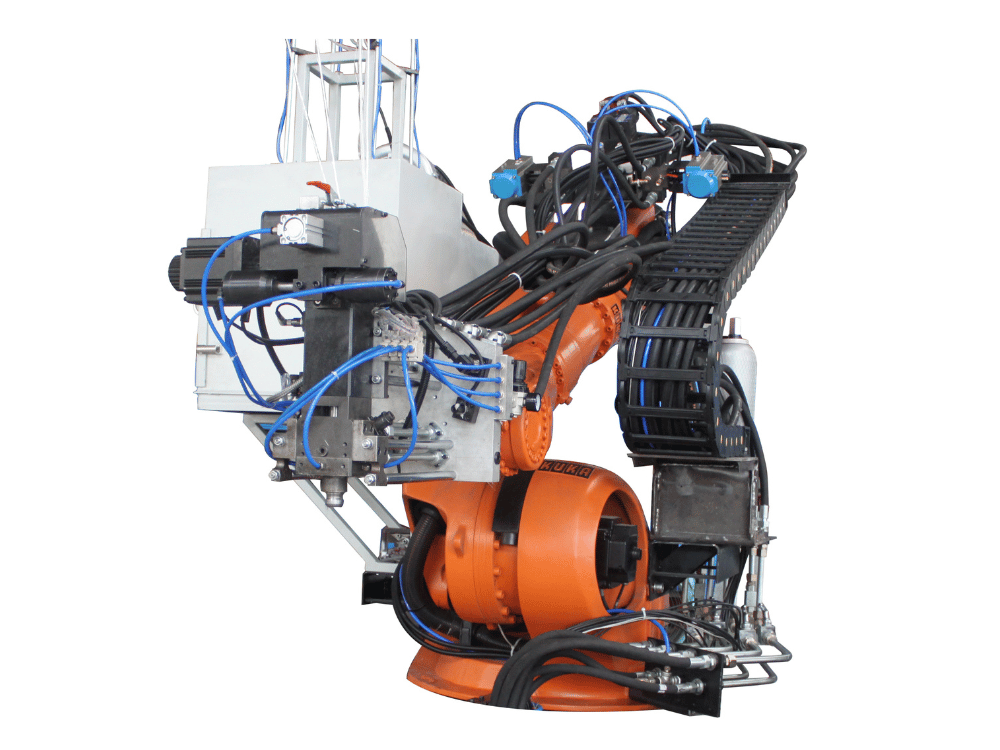

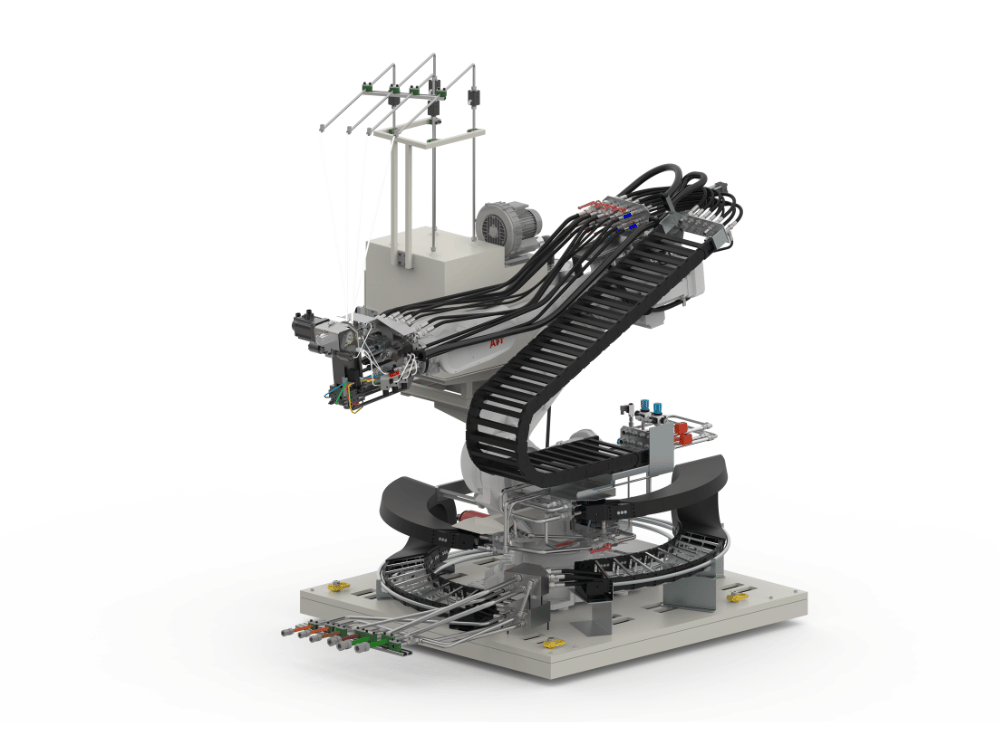

How It Works

In the Long Injection Moulding System, the ongoing long glass fibres (roving) are first fed into a cutter. They’re then blown into monofilament strands, and the glass fibres are removed for immediate PU impregnation in the mixing head. After the PU is mixed, a robot moves the fibre-filled PU to a mould, where it reacts and cures to form high-quality, durable parts. The method is innovative in that it uses minimal fibre to ensure efficient mixing.

Key Features and Benefits:

Unlike traditional methods, the LFI System employs advanced fiber injection and robotic pouring technologies. This design offers several key advantages:

Clips and Connectors Integration

Easily integrates clips and other connecting elements into the components.

Customizable Fiber Content

Fiber content and length can be adjusted locally for specific requirements.

Minimal Fiber Mixing

Ensures the final product has high strength and durability.

Excellent Surface Quality

Achieves superior surface finishes with simple process combinations, such as in-mold painting (IMP) or film applications.

Cost Efficiency

Moderate mold, machine, and raw material costs make the process highly economical.

Versatile Applications

Capable of producing compact and foamed PU systems with performance characteristics similar to SMC.

Characteristics:

- Continuous long fiber (untwisted roving) feeding system

- Cutting mechanism with blowing function for fiber division into monofilaments

- Immediate fiber impregnation with PU material in the mixing head

- Robotic pouring for precise material application into molds

- Minimal fiber mixing for high-strength components

- Moderate mold, machine, and raw material costs

- Excellent surface quality with in-mold painting (IMP) or film applications

Application

Automotive: Interior trim parts, rear sill plates, and significant three-dimensional structural components.

Construction: High-strength sandwich parts with honeycomb core layers for lightweight structural applications.

Consumer Goods: Durable, lightweight products that require high strength and excellent surface finishes.

Why is the LFI System the Best Choice?

The LFI System can create exact, high-strength, fibre-reinforced components. It is highly adaptable and consistently meets industry standards, delivering the best efficiency and lowest production costs, making it the best choice for industries that need rigid, lightweight composites. For more information on how the LFI System can improve your production line, reach out to us today!