A polyurethane casting machine is a sophisticated manufacturing tool used primarily by engineers, industrial designers, and manufacturers to produce durable, high-quality parts from polyurethane resins. These machines function by precisely metering, mixing, and dispensing liquid reactive components—typically a polyol and an isocyanate—into a mold where they cure to form a solid object. Unlike simple gravity casting, these machines use controlled pressure and temperature systems to ensure uniform chemical reaction, eliminating air bubbles and ensuring consistent material properties. They serve as the bridge between raw chemical formulations and finished products, capable of creating everything from soft, elastomeric seals to rigid, structural housings specified by technical drawings.

Polyurethane casting machines are incredibly versatile tools for both prototyping and mass production; they are used in automotive factories to create impact-resistant bumpers, by electronics manufacturers to pot sensitive components for protection, and in the medical field to produce biocompatible devices. In this guide, I’ll explain what polyurethane casting machines are, how they operate, and the diverse applications they serve across industries. Whether you are looking to set up a new production line or want to understand the technology behind standard plastic parts, this comprehensive overview will provide the insights you need to navigate the world of polyurethane casting.

What Is a Polyurethane Casting Machine?

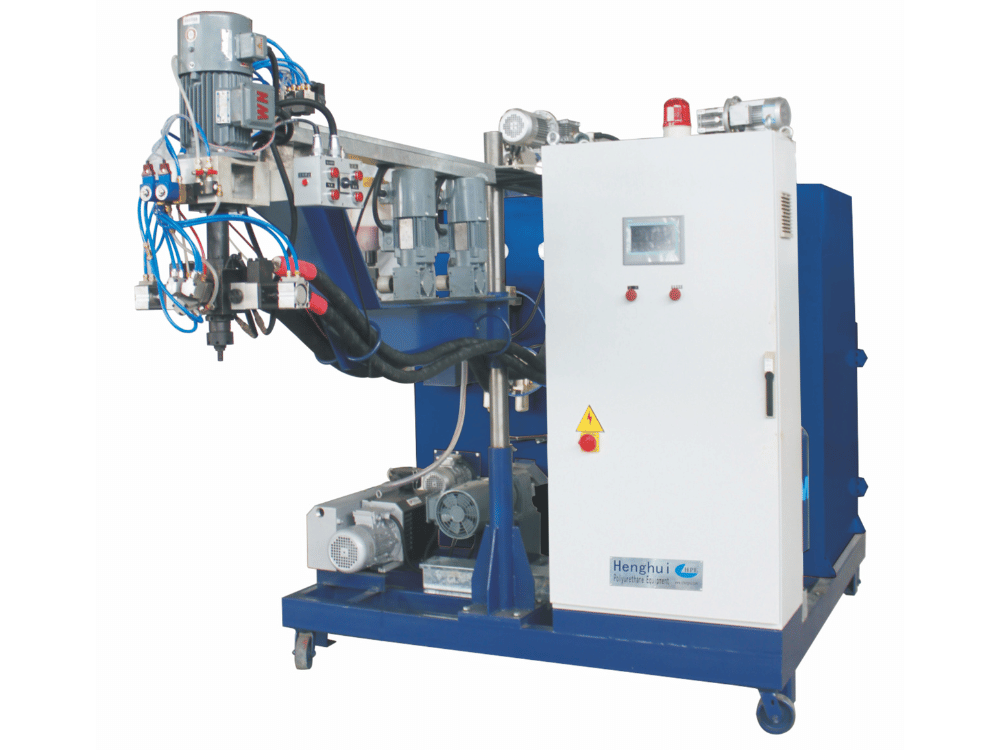

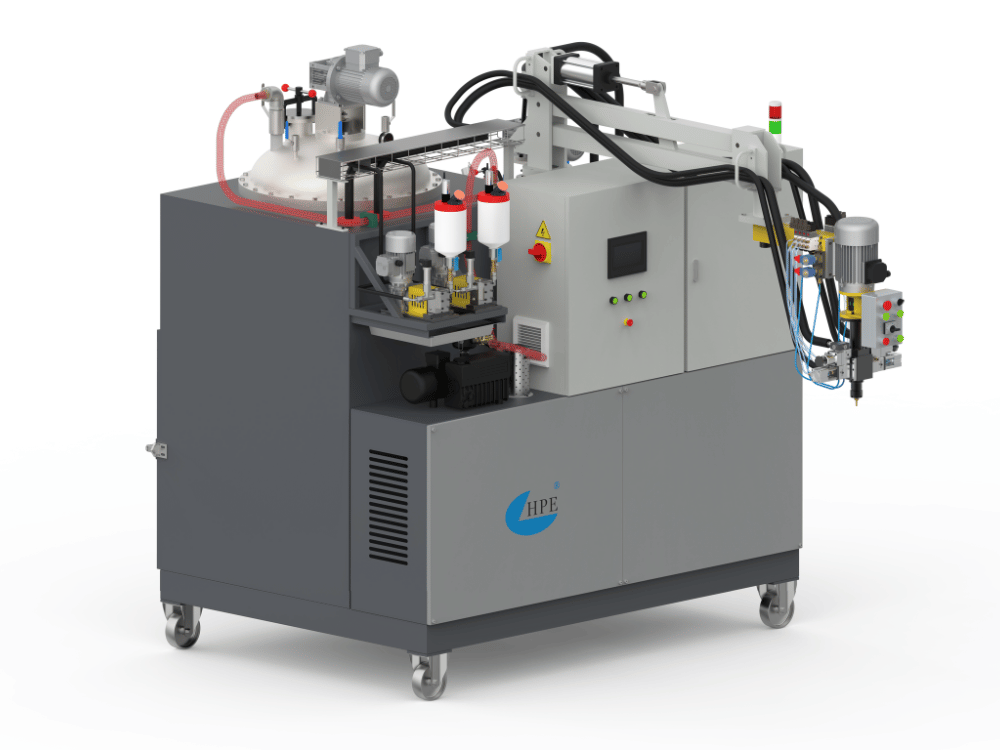

A polyurethane casting machine is specialized equipment designed to handle the unique rheology and reaction kinetics of polyurethane systems. At its core, the machine consists of storage tanks for raw materials, precision metering pumps, and a mixing head where the components meet. A manufacturer inputs specific parameters into the machine’s control unit, such as the mixing ratio and shot size, and the machine executes the casting cycle automatically. Once the parameters are set, the machine draws the liquid components from the tanks, processes them through the mixing head, and dispenses the mixture into a prepared mold. These machines are the industry standard for producing parts that require specific physical properties, ranging from high abrasion resistance to extreme flexibility.

The machine’s main components are engineered to handle the distinct characteristics of the chemicals involved. The metering system is the heart of the operation, often utilizing gear or piston pumps to ensure that the exact amount of each component is delivered to the mixing head. The mixing head itself is a marvel of engineering, designed to blend the components thoroughly in a fraction of a second before the chemical reaction begins to solidify the material. Additionally, temperature-control units are integrated into the tanks and lines to maintain a consistent chemical viscosity. At the same time, vacuum systems are often employed to degas the materials, preventing defects in the final product.

The versatility of a polyurethane casting machine allows it to produce an immense variety of products by simply changing the chemical formulation or the mold. A single machine can often switch between producing soft, rubber-like wheels for skateboards and hard, impact-resistant casings for power tools. This adaptability makes them invaluable in environments with high product diversity. They bridge the gap between low-volume manual casting and high-volume injection molding, offering a cost-effective solution for mid-range production volumes, where tooling costs need to remain manageable while still achieving industrial-grade quality.

How Does a Polyurethane Casting Machine Work?

The fundamental operation of a polyurethane casting machine revolves around the precise stoichiometry of mixing two chemically reactive liquids. The process begins with the preparation of the raw materials, usually component A (polyol) and component B (isocyanate), which are loaded into separate, conditioned tanks. The machine circulates these fluids to maintain a homogeneous temperature and consistency. When a cycle is triggered, the machine’s pumps drive the fluids through heated hoses to the mixing head. Here, they impinge upon each other at high velocities or are mechanically agitated to ensure a perfect blend. This mixture is then poured or injected into a mold, where the exothermic reaction takes over, transforming the liquid into a solid polymer.

Detailed mixing and pouring are critical phases where the machine’s precision is paramount. Inside the mixing head, the geometry is designed to create turbulence that forces the two distinct liquids to combine at the molecular level. This is often achieved through dynamic mixing with a rotating element or high-pressure impingement mixing. Once mixed, the material must be dispensed quickly before it gels or cures. The machine controls the flow rate and the “shot size”—the exact volume of material dispensed—to ensure the mold is filled without overfilling. This automated dispensing eliminates variability in hand-mixing, ensuring consistent material throughout.

Temperature and pressure play indispensable roles in the success of the casting operation. The chemical reaction that creates polyurethane is susceptible to temperature; if the components are too cold, they become viscous and mix poorly, while excessive heat can cause the reaction to accelerate uncontrollably, leading to scorching or shrinkage. The machine maintains strict thermal regulation throughout the system. Pressure is equally important, particularly in the mixing head, to ensure the components have enough kinetic energy to mix thoroughly. In some advanced processes, the mold itself is placed in a pressure chamber immediately after pouring to compress any microscopic air bubbles, ensuring a void-free, dense part.

Quality control measures are integrated directly into the machine’s operation to monitor the process’s health. Sensors continuously track the component ratios, line pressure, and tank temperatures. If any parameter drifts outside of the set tolerance, the machine can automatically alarm or halt production to prevent the manufacture of defective parts. Post-process, operators often inspect the “demold time”—how long it takes for the part to solidify enough to remove it—as a quick check of the system’s reactivity. This rigorous monitoring ensures that the physical properties of the final cast part, such as tensile strength and hardness, meet the required specifications.

Types of Polyurethane Casting Machines

There are distinct categories of polyurethane casting machines, each engineered to address specific manufacturing requirements and material formulations. The primary distinction is between low- and high-pressure systems. Low-pressure casting machines are the workhorses for applications where the mix ratio is forgiving and the materials’ viscosities are high. They typically use mechanical stirrers in the mixing head to blend the components. These machines are ideal for casting elastomers, intricate micro-parts, or scenarios requiring frequent material changes. They are generally less expensive and easier to maintain, making them a popular choice for smaller shops or specialized production lines that produce items such as shoe soles or industrial gaskets.

High-pressure casting machines, often called Reaction Injection Molding (RIM) machines, use high-velocity impingement to mix the components. In these systems, the chemical streams collide at pressures often exceeding 1,000 psi within a small mixing chamber. This method is speedy and self-cleaning, as no mechanical stirrer is required. High-pressure machines are well-suited to high-volume production runs and to faster-reacting foam systems or rigid structural parts. They are commonly used in the automotive industry to produce bumpers, dashboards, and other significant, complex components, where cycle times must be kept to a minimum to maintain efficiency.

Beyond the standard pressure-based classifications, there are specialty casting machines designed for unique or niche applications. For instance, rotational casting machines are used to uniformly coat the inside of a mold, creating hollow parts such as mannequins or soft-touch skins. There are also multi-component machines capable of handling three or more chemical streams simultaneously, allowing for the addition of colors, UV stabilizers, or fire retardants directly into the mix stream. Other specialty units are designed for vacuum casting, where the entire mixing and pouring process occurs inside a vacuum chamber to produce bubble-free, clear parts for optical applications or prototypes that mimic the properties of production thermoplastics.

Design Software for Polyurethane Casting

Just as a laser cutter relies on digital files, a modern polyurethane casting machine is part of a workflow that begins with sophisticated design software. This is not merely about drawing the part but simulating the entire casting environment. Engineers use CAD (Computer-Aided Design) software like SolidWorks or Autodesk Inventor to create the 3D geometry of the part and the mold. More importantly, they utilize rheology simulation software to predict how the liquid polyurethane will flow into the mold. This software helps identify potential air traps, weld lines, or areas of incomplete filling before any metal is cut. By simulating the flow front and curing thermal profile, designers can optimize gate locations—where the material enters the mold—and vents, ensuring a successful cast in the first physical trial.

On the operational side, software plays a crucial role in quality control and production monitoring. Modern casting machines are equipped with PLC (Programmable Logic Controller) systems that often interface with SCADA (Supervisory Control and Data Acquisition) software. This software logs every shot poured, recording data points such as component temperatures, pressures, and mix ratios for every part produced. This “digital twin” of the production run allows manufacturers to trace distinct batches and ensure consistency over time. If a defect is found in a final product, engineers can review data logs from the exact time it was cast to determine whether a machine malfunction or a material issue caused it, facilitating rapid troubleshooting and continuous process improvement.

Mold Preparation and Casting Process

The journey to a successful polyurethane part begins long before the machine dispenses any material; it starts with meticulous mold preparation. The mold, which can be made from aluminum, steel, silicone, or epoxy, must be thoroughly cleaned to remove any residue from previous cycles. The mold’s surface finish dictates the final part’s texture, so any scratches or debris will be transferred to the casting. The mold is then typically preheated to a specific temperature. This preheating is vital because pouring warm polyurethane into a cold mold can cause surface defects, skinning issues, or uneven curing. The thermal mass of the mold helps maintain the stability of the exothermic reaction, ensuring uniform physical properties throughout the part.

Once the mold is clean and at the correct temperature, applying a mold release agent is critical. Polyurethane is naturally adhesive and will bond aggressively to most mold materials without a barrier. Operators apply a thin, uniform layer of release agent—often a wax or silicone-based spray—to the interior surfaces of the mold. The application must be precise; too little release agent will cause the part to stick and potentially damage the mold during removal, while too much can pool in corners, obscuring fine details and causing surface blemishes on the finished part. This step ensures that the demolding process is smooth and efficient.

The casting process itself is a sequence of coordinated actions executed by the machine and operator. The mold is closed and positioned under the dispensing head. The operator or a robotic arm triggers the machine to dispense the pre-programmed shot size. The liquid mixture flows into the mold, filling the cavity. In open-pouring methods, the operator might manually tilt the mold to ensure the liquid reaches all corners. In closed-mold injection, the machine pumps material into the cavity until it is full. Immediately after pouring, the mold may be placed in a pressure pot or vacuum chamber to eliminate entrained air, ensuring a dense, void-free structure.

After the mold is filled, the curing phase begins. The filled mold is moved to a curing oven or left on a heated table for a specified duration. During this time, the liquid polymer crosslinks and solidifies. Once the “green strength” is achieved—meaning the part is solid enough to hold its shape but not fully cured—the mold is opened, and the part is removed. This post-casting finishing often involves trimming “flash” (excess material that leaked into the parting line) and, if needed, a secondary post-cure cycle in an oven to maximize the material’s physical properties. The mold is then cleaned and prepped for the next cycle, and the loop repeats.

Key Settings for Polyurethane Casting

Achieving the perfect cast requires a deep understanding of the machine’s settings, as even minor deviations can lead to part failure. Temperature control is the most pervasive variable. The tanks, hoses, mixing head, and mold all have optimal temperature ranges. For instance, the isocyanate component is often sensitive to crystallization at low temperatures, while polyols can become too viscous to pump accurately. The machine’s heating units must be calibrated to keep these fluids within a narrow window, typically within ±2 °C. Deviating from this affects viscosity, which in turn reduces mixing efficiency and can alter the part’s final dimensions due to thermal shrinkage.

Mixing ratios are the chemical recipe for the product and must be strictly adhered to. The ratio of polyol to isocyanate determines the reaction stoichiometry. If the machine dispenses too much isocyanate, the final part may be brittle and discolored; too much polyol, and the part may remain soft, tacky, or structurally weak. Modern machines use flow meters to constantly adjust pump speeds, ensuring the ratio stays within a fraction of a percent of the target value. Operators must regularly verify these ratios through “calibration shots,” in which the output of each stream is weighed separately to ensure the machine’s digital reading matches physical reality.

Pressure settings are critical, specifically for high-pressure or impingement mixing machines. The pressure at the injection nozzles must be high enough to create the turbulence needed for mixing but stable enough to prevent surging—low pressure results in “striations” or unmixed streaks in the material, leading to weak spots. Furthermore, the pressure within the mold cavity (if using injection) needs to be controlled to prevent “flashing, where the internal pressure forces the mold open, letting material leak out. Balancing injection pressure with the mold’s clamping force is a delicate equilibrium that ensures a clean, dimensionally accurate part.

Safety measures are integral to the machine’s settings and operation. Isocyanates are respiratory sensitizers, and the machinery operates at high pressures and temperatures. The machine settings include safety interlocks that prevent operation if the ventilation system isn’t active or if guard doors are open. Pressure relief valves are set to open when line pressure exceeds safe limits, preventing hose ruptures. Additionally, automated alarms for temperature runaways help prevent chemical decomposition or fire hazards. Operators must ensure these safety parameters are never bypassed, as they protect both personnel and equipment longevity.

Designing for Polyurethane Casting Applications

Designing for polyurethane casting requires a different mindset than designing for metal or injection-molded thermoplastics. When designing flexible polyurethane products, such as seals, gaskets, or soft-touch grips, the designer must account for the material’s elastomeric nature. Undercuts—features that would lock a rigid part into a mold—are often permissible because the flexible part can be stretched or deformed to be removed from the mold. However, designers must still consider the shore hardness; a tough rubber won’t stretch as much as a soft one. Wall thickness should be kept relatively uniform to ensure even curing, as thick sections can retain heat and cure at different rates than thin sections, leading to internal stresses or warping.

For rigid polyurethane applications, such as electronic housings or structural brackets, the design rules align more closely with those of traditional injection molding, yet offer distinct advantages. Rigid polyurethane can be cast with varying wall thicknesses more successfully than thermoplastics, allowing for the integration of thick mounting bosses and thin ribs in the same part without significant sink marks. Draft angles—the taper applied to vertical walls to aid part removal—are essential. Because polyurethane adheres strongly to mold surfaces, generous draft angles (usually 1-2 degrees or more) are recommended to reduce the force required to eject the part and prolong the mold life.

Specialty product design techniques often leverage the unique capabilities of casting. Overmolding is a common technique in which polyurethane is cast over a metal insert, such as a threaded bolt or a steel core, to combine the metal’s strength with the polymer’s surface properties. Designers must detail the interface between the insert and the polyurethane to ensure mechanical interlock or chemical bonding. Additionally, casting allows for the encapsulation of delicate electronics; the design must include stand-offs to position the circuit board at the center of the mold, allowing the resin to flow around it without displacing components.

Prototyping and testing are crucial phases in the design process. Because polyurethane casting uses lower-cost tooling (often silicone or soft aluminum) than steel injection molds, it is an ideal technology for iterative prototyping. Designers can produce a small batch of parts, test them under real-world conditions for impact resistance, chemical compatibility, or load-bearing capacity, and then quickly and affordably modify the mold or the design. This agility allows for rapid refinement of the product before committing to mass production, ensuring the final design is robust and fit for purpose.

Material Properties and Casting Challenges

The material properties of the polyurethane formulation directly dictate the casting parameters and the behavior of the final product. Factors such as pot life (the time the mixture remains liquid), viscosity, and demold time are inherent to the chemistry chosen. A material with high viscosity requires higher pressure to pump and may have difficulty filling thin mold sections, which may require larger gates or vacuum assistance. Conversely, a material with a very short pot life requires a machine capable of high flow rates to fill the mold before the material gels. Understanding the interplay between these chemical properties and the machine’s capabilities is essential for a smooth production run.

Common challenges in polyurethane casting often manifest as surface defects or structural inconsistencies. Air bubbles are the most common enemy; they can be caused by moisture contamination (which reacts with isocyanate to form CO2), turbulent pouring, or inadequate venting in the mold. Surface tackiness is another issue, often caused by improper mixing ratios, low mold temperatures, or inhibition by the mold surface itself. Shrinkage is also a factor; as polyurethane cures, it shrinks slightly. If this shrinkage is not accounted for correctly in the mold design, the final parts will be out of tolerance, potentially causing assembly issues downstream.

Solutions to these challenges involve a combination of process adjustment and chemical additives. To combat moisture bubbles, raw material tanks are often blanketed with dry nitrogen or equipped with desiccant breathers to keep atmospheric humidity out. Vacuum degassing the materials before casting is a standard solution for removing dissolved air. To address shrinkage, engineers often use “low-shrink” formulations or scale up the mold cavity slightly based on the material’s known shrinkage rate. For surface issues, adjusting the mold temperature or switching to a different release agent usually resolves the problem. Systematic troubleshooting involves isolating one variable at a time—temperature, ratio, or pressure—to identify the root cause of the defect.

Fine Details and Customization in Casting

One of the standout features of polyurethane casting is its ability to replicate wonderful details. Because the material enters the mold as a low-viscosity liquid, it can flow into microscopic crevices that high-viscosity injection molding plastics might bridge over. This capability allows for the reproduction of complex surface textures, such as leather grain, wood texture, or brushed metal finishes, directly from the mold surface. This level of fidelity is why polyurethane casting is frequently used for high-end prototypes and aesthetic parts where the look and feel must be indistinguishable from the final mass-produced item.

Customization is highly accessible in polyurethane casting due to the low cost of tooling. Industries such as medical devices or bespoke electronics often require short runs of parts tailored to specific user needs or equipment configurations. With casting, creating a new mold for a custom housing or a specifically sized grip is a fraction of the cost of cutting a steel tool. This economic advantage enables “mass customization,” in which a base product can be fitted with various custom polyurethane attachments or skins, produced in small batches without breaking the bank. Colors can also be easily customized by adding pigments directly into the machine’s mixing head, enabling color-matching to specific brand requirements.

Advanced machinery plays a pivotal role in enabling this level of detail and customization. Modern casting machines with precise flow control can perform “micro-casting” for tiny, intricate parts weighing only a few grams. Conversely, large displacement machines can fill massive molds for architectural details. Automation, such as multi-axis robotic pouring heads, allows the machine to follow complex mold contours, ensuring that the material is deposited precisely where needed to capture detail without trapping air. This synergy between advanced machine control and the natural flow properties of the resin enables manufacturers to push the boundaries of intricate, custom product design.

Joining Polyurethane Components

While casting allows for complex shapes, many products require assembling multiple polyurethane components or joining polyurethane to other materials. Adhesive bonding is the most common technique. Polyurethanes generally have high surface energy, making them receptive to bonding. Cyanoacrylates (super glue), epoxies, and structural polyurethane adhesives are frequently used. The key is surface preparation: abrading and cleaning the surface with a solvent ensures a strong chemical bond. For flexible foam parts, spray adhesives are often used to laminate foam layers together or to attach fabric, providing a bond that remains flexible and doesn’t crack when the part is compressed.

Mechanical joining methods offer a non-permanent alternative and are often designed into the casting itself. Inserts such as threaded brass nuts can be cast directly into the part (insert molding) or heat-staked in post-production, allowing the polyurethane part to be bolted to other components. Snap-fits can also be designed into rigid polyurethane parts, utilizing the material’s slight elasticity to lock parts together. However, designers must be careful with creep—the tendency of the material to deform under constant load—when designing snap-fits or bolted joints in softer polyurethanes. Washers are often recommended to distribute the load of a bolt head to prevent it from tearing through the material.

Innovative joining solutions continue to emerge. Some manufacturers use the “green strength” phase of curing to bond parts. By applying a second layer of polyurethane to a first layer that is still curing (but solid), the two layers can chemically cross-link at the interface, creating an inseparable monolithic part without the need for adhesives. This “overmolding” or “dual-shot” technique requires precise timing and machine control but results in a superior bond. Additionally, ultrasonic welding can be used with certain thermoplastic polyurethanes (TPUs), using high-frequency vibrations to melt the interface between two parts and instantly fuse them.

Stacking and Layering Polyurethane

Stacking and layering are techniques used to engineer composite properties that a single homogeneous cast cannot achieve. In structural applications, this might involve stacking layers of rigid polyurethane foam with differing densities. A high-density outer skin can provide impact resistance and durability, while a lower-density inner core reduces weight and cost. This sandwich construction is widely used to make lightweight yet strong panels for portable shelters or vehicle flooring. The layers are typically cast sequentially or bonded after curing to form a unified structural element that outperforms any single material.

Layering is also used to enhance specific performance properties, such as vibration damping or acoustic insulation. A manufacturer might cast a soft, viscoelastic polyurethane layer to absorb shock and vibration, with a harder, rigid polyurethane layer beneath for structural support. This is common in industrial wheels or engine mounts. The casting machine can be programmed to pour the first material, allow it to cure partially, and then immediately pour the second material on top. This sequential layering ensures a strong chemical bond between the strata, creating a multifunctional component in which each layer serves a distinct mechanical purpose.

Flexible Polyurethane and Living Hinges

The incredible flexibility of polyurethane formulations enables the creation of dynamic, moving parts from a single cast. Unlike rigid plastics that might snap under repeated bending, elastomeric polyurethanes can endure millions of flex cycles without failure. This durability makes them ideal for compliant mechanisms, bellows, and flexible couplings. The material’s resilience—its ability to return to its original shape after deformation—is a key property that engineers select for when designing parts that must bend, stretch, and recover repeatedly during their service life.

A living hinge is a design feature in which a thin, flexible web of material connects two rigid sections, allowing them to pivot relative to each other. While common in polypropylene injection molding, living hinges can also be successfully cast in polyurethane. The key is using a high-tear-strength, flexible formulation. The hinge area is designed to be thin enough to bend easily but thick enough to withstand tearing. During the casting process, the flow of material across the hinge area must be managed to align the polymer chains for maximum strength. These cast hinges eliminate the need for mechanical hardware such as pins and screws, simplifying assembly and reducing the part count.

Applications of flexible polyurethane extend far beyond simple hinges. They are used to create complex, monolithic protective cases that can be folded around a device. In robotics, flexible polyurethane skins are cast to cover moving joints, protecting internal mechanisms from dust while stretching and compressing with the robot’s movement. In the footwear industry, the midsole and outsole are often cast from flexible polyurethane to provide a combination of cushioning and durability that functions as a complex spring-and-hinge system for the foot. These applications showcase how the material’s inherent flexibility can be engineered into functional, moving geometry.

Related Technologies in Polyurethane Casting

Polyurethane casting does not exist in a vacuum; an ecosystem of related manufacturing technologies supports it. CNC (Computer Numerical Control) machining is perhaps the most closely linked. CNC machines are extensively used to machine master patterns and molds. A master pattern—a replica of the final part—is machined from tooling board or aluminum and then used to create silicone molds. For durable metal molds, CNC mills cut the negative cavity directly into blocks of aluminum or steel. CNC machining is also used post-casting to trim parts, drill precision holes, or face off surfaces to exact tolerances that casting alone cannot achieve.

3D printing (Additive Manufacturing) has revolutionized the prototyping phase of polyurethane casting. Instead of machining a master pattern, engineers can now 3D print the master using high-resolution SLA (Stereolithography) or PolyJet printers. This printed master is then used to make the silicone mold, drastically reducing lead times from weeks to days. Furthermore, 3D printing can produce complex mold cores or inserts that would be impossible to machine, which are then placed into the casting mold to create intricate internal geometries. This hybrid approach leverages the geometric freedom of 3D printing with the material performance of cast polyurethane.

Advancements in automation are transforming the casting floor. Robotic arms are increasingly integrated into casting machines to handle demolding, trim flash, and palletize finished parts. Automated guided vehicles (AGVs) transport molds through curing ovens and return them to the pouring station. This automation increases throughput, improves consistency, and reduces the manual labor required to handle heavy molds. Additionally, “smart” molds equipped with embedded sensors can communicate with the casting machine, triggering the pour only when the mold is at the exact right temperature and clamped pressure, further closing the loop on quality control.

Sustainability-focused technologies are also gaining traction. New bio-based polyols derived from soy, castor oil, or corn are being developed to reduce the petrochemical footprint of polyurethane parts. Casting machines are being adapted to handle these bio-resins without compromising performance. Furthermore, recycling technologies are improving; while thermoset polyurethanes are difficult to melt down, they can be ground into filler powder and reintroduced into new castings (“regrind”) or chemically recycled to recover raw materials. These advancements are helping the polyurethane casting industry move toward a more circular and environmentally responsible manufacturing model.

Resources for Polyurethane Casting

Equipment Manufacturers

- Hennecke: A global leader offering high-pressure and low-pressure metering machines for all PU applications.

- Cannon: Provides a vast array of dosing units, mixing heads, and turnkey plants for polyurethane processing.

- Graco: Known for durable pumping and dispensing equipment for industrial coatings and foams.

- RimCraft: Specializes in equipment for Reaction Injection Molding (RIM) and spray applications.

- Polytec EMC: Offers casting machines specifically designed for processing elastomer polyurethanes.

Software Providers

- Autodesk Moldflow: The industry standard for simulating plastic injection and compression molding, applicable to RIM processes.

- SolidWorks Plastics: A simulation tool integrated into SolidWorks CAD for predicting flow and potential defects.

- SigmaSOFT: A comprehensive virtual molding software that simulates the entire thermal and rheological casting process.

Training and Certification Programs

- Center for the Polyurethanes Industry (CPI): Offers technical conferences and educational resources on PU chemistry and safety.

- PMA (Polyurethane Manufacturers Association): Provides technical papers, regulatory updates, and training specifically for the cast elastomer industry.

- Underwriters Laboratories (UL): Offers certification and testing standards for polyurethane materials used in safety-critical applications.

Industry Associations and Forums

- Polyurethane Manufacturers Association (PMA): The premier organization for the cast polyurethane industry, facilitating networking and knowledge sharing.

- American Chemistry Council (ACC): Provides broad resources on plastics and polyurethanes, including health and safety guidelines.

- European Diisocyanate and Polyol Producers Association (ISOPA): A key resource for safety information and best practices in the European market.