Aerospace foam is a critical material found in many high-performance aerospace products. It consists of a lightweight polymer base filled with gas cells, making it ideal for applications where reducing weight while maintaining strength and performance is essential. In an industry driven by efficiency and safety, aerospace foam has become the material of choice for insulation, cushioning, and even structural components.

This material is used wherever durability and light weight are advantages, from commercial airliners and private jets to spacecraft and satellites. Its applications are rapidly expanding as the demand for lighter, more fuel-efficient, and comfortable aircraft grows.

The need for advanced foam materials is driving innovation across the aerospace sector. Are you interested in how aerospace foam helps create safer, more efficient aircraft, or in its role in improving the passenger experience? Learn more about the uses of this versatile material and how companies like Henghui are shaping the future of foam technology.

What is Aerospace Foam?

Aerospace foam is a specialized, lightweight material engineered from a polymer-based structure containing countless small, gas-filled cells. This cellular structure gives the foam its unique properties. By weight, aerospace foam offers exceptional strength and rigidity, making it a superior alternative to traditional materials in many applications.

Its primary characteristics are low density, high strength-to-weight ratio, and remarkable versatility. These qualities result from its composition and manufacturing process, which can be tailored to produce foams with specific properties such as thermal insulation, sound absorption, and fire resistance. The demand for such advanced materials is increasing as aerospace manufacturers seek to build lighter aircraft without compromising structural integrity or safety.

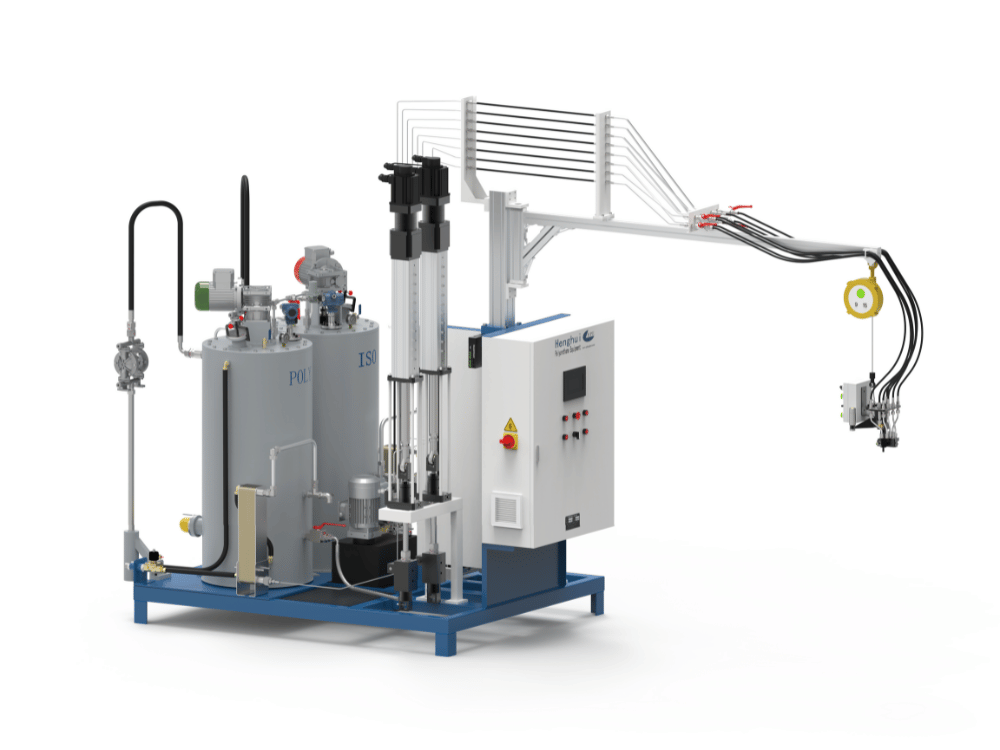

This growing demand highlights the importance of reliable manufacturing processes. Henghui specializes in producing high-quality polyurethane foaming machines that are crucial for creating these advanced materials. Our equipment ensures the precision and consistency required to meet the aerospace industry’s strict standards, playing a vital role in producing next-generation aircraft components.

How is Aerospace Foam Made?

The creation of aerospace foam, specifically polyurethane foam, begins with a precise chemical reaction. The process involves mixing two primary liquid components: polyols and isocyanates. When these are combined, they react to form a polymer, and a blowing agent simultaneously creates gas bubbles within the mixture. This reaction causes the material to expand and solidify into a cellular foam structure.

To achieve specific performance characteristics required for aerospace applications, various additives are introduced into the mixture. For instance, flame retardants are added to meet stringent fire safety standards, while other agents can enhance thermal resistance, UV stability, or energy absorption. The precise formulation is critical to the foam’s final properties.

This complex process is managed using sophisticated equipment. High- and low-pressure polyurethane foaming machines, such as Henghui’s PU Foaming Machine models, are essential for precisely controlling mixing ratios, temperature, and pressure. This precision ensures that every batch of aerospace foam has a consistent cell structure and uniform quality, which is paramount for its use in critical aerospace components.

How is Aerospace Foam Used?

Strands of aerospace foam are manufactured into sheets, blocks, or custom-molded shapes that are then integrated into various parts of an aircraft. The foam can be bonded to other materials, such as metal or composites, to create lightweight sandwich panels or used as a standalone component for insulation and cushioning. The process of shaping and applying the foam is tailored to the specific end-use.

The cured foam encapsulates countless gas pockets, creating a rigid yet lightweight matrix in the product’s desired shape. The combination of the polymer structure and the trapped gas gives the foam its hallmark properties: excellent thermal insulation, noise reduction, and energy absorption. These characteristics make it indispensable in modern aerospace design.

One of the most common applications is for thermal and acoustic insulation within the aircraft cabin and fuselage. Foam sheets are installed between the outer skin and the interior panels to maintain a comfortable cabin temperature and reduce engine and wind noise. For structural reinforcement, foam cores are used in panels for floors, galleys, and overhead bins, adding stiffness without significant weight. In seating, specialized energy-absorbing foams are used to enhance passenger comfort and safety during turbulence or hard landings, improving aircraft performance and the overall passenger experience.

The Evolution of Aerospace Foam

The story of aerospace foam begins in the mid-20th century, following the development of polyurethane polymers. Early applications were rudimentary, focusing on basic insulation and cushioning in military and commercial aircraft. The initial foams were functional but lacked the advanced properties of today’s materials.

The use of foam as a key aerospace component began to take shape in the 1960s. As aircraft started flying at higher altitudes and speeds, the need for better thermal and acoustic insulation became apparent. This spurred research into creating more effective and durable foam materials. Early foam technologies were adapted and refined, marking the first significant adoption of specialized foams in aircraft design.

In the 1970s, the oil crisis pushed the aerospace industry to prioritize fuel efficiency. This created a race to lighten aircraft, and foam’s high strength-to-weight ratio made it an attractive material. Engineers began documenting and refining its applications, moving beyond simple insulation to use it in semi-structural components. Because aerospace-grade foam was costly, its use was initially limited to applications where performance gains justified the expense.

By the 1980s, advancements in polymer chemistry led to the development of high-performance foams with enhanced fire resistance and durability. These materials started appearing in passenger cabin interiors, from seating cushions to side panels. Simultaneously, the manufacturing technology for creating these foams, including the development of more precise Polyurethane Foaming Machine systems, was advancing, enabling greater consistency and quality.

In the 1990s, the adoption of aerospace foam grew as manufacturing costs decreased and quality improved. This led to broader applications, including its use as a core material in composite sandwich structures for wings, control surfaces, and fuselage sections, further reducing aircraft weight.

Aerospace foam became a mainstream material by the 2000s. It was no longer just an accessory material but a critical component in the design of modern aircraft such as the Boeing 787 and the Airbus A350. Over the next two decades, foam technology continued to evolve, with a greater focus on sustainability and recyclability, and the development of more advanced properties to meet the demands of next-generation aircraft.

Some Really Cool Applications of Aerospace Foam

Today, new applications for aerospace foam appear regularly. While once considered a specialized material, you can now find it in a huge range of innovative uses across the industry:

Thermal Insulation

Advanced foams provide superior thermal insulation, significantly improving energy efficiency in aircraft. By minimizing heat transfer, these foams help maintain stable cabin temperatures, reducing reliance on the aircraft’s climate control systems. This reduces fuel burn and enhances passenger comfort during long-haul flights through extreme temperature variations.

Noise Reduction

The unique open or closed-cell structure of aerospace foam makes it an excellent material for sound absorption. It is used extensively in cabin walls, floors, and ceilings to dampen engine noise and aerodynamic sounds. This creates a much quieter cabin environment, enhancing the premium passenger experience and reducing travel fatigue.

Crash Protection

Specialized energy-absorbing foams are a critical safety feature. Used in aircraft seats, cabin interiors, and even in certain structural areas, these foams are designed to compress and absorb impact forces during an emergency landing or severe turbulence. This technology plays a vital role in protecting passengers and crew from injury.

Lightweight Panels

Aerospace foam is a core component in lightweight composite panels used for flooring, galleys, storage bins, and dividers. These panels offer incredible strength and rigidity at a fraction of the weight of traditional materials. This “lightweighting” is a primary goal in modern aircraft design, directly contributing to better fuel efficiency and reduced environmental impact.

The Future of Aerospace Foam

The future of aerospace foam materials is bright, with new advancements and applications continuously emerging. As manufacturing techniques become more sophisticated, the use of foam as a structural and functional material will only increase. With this growth, the aerospace industry needs skilled technicians who understand both the materials and the manufacturing processes powered by advanced machinery. Are you interested in this expanding world? Quality production starts with quality equipment, and Henghui is at the forefront of this technology.

Henghui is dedicated to empowering the makers and builders who will shape the future of aerospace. Our innovative PU Foaming Machine and Polyurethane Foaming Machine technology enable manufacturers to produce high-quality, consistent foam for a range of industries, from aerospace and automotive to construction and consumer goods.

With decades of experience and a passion for innovation, Henghui provides the state-of-the-art equipment needed to turn advanced materials into reality. Our machines offer the precision, reliability, and control necessary to meet the demanding standards of the aerospace industry and beyond. The need for advanced foam components has never been greater. Get started by contacting our team with any questions about our foaming solutions.