The march toward optimizing industrial production offers manufacturers many options, but it also makes selecting the best equipment for their facility a bit more complex. Where a production manager may have once decided simply based on available floor space, now there’s the added consideration of mixing technology, pressure levels, and material efficiency.

Two such industrial options—high-pressure and low-pressure polyurethane foaming machines—share many functions but are suited to very different uses and budgets. Polyurethane foaming machines play a critical role in creating everything from insulation to automotive seating. However, the mechanism by which they mix and dispense foam varies significantly. Understanding the differences, specifically the pros and cons of each, can help you make the choice that’s best for your manufacturing needs.

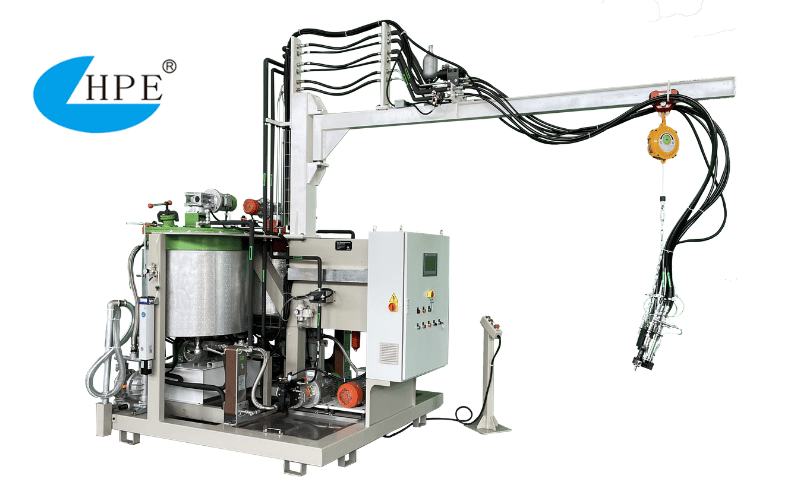

High-Pressure Polyurethane Foaming Machines Explained

While many machines handle chemical mixing, high-pressure foaming machines go further, using impingement mixing technology that forces chemicals together at extreme pressures to create a seamless blend. Sometimes referred to as reaction injection molding (RIM) equipment, they rely on high-velocity streams of polyol and isocyanate colliding in a small mixing chamber. This method ensures that the mixture is self-cleaning and highly uniform before it is dispensed into a mold or onto a surface. This precise, high-energy mixing process is the industry standard for large-scale operations where speed and quality are non-negotiable.

The main advantage of a high-pressure machine is the superior quality and consistency of the foam produced. Because the materials are mixed so thoroughly and quickly, the foam’s cellular structure is often better, resulting in a higher-performance end product. Furthermore, these machines are incredibly efficient. They are generally self-cleaning, meaning no solvents are required to flush the mixing head between shots, which drastically reduces chemical waste and environmental impact. In high-volume production lines, cycle times are significantly shorter, allowing manufacturers to produce more units per hour than with alternative methods.

That said, high-pressure technology comes with a steep entry price. The sophisticated pumps, mixing heads, and control systems required to handle such high pressures substantially increase the initial investment cost. Additionally, the equipment is complex and requires skilled technicians for operation and maintenance. If a breakdown occurs, repairs can be costly and technically demanding. This complexity makes high-pressure machines less suitable for small start-ups or low-budget projects where capital is tight. However, for established manufacturers, the long-term savings in material and labor often justify the upfront expense.

Low-Pressure Polyurethane Foaming Machines Explained

Low-pressure machines are sometimes thought of as the workhorses of the industry, using mechanical mixing to blend components at much lower speeds. In these systems, the polyol and isocyanate flow into a larger mixing chamber where a rotating agitator mechanically stirs them together. Once mixed, the foam is poured into the mold. This process is far gentler and relies on simple mechanical action rather than high-velocity collision, making it a distinct alternative for specific manufacturing scenarios.

The primary benefit of low-pressure equipment is its simplicity and affordability. The initial cost is significantly lower than that of high-pressure counterparts, making it an attractive option for small to medium-sized businesses or those just entering the polyurethane market. Because the operating pressures are lower, the machinery is less complex, easier to maintain, and presents a lower technical barrier for operators. This flexibility is excellent for small-batch production, discontinuous molding, or applications where the highest possible cycle speed isn’t critical. It allows manufacturers to experiment with different formulations without risking damage to expensive high-pressure components.

However, low-pressure mixing has its downsides. The most significant need is for a solvent flush cycle. After each pour, the mixing chamber must be cleaned with a solvent to prevent foam from hardening inside, which would increase material waste and ongoing disposal costs. Additionally, the foam quality, while generally good, may lack the absolute uniformity found in high-pressure mixes. For high-precision or mass-production needs, the slower cycle times and solvent waste can become limiting factors that drive up long-term operational costs despite the lower initial price tag.

Deciding Between High-Pressure and Low-Pressure Machines

Low-pressure machines are a great transitional option for those interested in polyurethane manufacturing but not yet ready to make a major capital investment. They let you enter the market, produce viable products, and learn the chemistry without the pressure of managing a complex, high-velocity system. If you are running a small workshop, prototyping new parts, or producing low volumes where cycle time isn’t critical, a low-pressure machine will give you the flexibility you need while keeping your startup costs manageable.

When you’re ready to scale up to industrial-level production, high-pressure machines provide the efficiency and quality necessary for mass manufacturing. They are ideal for applications requiring precision, speed, and minimal waste. While the choice can be overwhelming, considering factors such as your budget, anticipated production volume, and available technical expertise will help clarify the decision. Ultimately, both machine types have their strengths, and the right choice depends entirely on matching the equipment’s capabilities to your specific production goals.

Conclusion

To recap, high-pressure machines offer speed and quality for large-scale operations, while low-pressure machines provide an affordable entry point for smaller batches. The “best” machine isn’t a universal standard; it is the one that aligns with your specific budget and production requirements. By weighing the pros and cons carefully, you can confidently choose the equipment that best fits your manufacturing goals.