Automobile Interior Foaming Production Line

Auto Interior Foaming Producing Solutions

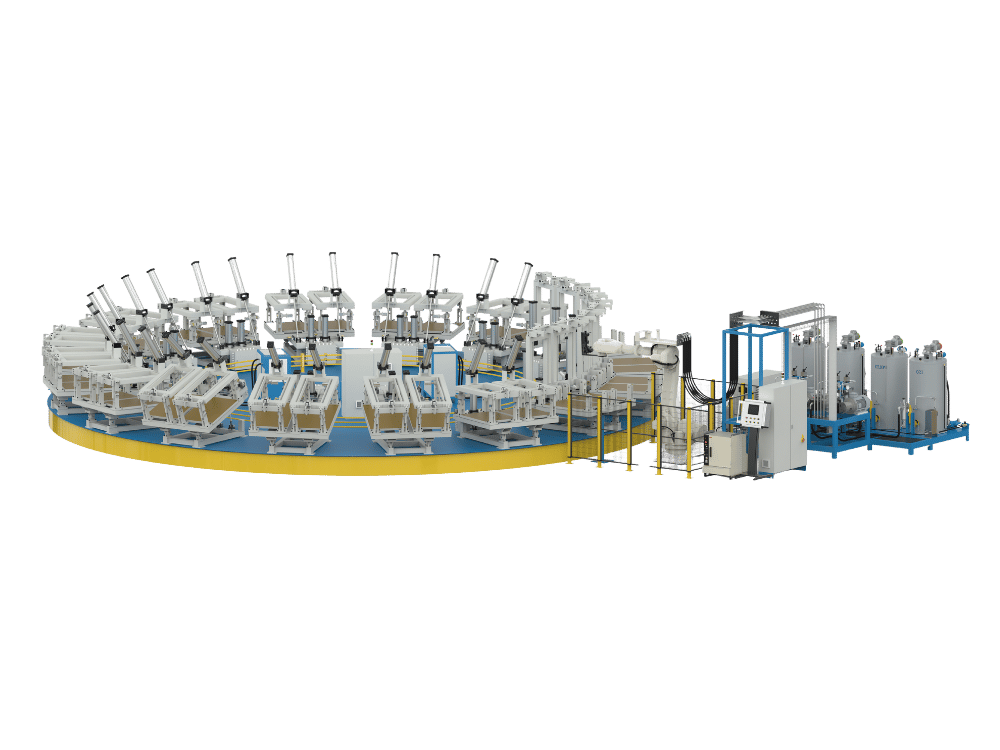

Our Automotive Interior Foaming Production Line is a state-of-the-art system designed for the efficient production of automotive seats and interior components. Featuring a horizontal circular turntable driven by a motor, the system integrates hydraulic or pneumatic mold bases for automatic mold opening and closing. With robotic automatic pouring, this production line ensures precision, consistency, and high-quality results.

Trustworthy Manufacturer of Polyurethane Equipment in China

Founded in 1999, Zhejiang Henghui Machinery Co., Ltd. is a leading manufacturer of polyurethane equipment. With ISO 9001:2000 certification since 2003, we produce over 100 sets of polyurethane equipment annually, with more than 2,500 systems operating worldwide. Our team of experienced engineers is dedicated to delivering innovative and reliable solutions tailored to your production needs.

Contact Us Now

Enter your inquiry details, We will reply you in 6 hours.

Advanced Interior Foaming Solution

The Automobile Interior Foaming Production Line is an innovative system that satisfies the requirements of the precise and efficient manufacture of automobile seats and interior parts. The system consists of a motorized horizontal circular turntable with hydraulic or pneumatic mold bases that can automatically open and close.

This production line improves the quality of the foam and reduces waste. The design versatility of this production line makes it the choice for manufacturers requiring dependable production of automotive interior components.

How It Works:

A motor-driven horizontal circular turntable guarantees the production line functionality. Hydraulic or pneumatic mold bases mounted on the turntable facilitate the automation of mold opening and closing. Foam pouring into the molds is automated using robotic arms. They ensure the deposition of the foam at the required volume and produce a uniform-density foam.

The turntable design enables uninterrupted production by allowing several molds to be used concurrently. This design feature reduces production line idle time and ensures that production requirements of medium and high volumes are achieved.

Key Features and Benefits:

Unlike traditional systems that rely on manual processes or less efficient designs, this production line integrates advanced automation and precision engineering to deliver superior performance. This design offers several key advantages:

Horizontal Circular Turntable

Ensures smooth and efficient mold rotation for continuous production, minimizing downtime.

Hydraulic/Pneumatic Mold Bases

Enables automatic mold opening and closing, significantly reducing manual intervention and improving operational efficiency.

Robotic Automatic Pouring

Delivers precise material distribution, ensuring consistent foam quality and reducing material waste.

Scalable Design

Supports multiple molds, making it ideal for medium- to high-volume production.

Enhanced Efficiency

Optimizes production speed while minimizing material waste, resulting in cost-effective operations.

Customizable Configurations

The system can be tailored to specific production needs, including mold sizes, pouring parameters, and automation levels, ensuring flexibility for diverse manufacturing requirements.

Characteristics:

- Horizontal circular turntable ensures smooth and efficient mold rotation.

- Hydraulic/pneumatic mold bases enable automatic mold opening and closing.

- Robotic automatic pouring ensures precise material distribution and consistent foam quality.

- Scalable design supports multiple molds for medium to high-volume production.

- Advanced automation reduces manual intervention and improves operational efficiency.

- Customizable configurations to meet diverse production requirements.

Application

Automotive: Seats, interior panels, armrests, and headrests.

Industrial Components: Precision-molded polyurethane parts requiring consistent quality and durability.

Why Choose This Production Line?

Perhaps The Most Advanced Production Line Automation Furniture Foaming Production Line is characterized by high automation, precision engineering, and a modular, scalable configuration. It suits all manufacturers who want to improve production efficiency and gain benefits from the production of automotive interior parts.