Automobile Steering Wheel Foaming Production Line

Providing Reliable Steering Wheel Foaming Solutions

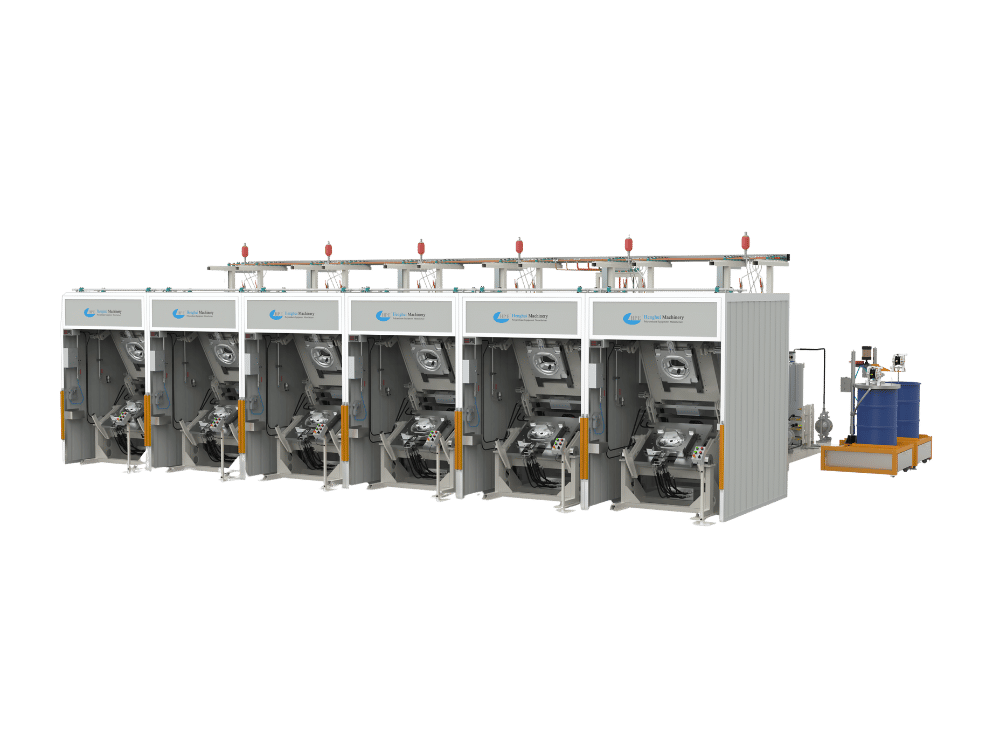

With the integration of high-pressure foaming machines and hydraulic molds, our automotive steering wheel foaming production line is configured into 4-station and 6-station systems. Each station can also be equipped with an individual injection nozzle for standalone color customization, enabling the production line to fulfill varying production criteria. Our automotive steering wheel foaming production line is configured to improve production efficiency and accuracy.

Most Reliable Manufacturer of Polyurethane Equipment in China

Having been established in 1999, Zhejiang Henghui Machinery Co., Ltd. is recognized as the first company in China to produce Polyurethane Equipment. We received ISO 9001:2000 certification in 2003 and, as of today, we manufacture and sell more than 100 sets of Polyurethane Equipment each year. More than 2,500 sets are operational worldwide. With an expert engineering team, we guarantee practical, dependable solutions that meet the client’s specifications.

Contact Us Now

Enter your inquiry details, We will reply you in 6 hours.

Advanced Steering Wheel Foaming Solution

The Automobile Steering Wheel Foaming Production Line is the best of the best, adding value with high precision and efficient output. The Fully Integrated Automotive Steering Wheel Foaming Production Line, featuring high-pressure foaming machines and hydraulic molds, is configurable as a 4- or 6-station line with flexible production scalability.

For even greater efficiency, each should have a unique injection nozzle. Such nozzles enable independent color injection for foams, allowing for the production of multi-color and design foams with no compromise to quality and production efficiency.

How the System Works

The fully automated production line consists of high-pressure foaming machines integrated with hydraulic molds. Raw materials are preloaded into tanks and accurately weighed using high-pressure pumps. The materials are injected into the molds through dedicated nozzles that can color according to the customer’s design.

The hydraulic molds produce consistent, high-quality parts, and the multi-station configuration allows parallel production across the different workstations, creating an efficient system. The entire operation is automated, eliminating manual work.

Key Features and Benefits:

Unlike traditional low-pressure foaming systems, this production line utilizes high-pressure foaming technology integrated with hydraulic molds, ensuring superior precision and efficiency. This design offers several key advantages:

High-Pressure Foaming Technology

Ensures precise mixing and consistent foam quality for superior steering wheel production.

Configurable Multi-Station Setup

Available in 4-station or 6-station configurations to meet varying production needs, enhancing scalability.

Independent Injection Nozzles

Each station features a dedicated nozzle for independent color addition, increasing flexibility and efficiency.

Hydraulic Mold Integration

Provides reliable and consistent mold performance, ensuring high-quality results.

Scalable and Efficient Design

Ideal for both medium- and high-volume production, optimizing operational efficiency.

Automated Process Control

Equipped with PLC automation, the system ensures precise control over every step, from material injection to mold curing, reducing manual intervention and improving production consistency.

Characteristics:

- High-pressure foaming technology ensures precise mixing and consistent foam quality.

- Configurable 4-station or 6-station setups for flexible production scalability.

- Independent injection nozzles at each station allow for efficient color addition.

- Hydraulic mold integration ensures reliable and consistent mold performance.

- PLC automation for precise process control, reducing manual intervention.

- Scalable design suitable for medium to high-volume production requirements.

Application

Automotive: Steering wheels with customizable colors and high-quality foam finishes.

Industrial Components: Precision-molded polyurethane parts requiring consistent quality and durability.

Why Choose This Production Line?

Automobile Steering Wheel Foaming Is The Best Production Selection Because Of Its Technology, Flexible Configurations, And Repeatable Accuracy. The Production Equipment Gives Manufacturers the Opportunity to Increase Production Efficiency While Meeting the Varied Production Needs of the Automotive Sector.