Discover how PU foaming machines work, explore the surging polyurethane market, and learn why these machines are essential investments for modern manufacturing.

In today’s competitive industrial landscape, polyurethane (PU) foaming technology is experiencing remarkable growth. Among the various manufacturing equipment available, PU foaming machines stand out for their critical role in producing everything from automotive seating and insulation panels to memory foam mattresses and shoe soles. These versatile machines have become the backbone of production lines in the automotive, furniture, construction, and footwear industries. By enabling manufacturers to create products with precise density, flexibility, and durability, they have become indispensable tools for efficient and high-quality production.

Whether your focus is on producing comfortable furniture or energy-efficient building materials, PU foaming machines offer scalable, high-precision solutions that drive manufacturing success. More importantly, they represent a highly profitable capital investment with growing global demand. They provide businesses with opportunities to optimize production costs, improve product quality, and expand into new market segments. In this comprehensive guide, you’ll learn what PU foaming is, how the machines work, and the key factors that make them a vital asset for any production facility.

What Is PU Foaming?

PU foaming, or Polyurethane foaming, is a chemical process used to create durable, lightweight, and versatile foam materials. It is widely used across industries, from automotive to construction, to create products that require specific cushioning, insulation, or structural properties. Whether you are sitting on a car seat, walking in running shoes, or insulating a home against the cold, you are likely benefiting from the results of PU foaming technology.

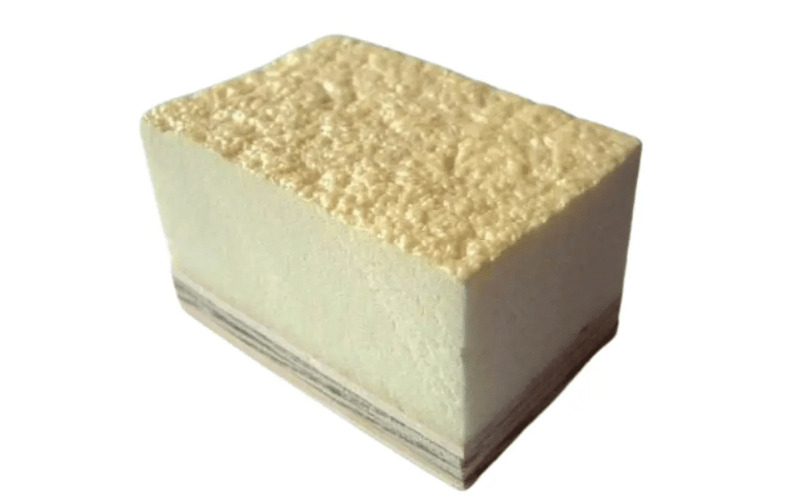

The process involves reacting two main liquid chemical components: a polyol and an isocyanate. When these two components are mixed together in precise ratios, a rapid exothermic chemical reaction occurs. This reaction causes the mixture to expand and cure, transforming from a liquid to a solid cellular foam. Depending on the specific formulation of the chemicals and the additives used, the resulting foam can be engineered to be soft and flexible, tough and rigid, or somewhere in between.

Polyurethane foam is incredibly versatile, which is why it is categorized into different types based on its physical properties. The most common types include flexible foam, used primarily for comfort applications such as bedding and upholstery; rigid foam, used for thermal insulation in refrigerators and buildings because of its low thermal conductivity; and integral skin foam, which forms a tough outer skin for products such as steering wheels and armrests. This versatility not only makes PU foaming essential for product innovation but also offers significant environmental and economic benefits, such as energy savings from improved insulation and waste reduction through precise molding.

Key Differences Between PU Foaming Machines

When selecting a PU foaming machine, the primary distinction lies between High-Pressure and Low-Pressure technologies. Understanding the differences between these two types is crucial for optimizing production efficiency and cost.

High-Pressure vs. Low-Pressure Machines

| Feature | High-Pressure Foaming Machine | Low-Pressure Foaming Machine |

|---|---|---|

| Mixing Method | Impingement mixing (high velocity collision of streams). | Mechanical mixing (using a motorized stirrer/mixer). |

| Cleaning | Self-cleaning; no solvent required. | Requires solvent (usually methylene chloride) to clean the mixing head. |

| Material Waste | Minimal waste due to precise start/stop. | Higher material waste due to solvent flushing cycles. |

| Maintenance | Lower daily maintenance; more complex periodic service. | Higher daily maintenance (cleaning mixer); simpler mechanics. |

| Cost | Higher initial investment cost. | Lower initial investment cost. |

| Production Speed | Faster cycle times; ideal for high-volume automated lines. | Slower cycle times; suitable for smaller batches or complex molds. |

| Foam Quality | Superior mixing quality and uniform cell structure. | Good mixing quality, though slightly less uniform than high pressure. |

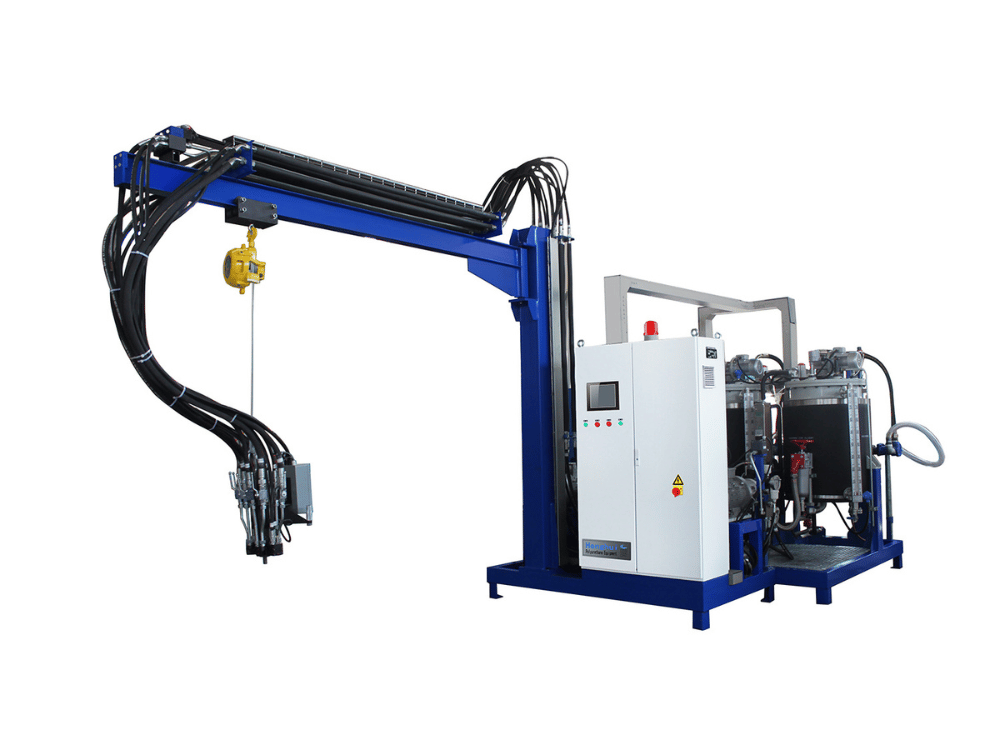

High-Pressure Machines: These are the industry standard for large-scale, automated production. They utilize high-velocity pumps to force chemicals into a mixing chamber where they collide and mix instantly. The major advantage is that the mixing head is self-cleaning, often using a mechanical piston to dislodge residual material, eliminating the need for chemical solvents. This makes them more eco-friendly and efficient for continuous operation.

Low-Pressure Machines: These machines use a mechanical stirrer in the mixing head to blend the components. While the initial equipment cost is significantly lower, they require a solvent-flushing cycle after each pour to clean the mixing chamber. This results in ongoing solvent costs and hazardous waste disposal. However, they are often preferred for specialized applications where flow rates need to be very low or for smaller operations with budget constraints.

Manual vs. Automated Systems: Beyond pressure types, machines can be manual or fully automated. Automated lines, often integrating robotics, offer higher precision and throughput but come with a higher price tag. Manual machines provide flexibility for custom jobs but rely heavily on operator skill.

How PU Foaming Machines Work

Over the past few decades, the technology behind PU foaming machines has evolved from simple manual mixing to sophisticated, computer-controlled systems. This evolution has allowed for the seamless integration of foaming stations into complex manufacturing assembly lines.

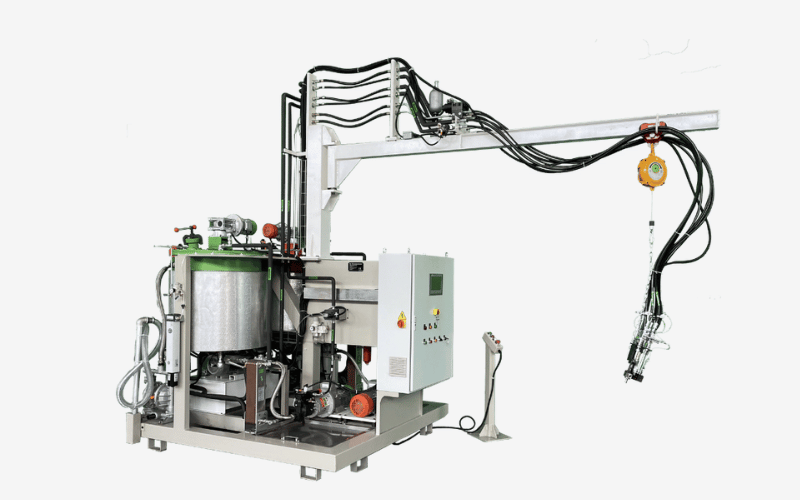

A PU foaming machine functions as a precise dosing and mixing unit. The core of the machine consists of two (or more) storage tanks that hold the raw chemical components—polyol and isocyanate. These tanks are equipped with temperature control systems to ensure the chemicals remain at the optimal viscosity for processing. From the tanks, high-precision metering pumps draw the chemicals and deliver them to the mixing head. The accuracy of these pumps is critical, as even a slight deviation in the chemical ratio can ruin the final foam product.

The mixing head is the “heart” of the machine. In a high-pressure system, the chemicals are injected into a small mixing chamber at varying pressures (often exceeding 150 bar). The streams collide at high speeds, creating a turbulent mixture that is immediately dispensed into a mold or onto a conveyor. Once the pour is complete, a hydraulic piston instantly cleans the chamber, preparing it for the next shot. In low-pressure systems, the chemicals enter a larger chamber where a rotating agitator blends them before dispensing.

Modern machines heavily rely on automation and PLCs (Programmable Logic Controllers). Operators can set specific “recipes” or pouring programs via a touchscreen interface. These programs control the exact weight of the pour, the component ratios, and the flow rate. Advanced machines also feature closed-loop flow monitoring that constantly adjusts pump speed to maintain accuracy in real time. This level of precision ensures that every product, whether it’s a car seat or an insulation panel, is identical in weight and quality.

Top Features of PU Foaming Machines

Modern PU foaming machines are equipped with advanced features that enhance efficiency, safety, and product quality. These features allow manufacturers to meet stringent industry standards while minimizing downtime.

- High-Precision Metering Pumps: The accuracy of the chemical mix dictates the quality of the foam. Top-tier machines use axial piston or magnetic-drive pumps to ensure consistent flow rates and precise ratio control, often within ±0.5% tolerance. This ensures uniform foam density and structural integrity.

- Intelligent Temperature Control Systems: Chemical viscosity changes with temperature, affecting mixing quality. Advanced machines feature integrated heating and cooling units (chillers) for the component tanks and hoses. This maintains the chemicals at the exact processing temperature required for the specific formulation, regardless of external environmental conditions.

- Automated Mixing Head with Self-Cleaning: For high-pressure machines, this feature is a standout. It eliminates the need for solvent flushing, reducing operational costs and environmental impact. The design often allows for “L-style” or straight-style injection, providing flexibility for different mold orientations.

- User-Friendly PLC Interfaces: Modern Human-Machine Interfaces (HMIs) allow operators to easily store and recall hundreds of pouring programs. These touchscreens provide real-time visualization of pressure, temperature, and flow data, along with diagnostic tools and alarm logs to troubleshoot issues quickly.

- Eco-Friendly Design and Energy Efficiency: Leading manufacturers are designing machines compatible with eco-friendly blowing agents (like Pentane or water-blown systems) to meet environmental regulations. Additionally, variable-frequency drives (VFDs) on motors help reduce energy consumption during idle periods.

- Safety Interlocks and Monitoring: Handling isocyanates requires strict safety protocols. Machines are equipped with leak-detection sensors, overpressure alarms, and emergency shutoff switches. Ventilation integration features also ensure that any fumes generated during the process are safely extracted from the workspace.

PU Foaming Machine Market Trends

As industries strive for lighter, more energy-efficient, and comfortable products, the market for PU foaming machines is witnessing significant evolution. The integration of Industry 4.0 technologies is transforming these machines from standalone units into connected, smart manufacturing hubs.

Growing Demand in Key Industries

The automotive sector remains a primary driver, with a push towards lightweight electric vehicles (EVs) increasing the demand for high-quality PU foam for seating and acoustic insulation. Simultaneously, the construction industry’s focus on green buildings is fueling the demand for rigid PU foam panels for superior thermal insulation. The furniture and bedding markets continue to expand, driven by consumer demand for premium comfort products such as memory foam mattresses.

Technological Advancements and Automation

There is a clear trend toward fully automated production lines. Manufacturers are increasingly integrating PU foaming machines with robotic pouring arms and automated mold carriers (carousels). This reduces labor costs and removes human error from the pouring process. Furthermore, the adoption of IoT (Internet of Things) enables remote monitoring and predictive maintenance, allowing the machine to alert operators to potential pump failures before they cause downtime.

Sustainability and Customization

Environmental regulations are pushing the market toward machines capable of processing bio-based polyols and low-GWP (Global Warming Potential) blowing agents. Additionally, there is a trend toward modular machine designs that allow manufacturers to easily upgrade or customize their equipment as their production needs change, offering flexibility in a dynamic market.

Why Selling PU Foaming Machines Is a Good Business?

The manufacturing equipment sector offers robust opportunities, and PU foaming machines are particularly positioned for high profitability and long-term growth. As a B2B product, they serve essential industries unlikely to experience a decline in demand.

High Demand and Profitability

The ubiquity of polyurethane products means that the machinery required to produce them is in constant demand. From developing nations building their infrastructure (requiring insulation) to developed markets demanding luxury automobiles and furniture, the customer base is vast. These machines are high-ticket capital equipment that allow for healthy profit margins for distributors and manufacturers like Henghui.

Opportunities for Customization and Differentiation

Unlike generic consumer electronics, PU foaming machines often require customization to fit specific production lines. This allows sellers to offer value-added engineering services. By providing tailored solutions—such as specific tank sizes, mixing head configurations, or automation integration—businesses can differentiate themselves from competitors and command higher prices.

Recurring Revenue and Long-Term Relationships

Selling the machine is just the beginning. These machines require regular maintenance, spare parts (seals, filters, sensors), and occasional upgrades. This creates a steady stream of recurring revenue. Furthermore, establishing a relationship as a trusted machinery provider often leads to repeat sales as the customer expands their production capacity.

Sustainability as a Growth Driver

With the global push for energy efficiency, the demand for insulation materials is skyrocketing. Selling machines that produce high-performance insulation positions a business at the forefront of the green revolution. This alignment with global sustainability trends ensures long-term market relevance and growth potential.

Factors Affecting PU Foaming Machine Performance

Achieving the perfect foam product requires more than just buying a good machine; it requires managing several variables that influence performance. Reliable production depends on controlling these factors meticulously:

- Quality of Raw Materials: The purity and stability of the polyol and isocyanate are paramount. Contaminants or moisture in the chemicals can lead to poor cell structure or collapsed foam. Ensuring materials are stored correctly and are within their shelf life is the first step to quality.

- Temperature Control: As mentioned, chemical viscosity is temperature-dependent. If the chemicals are too cold, they won’t mix properly; if they are too hot, the reaction may happen too fast (premature curing). Consistent temperature management throughout the tank and hose system is vital for repeatability.

- Machine Calibration and Ratio Accuracy: The stoichiometric ratio of the two components must be precise. If the machine delivers too much isocyanate, the foam will be brittle; too much polyol, and it will be soft and sticky. Regular calibration of the metering pumps and flow meters is essential to maintain this balance.

- Mixing Head Cleanliness and Condition: The mixing head is where the magic happens. Worn-out injectors or residue buildup in the chamber can disrupt the mixing turbulence, leading to streaks or voids in the foam. Regular inspection and maintenance of the mixing head seals and pistons are critical.

- Operator Expertise: Even the most advanced automated machine requires a skilled operator. Understanding how to adjust parameters for changes in humidity, mold temperature variations, and different foam formulations is key to avoiding defects. Proper training ensures the machine is used to its full potential.

Conclusion

From enabling the mass production of comfortable car seats to creating energy-saving insulation for skyscrapers, PU foaming machines are the unsung heroes of modern manufacturing. These sophisticated devices not only meet the diverse demands of various industries but also create significant opportunities for business expansion and profitability.

As the market continues to grow, driven by trends in automation and sustainability, businesses have a golden opportunity to invest in or distribute this technology. By understanding the mechanics, types, and critical features of PU foaming machines, manufacturers can optimize their production lines, while distributors can capitalize on a high-demand market. Whether you are looking to upgrade your factory floor or expand your product catalog with Henghui machinery, harnessing the power of PU foaming technology is a strategic move toward a more efficient and profitable future.