Polyurethane foam, commonly known as PU foam, is a remarkably versatile polymer that has quietly integrated itself into nearly every aspect of modern life. From the comfortable sofa in your living room and the insulation in your walls to the dashboard of your car and the protective packaging securing your electronics, PU foam is an unsung hero of manufacturing. Its combination of lightweight, durability, and high moldability makes it an exceptionally cost-effective and scalable solution for countless industries, enabling the creation of high-performing, affordable products.

While its benefits are vast, the story of polyurethane foam is not without its complexities. As global awareness shifts toward sustainability, the environmental challenges associated with PU foam, such as its reliance on fossil fuels, limited biodegradability, and the development of recycling infrastructure, have come into focus. This comprehensive guide will explore the world of PU foam in its entirety. We will delve into its chemical makeup, manufacturing processes, diverse properties, and wide-ranging applications. We will also address the challenges and disadvantages associated with its production and use, providing a balanced and thorough understanding of this ubiquitous material.

What is Polyurethane Foam (PU Foam)?

Polyurethane foam is a synthetic polymer created through a chemical reaction between two primary types of liquid chemicals: polyols and diisocyanates. When these components are mixed, typically with catalysts and blowing agents, they undergo an exothermic reaction that produces the polyurethane polymer. This reaction simultaneously generates a gas (such as carbon dioxide or another blowing agent) that is trapped within the polymer matrix, creating a cellular structure. The result is a foam that can be engineered to be either flexible and soft or rigid and stiff, depending on the specific chemicals and additives used in the formulation.

The chemical composition of PU foam is what gives it its unique properties. The polymer backbone consists of urethane linkages (-NH-(C=O)-O-), which are formed during the reaction. The choice of polyol largely determines whether the foam will be flexible or rigid. Long, flexible polyol chains result in a soft, open-cell foam ideal for cushioning. In contrast, shorter, more highly branched polyols create a firm, rigid, closed-cell foam perfect for insulation and structural applications. This adaptability is a key reason for its widespread use.

This structure is the foundation of PU foam’s lightweight yet durable nature. In rigid foams, the closed-cell structure traps an insulating gas, providing exceptional thermal resistance. These sealed cells also make the foam highly resistant to moisture absorption, preventing water from compromising its integrity or insulation value. In flexible foams, the open-cell structure allows air to move freely, which gives it its cushioning and breathability. This inherent resistance to moisture, many chemicals, and mechanical stress makes polyurethane foam a reliable and high-performing material for countless applications, from thermal insulation in extreme environments to long-lasting comfort in furniture and support in various industrial components.

How is Polyurethane Foam Made?

The manufacturing process of polyurethane foam is a precise exercise in chemical engineering, transforming liquid raw materials into a solid, cellular product with specific, tailored properties. The core of the process is the polymerization reaction between polyols and diisocyanates. These two main liquid components are stored in separate tanks and are precisely metered before being intensely mixed together in a mixing head.

Simultaneously, other crucial ingredients are added to the mix. Catalysts are introduced to control the reaction rate, ensuring the foam forms at the desired rate. Surfactants are used to stabilize the foam’s cellular structure, preventing the cells from collapsing before the polymer has cured. Most importantly, a blowing agent is added. In many formulations, water is used as a blowing agent; it reacts with the isocyanate to produce carbon dioxide, which expands the mixture and forms the foam’s cells. In other cases, physical blowing agents (low-boiling-point liquids) are used, which vaporize from the heat of the reaction, creating the cellular structure.

From the mixing head, the reacting liquid is dispensed. For slabstock foam, used for mattresses and furniture, the liquid is poured onto a moving conveyor belt where it rises freely into a large continuous block, or “bun.” This bun can be hundreds of feet long and is later cut into smaller blocks for storage and curing before being sliced into sheets of the desired thickness. For molded foam, common in automotive seating, the liquid mixture is injected directly into a closed mold. The foam expands to fill the mold’s cavity, taking on its exact shape.

One of the most significant advantages of this manufacturing process is the ability to control the foam’s final properties. By adjusting the type and ratio of polyols and isocyanates, manufacturers can control the foam’s rigidity. The amount and type of blowing agent determine the foam’s density. Additives can also be included to impart special characteristics, such as flame retardants for safety, pigments for color, or antimicrobial agents for medical applications. This incredible versatility allows PU foam to be produced in various forms—from large blocks and thin sheets to intricate molded shapes and even two-part liquid systems for spray-in-place insulation—making it one of the most adaptable materials in modern manufacturing.

What is the Full Form of Polyurethane Foam?

The complete form of the acronym PU foam is, quite simply, Polyurethane Foam. The name itself provides a clue to its chemical origins. It is derived from the polymerization process that creates urethane linkages between monomer units. A “poly” urethane is a material composed of many urethane chemical units, chained together to form a long polymer. This polymer forms the solid backbone of the foam material.

Polyurethane is classified as a thermosetting polymer. Unlike thermoplastics (like polyethylene or PVC), which can be melted and reformed multiple times, thermosets undergo an irreversible chemical change during curing. Once polyurethane foam has been created and set, it cannot be melted back into a liquid and reshaped. If it is heated to a high enough temperature, it will char and decompose rather than melt.

This thermosetting nature is a key reason for PU foam’s durability and stability across a wide range of temperatures. It contributes to its excellent performance in applications where structural integrity and heat resistance are essential, such as building insulation, automotive components, and industrial equipment. The widespread use of PU foam in manufacturing and construction is a direct result of the reliable, permanent properties established during its thermosetting polymerization.

What are the Main Challenges in Manufacturing PU Foam?

While polyurethane foam is a highly versatile and widely used material, its manufacturing process is not without significant challenges. These complexities can impact cost, quality, and environmental sustainability.

- Cost of Production: The manufacturing of PU foam is an energy-intensive process. The raw materials, primarily polyols and isocyanates, are derived from crude oil, making their prices subject to the fluctuations of the global petroleum market. The chemical reactions require precise temperature and pressure controls, which consume considerable energy. Furthermore, specialized machinery, such as high-pressure mixing heads, large-scale conveyor systems, and molding presses, represents a significant capital investment, adding to the overall cost of production.

- Environmental Impact: PU foam presents several environmental challenges. Its primary ingredients are fossil fuel-based, contributing to resource depletion. More significantly, the material is not readily biodegradable, leading to long-term waste accumulation in landfills. While recycling technologies exist, the infrastructure for collecting and processing post-consumer PU foam is still limited in many regions. Chemical recycling is energy-intensive, and mechanical recycling often yields lower-value products such as carpet underlay.

- Quality Control: Achieving consistent quality is a constant challenge in foam production. The final properties of the foam—such as density, cell structure, and firmness—are susceptible to slight variations in the chemical formulation, mixing ratios, temperature, and humidity. An improperly balanced reaction can lead to defects like voids, collapses, or inconsistent density throughout the foam block or molded part. This requires sophisticated monitoring and control systems to ensure every batch meets strict specifications.

- Health Concerns: The manufacturing process involves handling hazardous chemicals, particularly isocyanates. These compounds are potent respiratory and skin sensitizers. Inhalation of isocyanate vapors can cause severe asthma-like reactions in workers. Consequently, manufacturing facilities must implement stringent engineering controls, ventilation systems, and personal protective equipment (PPE) protocols to protect their workforce. Additionally, the off-gassing of volatile organic compounds (VOCs) during the curing process can contribute to air pollution and requires proper management.

- Flammability: Standard polyurethane foam is combustible. While flame-retardant additives can be used to meet fire safety standards, they can also pose environmental and health concerns. The foam’s flammability poses safety risks during production, storage, and final application if not correctly managed, requiring careful consideration in high-temperature environments or in applications subject to strict fire codes.

How Does Polyurethane Foam Affect Product Quality?

Polyurethane foam significantly enhances product quality across a multitude of applications, primarily through its unique combination of lightness, durability, and excellent insulating properties. The quality it imparts is directly tied to its engineered properties. For instance, in furniture and bedding, the high resilience of flexible PU foam provides lasting comfort and support. Its ability to retain shape under repeated stress means that a sofa cushion or mattress will resist sagging and “bottoming out” for many years, directly improving the product’s lifespan and user satisfaction.

In thermal applications, the quality contribution is even more pronounced. The closed-cell structure of rigid PU foam provides one of the highest R-values per inch among commercially available insulation materials. This superior thermal insulation enables manufacturers of refrigerators, freezers, and insulated panels to create highly energy-efficient products that reduce end-user operational costs. The foam’s resistance to moisture ensures this insulation value is not compromised over time by water absorption, a common failure point for other insulation types like fiberglass.

However, PU foam also has limitations that can affect product quality if not adequately accounted for. Its susceptibility to UV degradation is a notable issue. When exposed to direct sunlight, polyurethane foam will discolor, turning yellow, and its surface will become brittle and powdery over time. This means that for outdoor applications, the foam must be protected with a UV-resistant coating or covering to maintain its structural integrity. Additionally, some standard grades of PU foam can become brittle at very low temperatures, limiting specific cryogenic or polar applications. An understanding of these limitations is crucial for engineers and designers to ensure the foam is used in ways that maximize its benefits and mitigate its weaknesses.

What are the Advantages of Polyurethane Foam?

The widespread adoption of polyurethane foam across diverse industries is a testament to its numerous advantages. These benefits make it a superior choice for many applications compared to traditional materials.

- Cost-Effective: For the level of performance it delivers, PU foam is remarkably cost-effective. The raw materials are produced on a massive scale, and the manufacturing processes are highly efficient, enabling high volumes at a relatively low per-unit cost. This economic efficiency makes high-performance insulation and comfortable furniture accessible to a broader market.

- Versatile: This is perhaps PU foam’s most significant advantage. By simply altering its chemical formulation, it can be made soft and pliable for a mattress topper or hard and strong enough to support structural loads. It can be sprayed, poured, or molded into nearly any shape imaginable, giving designers and engineers immense freedom. This adaptability allows a single material family to serve applications in insulation, furniture, automotive, packaging, marine, and medical industries.

- Lightweight: Polyurethane foam has an excellent strength-to-weight ratio. This low density reduces the overall weight of final products, a significant benefit for transportation and construction. Lighter cars are more fuel-efficient, lighter furniture is easier to move, and lightweight insulation panels are easier and safer to install, reducing labor costs and structural load requirements.

- Thermal Insulation: Rigid, closed-cell polyurethane foam is one of the most effective thermal insulators commercially available. Its high R-value means that a thinner layer of PU foam can achieve the same level of insulation as a much thicker layer of other materials, such as fiberglass or mineral wool. This is critical in applications where space is limited, such as in refrigerators or building retrofits.

- Moisture Resistance: The closed-cell structure of rigid PU foam makes it inherently resistant to water and moisture vapor. It does not absorb water, which means it will not promote mold or mildew growth, and its thermal performance will not degrade in humid environments. This makes it an ideal choice for below-grade insulation, roofing, and in marine applications.

- Durability: Polyurethane foam is a durable, long-lasting material. It is resistant to chemical attack, does not rot or decay, and maintains its physical properties over a long service life. Flexible foams can withstand millions of compression cycles without losing support, and rigid foams provide stable, reliable insulation for the lifetime of a building.

What are the Disadvantages of Polyurethane Foam?

Despite its many advantages, polyurethane foam also has several notable disadvantages that must be considered by manufacturers and consumers alike. These drawbacks are primarily related to environmental impact, safety, and material limitations.

- Environmental Concerns: The most significant disadvantage of PU foam is its ecological footprint. It is derived from non-renewable petrochemicals. More importantly, it is not biodegradable, meaning it persists in landfills for centuries. While PU foam is technically recyclable, the infrastructure for collecting and reprocessing it is not widely available. Mechanical recycling often downcycles the material into lower-quality products, and while chemical recycling is promising, it remains an energy-intensive and costly process.

- Flammability: In its untreated form, polyurethane foam is flammable and can release toxic smoke containing compounds like carbon monoxide and hydrogen cyanide when it burns. Although fire retardants are added to most PU foam products to meet safety standards, the use of some of these chemical retardants has raised its own health and environmental concerns, with some being phased out due to their toxicity.

- Chemical Sensitivity: While resistant to many chemicals, PU foam is vulnerable to certain organic solvents, strong acids, and bases. Exposure to these substances can cause the foam to soften, swell, or dissolve completely, limiting its use in environments with aggressive chemical exposure.

- Health Risks: The manufacturing process involves isocyanates, which are potent respiratory sensitizers and can pose significant health risks to workers if not handled with extreme care. For consumers, the primary concern is the off-gassing of volatile organic compounds (VOCs) from new foam products, especially in enclosed spaces. While modern foams are often certified for low VOC emissions, this “new foam smell” can irritate sensitive individuals.

- UV Degradation: Polyurethane foam is not resistant to ultraviolet (UV) light. When exposed to sunlight, the foam will quickly yellow and the surface will become brittle and powdery. For any outdoor application, PU foam must be painted or covered with a UV-protective layer to prevent this degradation, which adds an extra step and cost to the installation.

What are the Properties of Polyurethane Foam?

The properties of polyurethane foam can be finely tuned during the manufacturing process, but a set of core characteristics defines its performance. These properties are what make it such a valuable material for a wide range of applications.

- Density: PU foam is available in a wide range of densities, from less than 1 pound per cubic foot (pcf) for super-soft, flexible foams to over 40 pcf for high-density rigid tooling boards. Density is a primary determinant of many other properties, including hardness, compressive strength, and cost. Generally, higher density equates to greater strength and durability.

- Rigidity/Flexibility: Polyurethane foams lie on a spectrum from extremely flexible to completely rigid. Flexible foams, characterized by their open-cell structure, are designed for cushioning and comfort, exhibiting high resilience and the ability to conform to shapes. Rigid foams, with their closed-cell structure, are designed for thermal insulation and structural support, offering high compressive strength and dimensional stability.

- Thermal Stability: PU foam performs well across a wide range of temperatures. Rigid foams maintain their structural integrity and insulating properties from cryogenic temperatures (around -200°C) up to about 100°C. Above this, they begin to soften, and significant thermal degradation occurs at higher temperatures. This stability makes them suitable for both refrigeration and standard building insulation.

- Moisture Resistance: Rigid, closed-cell polyurethane foam is highly moisture-resistant. Its cells are sealed, preventing water from penetrating the foam matrix. This property is critical for maintaining its high R-value and preventing mold and mildew growth, making it ideal for roofing, foundation insulation, and marine buoyancy.

- Ease of Molding: In its liquid state during production, polyurethane flows easily and can fill intricate and complex molds with high fidelity. This enables the creation of detailed parts with complex geometries, such as automotive dashboards, architectural moldings, or custom-shaped packaging, with minimal post-processing.

What is the Density of Polyurethane Foam?

The density of polyurethane foam is one of its most critical and variable properties, directly influencing its performance, feel, and cost. Density is measured as mass per unit volume, typically expressed in pounds per cubic foot (pcf) or kilograms per cubic meter (kg/m³). The density of PU foam can be precisely controlled during manufacturing by adjusting the amount of blowing agent used in the chemical reaction. More blowing agent creates a larger foam volume from the same amount of polymer, resulting in lower density.

The density range for PU foam is extensive. At the low end, flexible foams used for furniture back cushions or packaging might have a density of 1.0 to 1.5 pcf. Standard mattress and sofa seat cushions typically fall in the 1.8 to 2.5 pcf range. Higher-quality, more durable flexible foams, such as those used in high-traffic commercial seating or premium mattresses, can have densities of 3.0 pcf or more.

For rigid foams, the density range is equally broad and is chosen based on the application’s structural and insulating requirements. Standard rigid foam insulation boards typically have a density of around 2.0 pcf. This provides an optimal balance of high R-value and sufficient compressive strength for most construction applications. For applications requiring greater strength, such as structural cores, spray-on roofing foam, or machined prototypes, densities can range from 3 pcf up to 20 pcf. At the highest end, ultra-high-density rigid foam, often sold as tooling board, can reach densities of 40-60 pcf and is strong enough to be machined like wood or even aluminum.

What is the Melting Point of Polyurethane Foam?

A common point of confusion about polyurethane foam concerns its melting point. Unlike thermoplastic materials such as polystyrene or polyethylene, which have a distinct melting point at which they transition from a solid to a liquid, PU foam does not melt. This is because polyurethane is a thermosetting polymer. During the curing process, its polymer chains cross-link, forming a permanent, three-dimensional network. This chemical structure is irreversible.

Instead of melting, polyurethane foam undergoes thermal degradation at sufficiently high temperatures. The temperature at which this degradation begins depends on the foam’s formulation. Generally, standard rigid PU foams start to lose their structural integrity at temperatures between 100°C and 120°C (212°F and 248°F). If the temperature continues to rise, the polymer will start to char and decompose, breaking down into its chemical constituents and releasing smoke and gases. This process typically becomes significant at temperatures above 200°C (392°F).

This lack of an actual melting point is a key property that defines its use in many applications. It ensures dimensional stability at elevated service temperatures where thermoplastics would soften and deform. However, it also means that PU foam cannot be easily remelted and recycled in the same way as thermoplastics can. Understanding its thermal degradation behavior is critical for its safe use in high-temperature environments and for assessing fire safety performance.

What is the Chemical Formula of Polyurethane Foam?

There is no single chemical formula for polyurethane foam, as “polyurethane” describes a large family of polymers rather than a single compound. The chemical formula is better represented as a repeating structural unit within a polymer chain. The defining feature of all polyurethanes is the presence of the urethane linkage, which has the chemical structure -R-NH-CO-O-R’-.

The general formula for the polymer can be expressed as a repeating chain of these urethane linkages. The “R” and “R'” groups in the formula represent the backbone structures derived from the specific isocyanate and polyol used in the reaction. Because there are many different types of isocyanates (like MDI and TDI) and an even wider variety of polyols (polyether polyols, polyester polyols), the exact chemical makeup and resulting formula of the polymer chain can vary dramatically.

For example, a simple polyurethane could be formed from the reaction of a diisocyanate and a diol. The resulting molecular structure would be a long linear chain of alternating isocyanate and polyol residues connected by urethane groups. This structure is what gives PU foam its durability and flexibility. The cross-linking that occurs in rigid foams introduces a more complex, three-dimensional network structure. This intricate chemical composition is precisely what makes polyurethane so versatile, enabling its properties—from flexibility and softness to rigidity and strength—to be tailored for thousands of applications.

What is the Structure of Polyurethane Foam?

The structure of polyurethane foam is best described at the macroscopic level as a cellular solid. It is a matrix of solid polymer filled with gas-filled pockets, or “cells.” This cellular structure is what gives foam its characteristic low density and excellent insulating properties. There are two primary types of cellular structures in PU foam: open-cell and closed-cell.

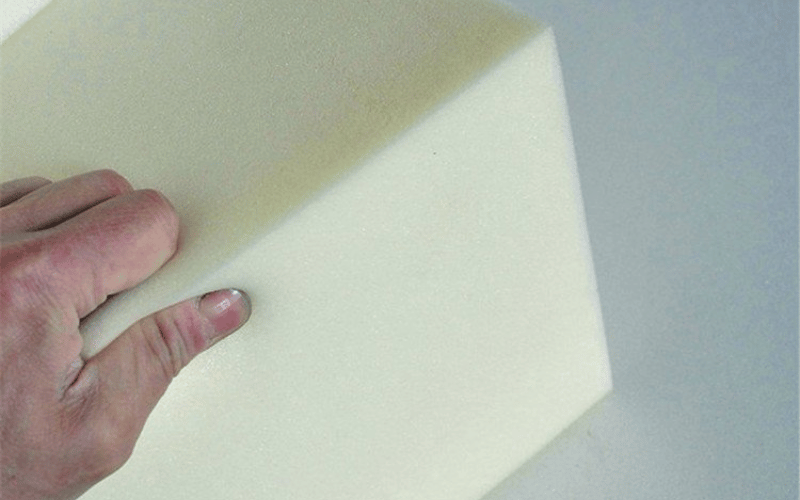

Open-Cell Structure: Flexible polyurethane foams typically have an open-cell structure. In this configuration, the individual cells are not entirely sealed off from one another; they are interconnected, forming a network of pathways through the foam. Think of it like a sponge. When you compress open-cell foam, air is pushed out of these interconnected cells. When the pressure is released, the foam springs back to its original shape, drawing air back in. This structure makes the foam soft, breathable, and excellent for cushioning applications such as furniture and mattresses. However, because air can move freely through it, open-cell foam is not a sound moisture barrier and has a lower insulation value than closed-cell foam.

Closed-Cell Structure: Rigid polyurethane foams are characterized by a closed-cell structure. In this case, each cell is a completely sealed, discrete pocket containing a trapped blowing agent (a gas). These cells are packed tightly together, but they do not connect. This structure provides several key benefits. First, the trapped gas is an inferior conductor of heat, which gives closed-cell foam its exceptionally high R-value and makes it an outstanding thermal insulator. Second, because the cells are sealed, the foam is highly resistant to water and moisture vapor, acting as a barrier. Finally, the rigid, sealed cell walls give the foam high compressive strength and structural stability. This combination of properties makes closed-cell foam ideal for insulation, structural panels, and flotation devices.

What is Polyurethane Foam Used For?

The applications of polyurethane foam are extensive, touching almost every primary industry due to its tunable properties. Its uses can be broadly categorized by whether the foam is flexible or rigid.

- Insulation: This is the primary application for rigid PU foam. Its high thermal resistance makes it the material of choice for insulating walls, roofs, and foundations in residential and commercial buildings. It is also essential in the refrigeration industry, used in refrigerators, freezers, and refrigerated transport trucks to maintain cold temperatures efficiently.

- Furniture and Bedding: Flexible PU foam is the cornerstone of the comfort industry. It is used as the cushioning material in virtually all upholstered furniture, including sofas, chairs, and office seating. In the bedding industry, it forms the support core and comfort layers in most mattresses and is the primary filling for pillows.

- –Automotive: The automotive industry uses both flexible and rigid PU foam extensively. Flexible foam is used for seat cushions, headrests, and armrests to provide comfort and support. Rigid foam is used in dashboards, door panels, and headliners for structural support and sound dampening. It is also used as an energy-absorbing material in bumpers and interior padding for passenger safety.

- Packaging: Flexible PU foam is used as a protective cushioning material for shipping fragile and high-value items. It can be cut into custom shapes to cradle products like electronics, medical equipment, and glassware, absorbing shocks and vibrations during transit.

- Construction: Beyond insulation panels, PU foam is used in construction as a spray-applied sealant to fill gaps and cracks, preventing air leakage. It is also a key component in Structural Insulated Panels (SIPs), where it acts as the core material sandwiched between two structural facings, creating a strong, energy-efficient building component.

Conclusion

Polyurethane foam is, without a doubt, one of the most versatile and impactful polymers in modern industry. Its ability to be engineered into a vast spectrum of forms—from soft, flexible cushioning to rigid, structural insulation—has made it an indispensable material in sectors ranging from furniture and automotive to construction and packaging. The core properties of PU foam, including its excellent thermal insulation, durability, and lightweight nature, provide solutions that enhance energy efficiency, comfort, and product longevity. Its cost-effectiveness and scalability have further cemented its role as a foundational material in global manufacturing.

However, the advantages of PU foam must be weighed against its significant environmental challenges. Its dependence on petrochemicals, its non-biodegradability, and the current limitations of its recycling infrastructure are critical issues the industry is actively working to address. The future of polyurethane likely lies in developing more sustainable practices, including the use of bio-based raw materials and advancing circular economy models through improved chemical recycling technologies. By acknowledging both its profound benefits and its current drawbacks, we can continue to innovate and use this remarkable material more responsibly and sustainably.