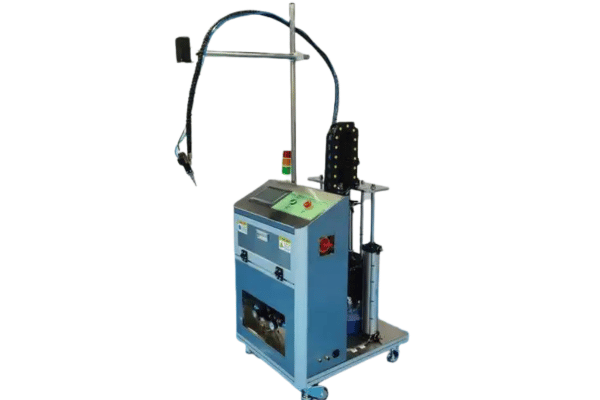

Polyurethane dispensing equipment is a cornerstone of modern industrial processes, enabling the precise application of PU materials across sectors like construction, automotive, and manufacturing. These systems are responsible for accurately mixing and dispensing the chemical components that form polyurethane foam, adhesives, and sealants. As industries push for greater efficiency and product quality, the demand for high-performance, reliable dispensing systems has never been higher.

Choosing the right equipment is not a simple task. With a vast array of options available, each with different technologies and capabilities, making an informed decision can be challenging. This guide simplifies the process by breaking down the features that truly matter, helping you select a system that delivers consistency, durability, and value.

From mixing technology and temperature control to automation and maintenance, we will explore the critical aspects of polyurethane dispensing equipment. This will help you understand what to look for when investing in a system for your business or production line.

Quick Check Guide for Polyurethane Dispensing Equipment

- Precision and Accuracy: Ensure the machine consistently maintains exact mixing ratios (e.g., 1:1). Look for advanced flow meters and pressure sensors that guarantee a homogenous mixture and prevent material waste.

- Durability: The equipment must be built to last in demanding industrial settings. Prioritize systems made of corrosion-resistant materials, such as stainless steel, and designed for continuous operation.

- Ease of Maintenance: Downtime is costly. Select equipment with self-cleaning functions, easily accessible components, and simple-to-replace parts to minimize maintenance time and ensure maximum uptime.

- Compatibility: The machine should be versatile enough to handle different polyurethane formulations, including various viscosities and blowing agents, without requiring extensive modifications.

As the industrial use of polyurethane grows, so does the need for equipment that can deliver flawless results. In applications ranging from automotive seating to building insulation, the final product’s quality is directly tied to the dispensing machine’s performance. A study in the Journal of Applied Polymer Science highlights that even minor deviations in mixing ratios can significantly degrade the mechanical properties of polyurethane foam. With technological advancements, modern equipment from brands like Henghui offers more than just dispensing; it provides process control and repeatability. However, the sheer number of choices can be overwhelming. This guide will help you focus on the features that make a real difference.

Consider the following features when deciding on the right polyurethane dispensing equipment for your industrial needs.

Key Features to Look for in Polyurethane Dispensing Equipment

Today’s industrial environments demand equipment that delivers not just performance but also intelligence and resilience. The most critical features center on precise mixing technology, robust temperature control to ensure material stability, and automation capabilities that integrate seamlessly into existing production lines. Prioritizing systems with adjustable flow rates and comprehensive safety features is essential to accommodate diverse applications while protecting operators.

Mixing Technology

The heart of any dispensing system is its mixing head. High-pressure systems impinge the two chemical components (isocyanate and polyol) at pressures up to 2,500 PSI, creating a highly turbulent flow that ensures thorough, rapid mixing without mechanical stirrers. This method is ideal for fast-reacting foams and high-volume production. In contrast, low-pressure systems use a mechanical mixer (agitator) to blend the components at lower pressures. They are often more suitable for slower-reacting materials or applications requiring more delicate handling.

Temperature Control

Polyurethane chemicals are highly sensitive to temperature. Maintaining an optimal temperature for both the A and B components is crucial for controlling reaction time and ensuring consistent foam density and quality. Look for equipment with integrated heating and cooling systems for the material tanks, hoses, and mixing head. Precise temperature control prevents crystallization and ensures the viscosity remains within the ideal range for perfect mixing and dispensing.

Flow Rate

The ability to adjust the flow rate is vital for versatility. Different applications require different volumes of material to be dispensed over varying timeframes. A machine with a wide range of adjustable flow rates allows a single unit to be used for multiple tasks, from filling large molds for automotive seats to applying small beads for sealing electronics. High-end machines offer precise, programmable control over the output volume.

Automation

For modern manufacturing, automation is key to efficiency. Look for equipment that can be integrated with robotic arms or automated production lines. Programmable logic controllers (PLCs) with user-friendly interfaces allow operators to program complex dispensing patterns, set specific shot sizes, and monitor the process in real-time. This reduces labor costs, minimizes human error, and increases throughput.

Safety Features

Working with polyurethane chemicals requires strict safety protocols. Modern dispensing equipment should include built-in safety mechanisms. These include emergency stop buttons, pressure relief valves to prevent over-pressurization, and automatic shutdown systems that trigger if a fault is detected. Fume extraction hoods and sealed systems also help protect operators from chemical exposure.

Durability and Weather Resistance

Polyurethane dispensing equipment often operates in harsh industrial environments, where it is exposed to dust, temperature fluctuations, and chemical spills. Therefore, robust construction is not a luxury but a necessity for ensuring long-term reliability and performance. When selecting a machine, it is critical to evaluate its durability and ability to withstand the specific conditions of your production facility.

High-quality materials are the foundation of a durable machine. Look for equipment made of corrosion-resistant materials, such as stainless steel, for all components that come into contact with chemicals. The frame and housing should be made from heavy-duty steel with a powder-coated finish to resist impact and environmental degradation. This ensures the machine maintains its structural integrity and performance over years of service.

Furthermore, the equipment must be designed to perform reliably under a range of operating conditions. Systems from reputable manufacturers like Henghui are engineered to function effectively in extreme temperatures and high-humidity environments. This often involves insulated tanks, heated hoses, and sealed electronic components that are protected from moisture and dust ingress. A machine designed for long-term durability with minimal upkeep will ultimately provide a better return on investment by reducing downtime and repair costs.

Precision and Accuracy in Dispensing

The quality of a polyurethane product is directly dependent on the precision of the dispensing equipment. Maintaining the exact mixing ratio of isocyanate and polyol is paramount; even slight deviations can lead to defects such as soft spots, brittleness, or improper curing. This makes precision and accuracy the most critical factors to consider when evaluating a machine.

Achieving this level of precision requires sophisticated technology. High-quality dispensing systems utilize advanced metering pumps—often magnetic-drive gear pumps or piston pumps—that deliver the chemical components with exceptional accuracy. These pumps are coupled with high-resolution flow meters that continuously monitor the output and provide real-time feedback to the control system. This closed-loop control allows the machine to automatically adjust for any variations, ensuring the mixing ratio remains perfect from the first shot to the last.

Regular calibration is also essential for maintaining long-term accuracy. Choose equipment that simplifies the calibration process and provides clear diagnostics. The inclusion of advanced sensors to monitor pressure, temperature, and flow not only ensures consistent output but also helps detect potential issues such as blockages or leaks early. For industries where quality is non-negotiable, investing in a machine known for its precision is a sound business decision.

Automation and Smart Features

In the era of Industry 4.0, automation and smart features are transforming manufacturing floors. Polyurethane dispensing equipment is no exception. Integrating smart technology enhances efficiency, reduces errors, and provides unprecedented control over the production process. For businesses looking to scale up and improve productivity, these features are indispensable.

Programmable settings are a key aspect of modern automation. Equipment with a sophisticated PLC and HMI (Human-Machine Interface) allows operators to create and save multiple dispensing programs. These “recipes” can preset parameters such as mixing ratios, shot sizes, flow rates, and dispense times for different products. This enables quick job changes with the touch of a button, ensuring consistency and minimizing setup time.

Furthermore, compatibility with smart factory systems is becoming increasingly important. Look for machines that can integrate with enterprise resource planning (ERP) systems and robotic automation. This allows for seamless communication across the production line. The ability to monitor and control equipment remotely is another valuable feature. It allows managers to track production data, diagnose issues, and even make adjustments from a central control room or a mobile device, maximizing operational visibility and efficiency.

Applications of Polyurethane Dispensing Equipment

The versatility of polyurethane means its dispensing equipment is used across a vast spectrum of industries. The ability to produce materials ranging from soft, flexible foams to hard, rigid plastics makes it an essential tool for innovation and manufacturing.

Construction

In the construction industry, polyurethane foam is a leading material for insulation and sealing. Dispensing equipment is used to spray foam insulation into walls, roofs, and attics, creating a seamless air barrier that significantly improves energy efficiency. It is also used for “slab jacking,” where foam is injected beneath sunken concrete slabs to lift and level them.

Automotive

The automotive sector is one of the largest users of polyurethane. Dispensing machines are critical for producing a wide range of components, including seat cushions, headrests, steering wheels, dashboards, and interior panels. The foam provides comfort, safety (through energy absorption), and sound dampening.

Packaging

For shipping fragile or high-value items, custom-molded polyurethane foam offers superior protection. Dispensing equipment is used in foam-in-place packaging systems, where a mixture is sprayed into a box lined with film. The foam expands around the object, creating a perfect, shock-absorbing cushion.

Industrial

Within industrial settings, PU dispensing equipment serves numerous functions. It is used for gasketing, where a precise bead of foam is applied to parts to create a waterproof or airtight seal. It is also used for void filling in machinery, structural reinforcement in composite panels, and for encapsulating sensitive electronic components to protect against moisture and vibration.

Maintenance and Troubleshooting

To ensure the longevity and consistent performance of polyurethane dispensing equipment, a proactive maintenance approach is essential. Regular upkeep not only prevents costly downtime but also guarantees the quality and safety of your production process. Neglecting maintenance can lead to blockages, inaccurate mixing, and equipment failure.

A routine maintenance schedule should be a priority. This includes daily cleaning of the mixing head to prevent cured material from causing blockages—a feature often automated in high-end machines. Regular inspection of hoses, seals, and filters is also crucial to identify wear and tear before it leads to leaks or system failures. Tanks should be kept clean and free of contaminants to protect the integrity of the chemical components.

Even with diligent maintenance, issues can arise. Common problems include material blockages in the mix head or lines, leaks from worn seals, and calibration errors affecting the mix ratio. Having access to comprehensive troubleshooting guides and technical support is invaluable. When selecting a supplier like Henghui, consider the availability of operator training and responsive technical support. This ensures your team is well-equipped to handle common issues swiftly, minimizing disruptions to production.

Cost and Warranty

While it can be tempting to choose the least expensive option, the initial investment in polyurethane dispensing equipment should be balanced with long-term value. A high-quality machine may have a higher upfront cost, but it often translates into significant savings through greater efficiency, reduced material waste, and lower maintenance requirements over its lifespan. Consider the total cost of ownership rather than just the purchase price.

A comprehensive warranty is a strong indicator of a manufacturer’s confidence in their product and provides crucial peace of mind. Look for a warranty that covers key components like pumps, motors, and control systems for at least one year. Understanding the terms, including what is covered and the process for making a claim, is important. A solid warranty protects your investment and ensures you have support if any issues arise. Ultimately, investing in reliable equipment with a good warranty from a trusted brand like Henghui is a strategic decision that supports long-term operational success.

Conclusion

Choosing the right polyurethane dispensing equipment requires a careful balance of features, durability, and cost to meet your specific production needs. From the precision of the mixing technology and the robustness of the temperature controls to the efficiency gains from automation, each aspect plays a vital role in your system’s overall effectiveness and reliability. Understanding these key features helps you make an informed decision that protects your investment and enhances your manufacturing capabilities.

The best equipment is one that not only fits your budget but also delivers the functionality, precision, and durability required to keep your operations running smoothly. By prioritizing quality and long-term value, you can ensure your business remains competitive and consistently produces high-quality products. Henghui has deep expertise in developing and manufacturing high-quality PU Foaming Machine solutions that empower industries to achieve their goals.

Remember, the right equipment is the foundation of a successful production line. Investing in a reliable, high-performance system from a trusted partner directly supports the long-term success and growth of your business. Take the time to research your options and choose a machine that will serve as a dependable asset for years to come.