Flexible polyurethane foam (FPF) is a ubiquitous and essential material that plays a silent but significant role in our daily lives. From the comfortable mattress you sleep on to the supportive car seat you commute in, and the protective packaging that safeguards your online deliveries, FPF is likely involved. Despite being hidden beneath fabrics or casings, its versatility and unique properties make it an indispensable component across a vast array of industries, including furniture, automotive, packaging, and healthcare.

However, despite its widespread presence, the specific composition and technical capabilities of flexible polyurethane foam remain a mystery to many. Understanding what FPF is, how it functions, and its diverse applications can empower manufacturers to select the best materials for their products and help consumers appreciate the engineering behind everyday comfort. Whether you are an industrial designer seeking the perfect cushioning solution or a homeowner curious about what’s inside your sofa, this article provides a deep dive into the world of flexible polyurethane foam.

Key Takeaways

- Flexible polyurethane foam is a polymer-based material known for its open-cell structure and resilience.

- It offers exceptional cushioning, breathability, and durability, making it ideal for comfort applications.

- The material is highly customizable in terms of density and firmness to suit specific industrial needs.

- FPF is widely used in furniture, automotive interiors, packaging, and medical devices.

- Advancements in technology are leading to more sustainable, bio-based foam options.

What Is Flexible Polyurethane Foam?

Flexible polyurethane foam (FPF) is a synthetic, resin-based material characterized by its lightweight nature and unique open-cell structure. It is chemically produced by the reaction of polyols and diisocyanates, forming the polyurethane polymer. Unlike rigid foams used for insulation, flexible polyurethane foam is designed to yield to pressure and spring back to its original shape, a property known as resilience. This fundamental characteristic is what makes it the premier choice for cushioning and padding applications worldwide.

The “open-cell” structure means that the air bubbles inside the foam are interconnected, allowing air to move freely through the material when it is compressed. This airflow is crucial for comfort, as it prevents heat and moisture buildup, unlike closed-cell foams, which seal air pockets individually. This structural difference is why FPF feels soft and breathable rather than stiff or rubbery.

Flexible polyurethane foam is categorized by its density and firmness, which can be chemically engineered to meet precise specifications. From the ultra-soft layers in a pillow-top mattress to the firm, supportive bolsters in a sports car seat, FPF adapts to the application’s requirements. It serves as the comfort layer in furniture, the impact absorber in packaging, and the sound-dampener in acoustic panels, showcasing an adaptability few other materials can match.

Key Characteristics of Flexible Polyurethane Foam

Flexible polyurethane foam is engineered to possess a specific set of physical properties that make it uniquely suited for comfort and protection. Here are the key characteristics that define FPF:

- Lightweight and Flexible: One of the most defining features of flexible polyurethane foam is its impressive weight-to-performance ratio. It is incredibly lightweight, helping reduce the overall weight of finished products such as automobiles or furniture without sacrificing volume or support. Its inherent flexibility allows it to be cut, shaped, and molded into complex contours, ensuring it can fit perfectly into the curved design of an ergonomic chair or the intricate shape of a custom packaging insert. This adaptability ensures that the material’s rigidity does not limit designers.

- Durability: Despite its soft and yielding nature, high-quality flexible polyurethane foam is exceptionally durable. It is designed to withstand repeated compression and release cycles—known as dynamic fatigue—without losing its height or support capabilities. This resistance to “bottoming out” or permanent deformation is vital for applications like mattresses and sofa cushions, which must support body weight for years. Advanced formulations also offer resistance to tearing and abrasion, ensuring the foam maintains its structural integrity over a long lifespan.

- Cushioning and Shock Absorption: The primary function of FPF in most applications is to provide cushioning and manage energy. The material excels at absorbing energy and distributing pressure evenly across its surface. In seating, this reduces pressure points on the body, enhancing comfort during extended periods of sitting. In packaging, this same property allows the foam to absorb shocks and vibrations during transit, protecting delicate electronics or glass from impact damage. Its ability to dampen energy makes it a superior choice for protective gear and safety equipment.

- Breathability: Unlike closed-cell foams or solid rubber, flexible polyurethane foam features a porous, open-cell structure. This allows air to circulate freely through the material every time it is compressed and released. This “pumping” action helps dissipate body heat and wick away moisture, creating a cooler and more comfortable microclimate for the user. In bedding and upholstery, this breathability is essential for preventing the accumulation of humidity, which contributes to a hygienic and pleasant sleeping or sitting environment.

The Manufacturing Process of Flexible Polyurethane Foam

The production of flexible polyurethane foam is a fascinating chemical engineering process that transforms liquid ingredients into a solid, cellular product. It begins with the precise metering and mixing of two primary components: polyols and diisocyanates. These are blended with water, catalysts, surfactants, and blowing agents in a mixing head. The reaction happens almost instantly; the mixture begins to bubble and rise—much like bread dough—as carbon dioxide gas is generated, creating the foam’s cellular structure.

This reacting mixture is typically poured onto a moving conveyor belt lined with paper or film in a process called “slabstock” production. As the foam travels down the line, it rises to its full height and begins to cure. The “bun” or long block of foam is then cut into manageable lengths and stored to cool and complete the curing process, which can take anywhere from 24 to 72 hours. Alternatively, the mixture can be injected directly into a mold to create specific shapes, a process known as molded foam production, commonly used for automotive seats.

Manufacturers can introduce various additives during the mixing stage to impart specific properties. Flame retardants are added to meet safety regulations for furniture and bedding. Antimicrobial agents can be included for medical-grade foams, while combustion modifiers help control density. Environmental considerations play a significant role in modern manufacturing; many producers now use “variable pressure foaming” (VPF) technology, which enables the creation of high-performance foams without the use of environmentally harmful auxiliary blowing agents, significantly reducing volatile organic compound (VOC) emissions.

The following video demonstrates the manufacturing process of flexible polyurethane foam.

Applications of Flexible Polyurethane Foam

Flexible polyurethane foam is a foundational material for modern living, providing the comfort and protection we rely on across numerous sectors. Its adaptability enables it to perform critical functions across diverse environments. Below are some of the most common applications of flexible polyurethane foam:

- Furniture and Bedding: This is FPF’s largest market. It serves as the core component in mattresses, sofa cushions, and upholstered chairs. In mattresses, different layers of FPF—ranging from high-density support cores to soft comfort layers—are stacked to provide the ideal balance of spinal alignment and pressure relief. In sofas and armchairs, it ensures that the seat retains its shape and comfort after years of daily use, preventing the sagging often associated with lower-quality fillers.

- Automotive Industry: The automotive sector relies heavily on molded flexible polyurethane foam for seating systems. It is used to create the complex, ergonomic shapes of car seats that provide lateral support and dampen road vibrations, reducing driver fatigue. Beyond seating, FPF is utilized in headliners, armrests, and headrests to enhance interior comfort. It also serves as a passive safety feature, used in knee bolsters and other impact-absorbing areas to protect occupants during a collision.

- Packaging: For shipping fragile or high-value items, flexible polyurethane foam is the gold standard for protective packaging. Its excellent shock-absorbing qualities allow it to cushion electronics, medical instruments, and glass against drops and impacts. The foam can be fabricated into custom inserts that hold products securely in place or used as “egg crate” convoluted foam to provide general protection. Its lightweight nature also helps keep shipping costs down compared to heavier packing materials.

- Medical Applications: In healthcare, patient comfort and safety are paramount. FPF is used extensively in hospital mattresses designed to prevent pressure ulcers (bedsores) by distributing weight evenly. It is also found in wheelchair cushions, providing essential stability and skin protection for long-term users. Additionally, specialized FPF acts as the padding in orthopedic braces and prosthetic limbs, ensuring a comfortable interface between the device and the patient’s body.

- Sports and Recreation: Gym mats, wrestling pads, and yoga props often utilize flexible polyurethane foam for its ability to cushion falls and provide a stable surface. In protective sports gear, such as helmets and shin guards, higher-density variants of FPF are used to absorb high-velocity impacts, protecting athletes from injury. It is also the core material in many soft play structures for children, ensuring a safe environment for active play.

- Acoustic Insulation: Due to its porous, open-cell structure, FPF is an effective sound absorber. It is widely used in recording studios as acoustic wedges to eliminate echoes and reverberation. In industrial settings, sheets of acoustic foam line generator enclosures and machinery housings to dampen noise pollution. Even in consumer electronics, small pieces of FPF are used inside speaker cabinets to improve sound quality by absorbing unwanted internal resonance.

Advantages of Flexible Polyurethane Foam

Flexible polyurethane foam offers a compelling suite of advantages that make it superior to traditional cushioning materials such as cotton batting, horsehair, and metal springs. Let’s explore the key benefits that keep FPF at the forefront of manufacturing:

- Versatility: FPF is incredibly versatile. It can be formulated to be as soft as a feather or as hard as a rock, and everything in between. This range allows it to serve as both a delicate packaging insert and a rugged automotive seat.

- Cost-Effectiveness: Compared to latex or specialized viscoelastic materials, standard flexible polyurethane foam is highly cost-effective to produce. Its raw materials are readily available, and the manufacturing process is efficient and scalable, making high-comfort products accessible at lower price points.

- Customizability: Manufacturers can tailor the chemical formulation to achieve precise performance metrics. Whether a client needs a specific density, hardness factor, or resilience level, FPF can be customized to meet those exact specifications, providing bespoke solutions for engineering challenges.

- Comfort and Support: The material provides a unique combination of comfort and support. Its ability to contour to the body eliminates pressure points, while its resilience ensures it pushes back enough to support weight. This ergonomic support is crucial for health and well-being in seating and sleeping applications.

- Sustainability: The industry is making strides in sustainability. Advances in production allow for the use of plant-based polyols and recycled content. Furthermore, scrap foam from the manufacturing process is almost entirely recyclable, often being re-bonded into carpet underlay, extending the material’s lifecycle and reducing landfill waste.

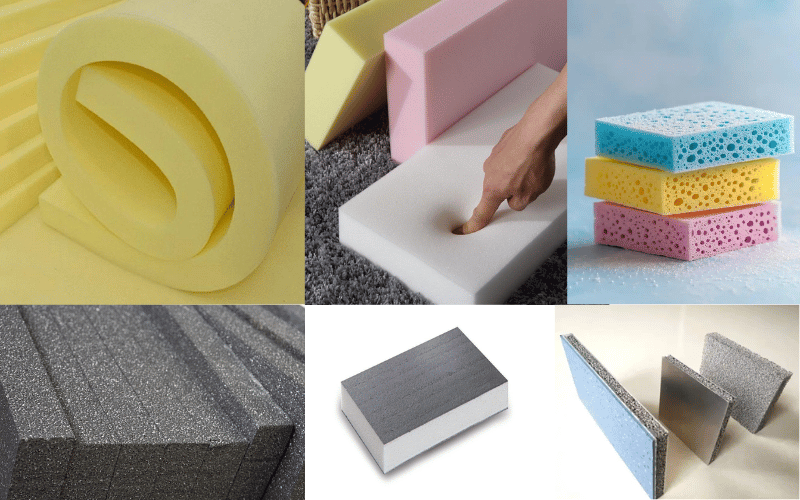

Types of Flexible Polyurethane Foam

While all flexible polyurethane foams share an everyday chemistry, they are manufactured in different grades to suit specific needs. Three main categories dominate the market, each with distinct properties and uses.

- High-Density Foam: High-density foam is the workhorse of the industry, prized for its longevity and support. In this context, “density” refers to the mass per unit volume, which directly correlates to durability. High-density FPF is used in high-traffic applications like commercial seating, premium mattresses, and automotive seats. It resists breaking down or softening over time, ensuring that the product feels as good in year five as it did on day one. It provides a firm, substantial feel that signifies quality in upholstered furniture.

- Memory Foam: Also known as viscoelastic polyurethane foam, NASA originally developed it. It is characterized by its slow recovery time and temperature sensitivity. When compressed, it molds perfectly to the body’s shape, creating a custom impression that relieves pressure points more effectively than standard foam. This makes it ideal for mattress toppers, orthopedic pillows, and medical cushions. The material softens in response to body heat, allowing for a “melting” sensation that cradles the sleeper.

- Reticulated Foam: Reticulated foam undergoes a post-production process that removes the thin cell membranes, leaving only the skeletal structure of the foam intact. This results in a highly open and porous material with high permeability. Reticulated foam is primarily used in air and water filtration systems, as fluids can pass through it easily while trapping particulates. It is also used in outdoor furniture cushions because it drains water instantly, preventing mold and mildew growth, and in acoustic applications where sound transparency is required.

Tips for Caring and Maintaining Flexible Polyurethane Foam Products

To ensure your flexible polyurethane foam products retain their comfort and shape for years, proper care is essential. The most critical rule is to avoid exposing bare foam to direct sunlight. UV rays act as a catalyst for oxidation, causing the foam to turn yellow and become brittle, eventually crumbling into dust. Always keep foam encased in a protective fabric or cover.

- In addition to UV protection, here are some practical maintenance tips:

Gentle Cleaning: If the foam itself needs cleaning, avoid harsh chemicals or soaking it thoroughly. Spot clean with a mild detergent mixed with water, blotting the stain gently. Do not wring or twist the foam, as wet foam is susceptible to tearing. Allow it to air dry completely in a shaded, well-ventilated area before putting the cover back on.

Rotate and Flip: For mattresses and sofa cushions, regular rotation is key. Flipping cushions or rotating a mattress head-to-toe every few months ensures even wear and prevents permanent body impressions from forming in one spot.

Proper Storage: If you need to store foam products, do not compress them for long periods. While foam is resilient, keeping it tightly compressed in a box or vacuum bag for months can weaken the cell structure, leading to permanent deformation. Store it flat in a cool, dry place to maintain its original dimensions.

Future Trends in Flexible Polyurethane Foam Technology

The flexible polyurethane foam industry is on the cusp of a green revolution, driven by consumer demand for sustainability and stricter environmental regulations. One significant trend is the shift toward bio-based polyols. Manufacturers are increasingly replacing a portion of the petroleum-based ingredients with oils derived from soy, castor beans, or sunflowers. These “bio-foams” reduce the carbon footprint of production and decrease reliance on fossil fuels without compromising the performance or comfort of the final product.

Additionally, circular economy initiatives are gaining traction. Technologies for chemical recycling—breaking down old foam back into its raw chemical components to create virgin-quality new foam—are advancing rapidly. This goes beyond simple mechanical recycling (such as carpet underlay) and promises a future in which a mattress can be endlessly recycled into new mattresses. We are also seeing the development of “smart foams” embedded with sensors for health monitoring in medical and automotive applications, pushing the boundaries of what this versatile material can do.

Conclusion

Flexible polyurethane foam is a triumph of modern material science, silently underpinning the comfort and functionality of our daily lives. From the essential support of a good night’s sleep to the safety of automotive interiors and the protection of shipped goods, its applications are as diverse as they are vital. Its unique combination of durability, breathability, and customizability makes it irreplaceable in industries ranging from healthcare to recreation.

As technology evolves, flexible polyurethane foam continues to improve, offering smarter, greener, and more efficient solutions for the challenges of tomorrow. Whether you are a business looking to innovate your product line or a consumer seeking the best value for your home, understanding FPF’s capabilities is the first step toward making informed choices. We encourage you to look more deeply into the foam specifications in your next purchase—because true quality often lies beneath the surface.