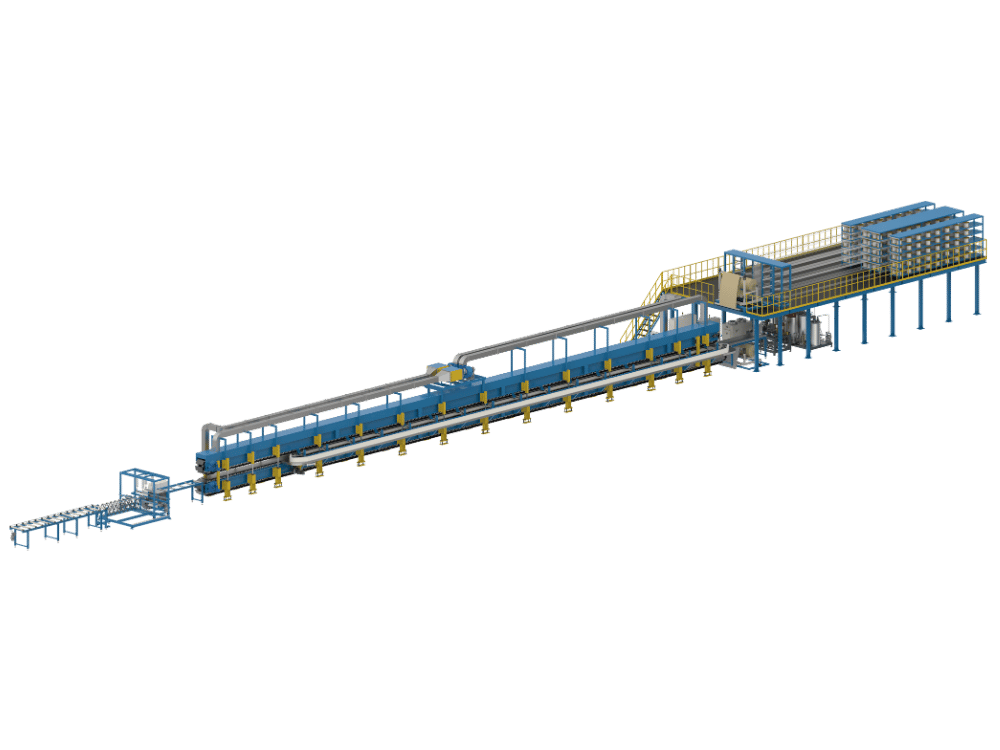

Large-Scale Composite Profile Extrusion Production Line

Provide You with Composite Profile Extrusion Line Solutions

Our Large Scale Composite Profile Extrusion Production Line combines accuracy and efficiency in the production of composite profiles made from glass fibre and polyurethane. Because of our experience, we serve the clientele of turboflex composite products and glass fibre reinforced composite products in modern, developed industrial applications.

China Polyurethane Equipment Manufacturer You Can Trust

Since 1999, Zhejiang Henghui Machinery Co., Ltd. has been at the forefront of polyurethane equipment manufacturing.

We are ISO 9001:2000 Certified. Annually, we manufacture and distribute more than 100 varieties of polyurethane equipment. With over 2500 systems in operation worldwide, we provide high-quality solutions and comprehensive services to ensure smooth production across a wide array of industries, including synthetic railway ties and high-strength composite panels.

Contact Us Now

Enter your inquiry details, We will reply you in 6 hours.

Large Scale Composite Profile Extrusion Production Line

This composite profile extrusion production line is designed to manufacture profile composites with glass fibre and polyurethane while maintaining high standards. The production line is precision-engineered to perform any extrusion application flexibly and efficiently, creating true composite and glass fibre engineered profile replicas.

Production Process

As a first step in production, glass fibre reinforcing materials, such as fibre bundles, cloth, and mats, are soaked in polyurethane. Then, using double-track presses, the materials are evenly distributed and compressed to achieve complete impregnation.

As the polymerisation reaction occurs in the composite, the material cures and takes the shape of the profile. The unit has a flexible, efficient profile that can be customised for specific requirements, with a pre-set length.

Key Features and Benefits:

Unlike traditional production lines, this advanced system integrates continuous operation with precision engineering, ensuring superior performance and efficiency. This design offers several benefits:

Continuous and Uniform Soaking

Ensures consistent quality and material distribution, resulting in defect-free composite profiles.

Double Track Compression

Provides even pressure during the production process, ensuring uniform impregnation and structural integrity.

Customizable Cutting Options

Profiles can be cut to pre-set lengths, offering flexibility to meet diverse application needs.

Durable and Reliable Design

Built for long-term use in demanding industrial environments, ensuring consistent performance over time.

High-Quality Results

Produces composite profiles with excellent structural integrity, durability, and performance.

Eco-Friendly and Cost-Effective Operation

The system minimizes material waste and energy consumption, reducing operational costs while supporting environmental sustainability.

Characteristics:

- Continuous and uniform soaking system

- Double-track compression for even material distribution

- Customizable cutting options for pre-set lengths

- High-precision polymerization and curing process

- Durable and reliable design for long-term industrial use

- Eco-friendly operation with minimal material waste

Application

- Railway Infrastructure: Synthetic railroad ties for durable and high-strength solutions.

- Construction & Insulation: High-strength composite panels for industrial and construction applications.

- Industrial Applications: Lightweight and robust composite profiles for demanding environments.

Why Choose This Production Line?

Our Composite Profile Extrusion Production Line is designed to be reliable, efficient, and precise. It is the ideal solution for industries requiring high-performance composite profiles, thanks to its advanced technology and customisability. Contact us now to discover how our production line can enhance your manufacturing capabilities and support your industry.