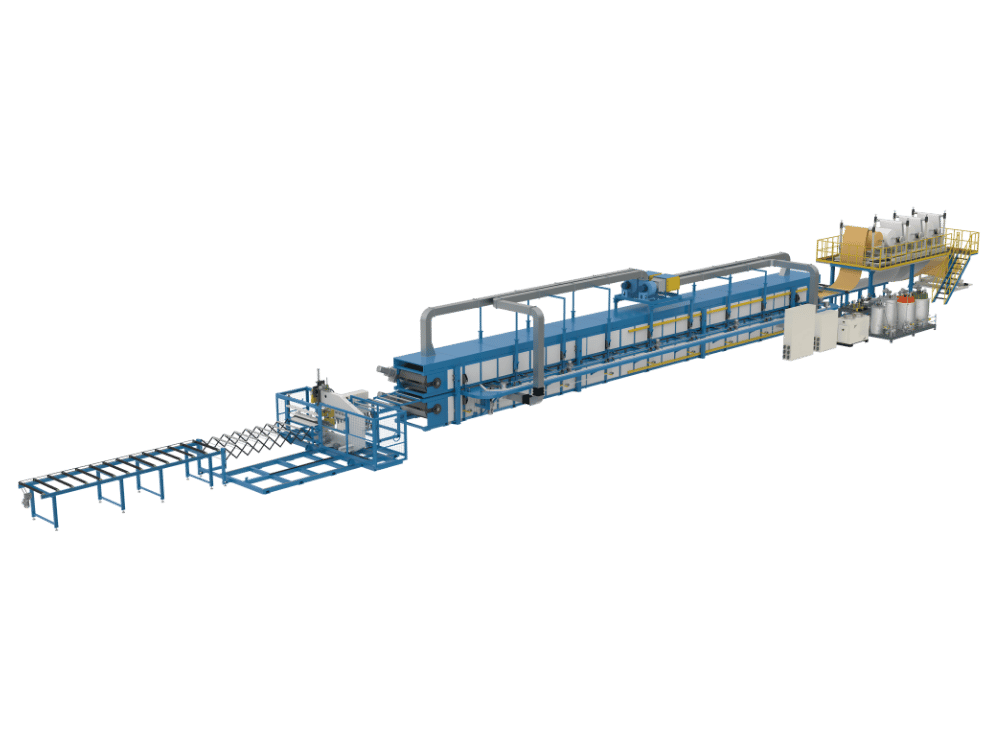

Continuous Glass Fiber Reinforced Polyurethane Foam Production Line

Offering Glass Fibre Reinforced Polyurethane Foam Production Line Solutions

Our Continuous Production Line of Glass Fibre Reinforced Polyurethane Foam operates efficiently and accurately, producing high-quality foam panels for various insulation applications. With over 20 years of experience, we deliver customised solutions for advanced insulation systems, ensuring consistent quality and reliability.

Reliable Polyurethane Equipment Manufacturer from China

Zhejiang Henghui Machinery Co., Ltd. began its journey in 1999. Over the years, it has become one of the foremost manufacturers of polyurethane equipment. Our production line delivers seamless injection, polymerisation, and moulding of the highest-quality fibreglass-reinforced polyurethane foam.

With more than 2,500 systems currently in operation worldwide, we are ISO 9001:2000 certified and offer dependable efficiency for LNG cargo enclosures, pipeline insulation, and other services.

Contact Us Now

Enter your inquiry details, We will reply you in 6 hours.

Advanced Glass Fibre Reinforced Polyurethane Foam Production Line

The production line is a Continuous Glass Fibre Reinforced Polyurethane Foam Production Line, demonstrating precision engineering, efficient production, and high-quality output of fibreglass composite foam. Polyurethane is injected continuously and uniformly into fibreglass mats, enabling the production line to meet the customer’s needs, who operates in fibreglass composite foam insulation and requires polyurethane and fibreglass composite foam insulation products of varying foam densities. The production line is the ideal candidate for the storage and transport of liquefied natural gas and the insulation of pipelines for cryogenic fluids, due to its reputation for consistency and reliability in the fibreglass mats industry.

How It Works

Production starts with continuous and uniform flows of the polyurethane reaction mixture and fibreglass mats into the mould. A double-track system compresses the fibreglass mats to ensure an even, complete mixture of glass fibre and polyurethane.

When the foam is manufactured and the polymerisation reaction is complete, the composite foam is moulded and eventually cut to the desired final form. The system consistently produces high-quality foam without air porosities at a consistent rate.

After being fully cured, the foam gets cut up. This cutting tool helps companies make foam boards for any project. It makes the foam boards flexible and super easy to make.

Key Features and Benefits:

Unlike traditional production lines, this advanced system integrates continuous operation with precision engineering, ensuring superior performance and efficiency. This design offers several benefits:

Continuous and Uniform Injection

Ensures consistent quality and material distribution, resulting in defect-free foam panels.

Customizable Cutting Options

Foam can be cut to pre-set lengths, offering flexibility to meet diverse production needs.

Durable and Reliable

Built for long-term use in demanding industrial environments, ensuring consistent performance over time.

Precision Engineering

Guarantees high-quality results with minimal material waste, optimizing production efficiency.

Double Track Compression

Provides even pressure during the production process, ensuring uniform impregnation and structural integrity of the foam.

Energy Efficiency

The system is designed to minimize energy consumption, reducing operational costs while maintaining high productivity.

Characteristics:

- Continuous and uniform injection system

- Double track compression for even material distribution

- Customizable cutting options for pre-set lengths

- High-precision polymerization and curing process

- Durable design for long-term industrial use

- Energy-efficient operation to reduce costs

Application

LNG Industry: Insulation layers for LNG liquid cargo enclosures and pipeline systems.

Construction & Insulation: High-performance foam panels for thermal and acoustic insulation.

Industrial Applications: Durable composite foam for demanding insulation projects.

Why Choose This Production Line?

Our Glass Fiber Reinforced Polyurethane Foam Production Line is engineered to meet the highest standards of precision, efficiency, and reliability. With its advanced technology and customizable features, it is the ideal solution for industries requiring high-quality insulation materials. Contact us today to learn how our production line can enhance your manufacturing capabilities and meet your insulation needs.