Versatile Resin Transfer Molding Machine: Supporting HP-RTM and C-RTM Processes

High-Pressure and Compression Resin Transfer Molding Solutions

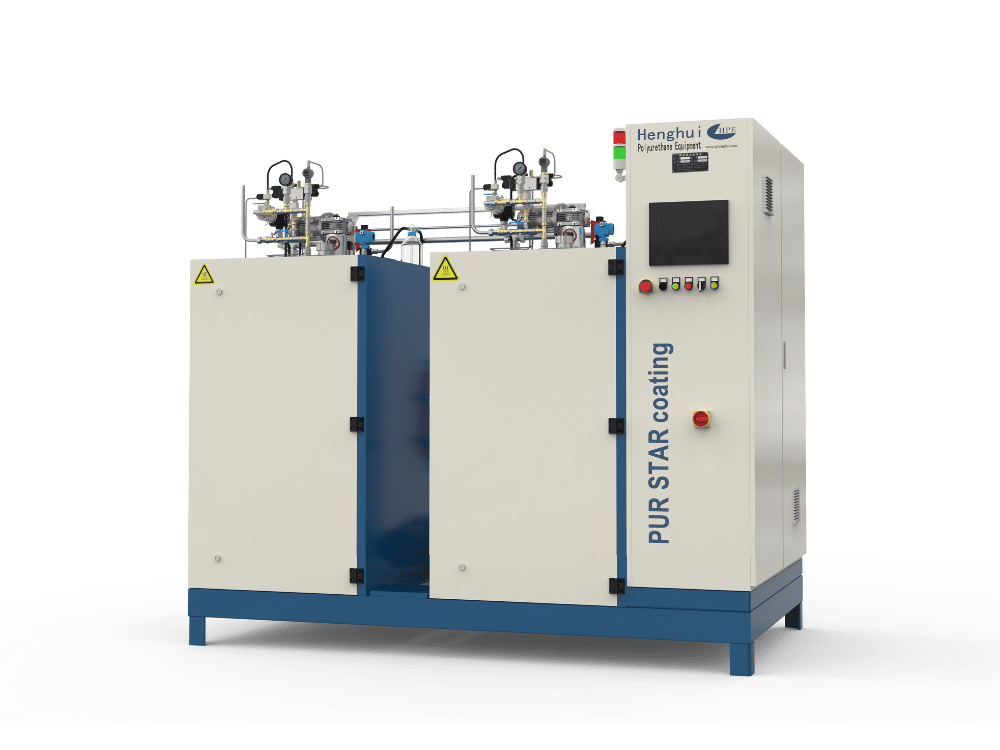

Our Resin Transfer Moulding Machine handles both HP-RTM (High-Pressure Resin Transfer Moulding) and C-RTM (Compression Resin Transfer Moulding), enabling you to fabricate lightweight, durable composite components efficiently and accurately. With more than 20 years of experience, we offer custom solutions for advanced moulding applications with proven repeatability and consistent quality.

Reliable Polyurethane Machines Manufacturer in China

Zhejiang Henghui Machinery Co., Ltd., established in 1999, is the leading company in the HP-RTM industry.

When certified to ISO 9001:2000, we design and produce 100 different models of polyurethane equipment each year. More than 2,500 of these systems are installed in over 45 countries worldwide. This demonstrates the reliability of the systems, with high-level services, strong systems, and seamless production.

Contact Us Now

Enter your inquiry details, We will reply you in 6 hours.

Supporting HP-RTM and C-RTM Processes

Techniques of Resin Transfer Molding Machine

Our advanced Resin Transfer Molding Machine is designed to support both HP-RTM (High Pressure Resin Transfer Molding) and C-RTM (Compression Resin Transfer Molding) processes. These cutting-edge technologies enable the production of lightweight, high-performance composite parts with superior surface quality and structural integrity.

Outflow(g/s)

1. HP-RTM Process.

HP-RTM processes begin with preforms of pre-shaped glass or carbon braid, or with adhesives to maintain orientation. A preform with a bonded structure is placed in a closed mould, and a vacuum is used to extract air bubbles. The vacuum ensures complete fibre impregnation. A low-viscosity polyurethane, epoxy resin, or cast nylon is injected into the mould cavity under high-pressure cycles, and the injected arm is then cured in a closed press to form additional high-performance, lightweight parts.

.png)

2. C-RTM Process.

The C-RTM process is somewhat different, as in this case, the resin is injected into a mould that is only partly closed. During the injection, the preform is partially filled with resin.

The mould is then closed, and the preform is fully compressed to ensure that all of the resin is contained within it and that all injected resin is utilised. This process allows for high precision and consistency in the end product.

Key Features and Benefits:

Unlike traditional resin transfer molding machines, this advanced system integrates high-pressure technology and automation to deliver superior performance and efficiency. This design offers several key advantages:

High-Pressure Technology

Ensures excellent mixing performance and fast response times.

Versatile Process Support

Compatible with both HP-RTM and C-RTM processes for flexible production needs.

Superior Surface Quality

Produces visible parts with high-quality finishes and scratch resistance.

Lightweight Components

Ideal for mass production of lightweight, high-performance composite parts.

Automation Ready

Fully automated for high-volume manufacturing.

Integrated Mold Release Agent

Mold release agents can be added directly to the mixing head.

Characteristics:

- High-pressure technology for fast-curing systems

- Excellent mixing performance and quick response times

- Supports both HP-RTM and C-RTM processes for flexible production

- Fully automated for high-volume manufacturing

- Mold release agent can be integrated into the mixing head

- Produces lightweight, high-performance composite parts with superior surface quality

Application

Automotive: Lightweight structural components, interior trim parts, and high-performance panels.

Aerospace: Carbon fiber-reinforced parts for lightweight and durable applications.

Consumer Goods: Thermoplastic parts with leather-like textures and high scratch resistance.

Industrial: High-strength composite parts for demanding environments.

What Makes Our Resin Transfer Moulding Machine Special?

What sets our Resin Transfer Moulding Machine apart is its ability to support both HP-RTM and C-RTM processes, creating top-quality, lightweight, high-performing parts with great surface finishes and structural integrity. The advanced processes are optimised for various industries and are cost-efficient and flexible. Get in touch with us today to find out how our Resin Transfer Moulding Machine can improve overall efficiency in your production process.