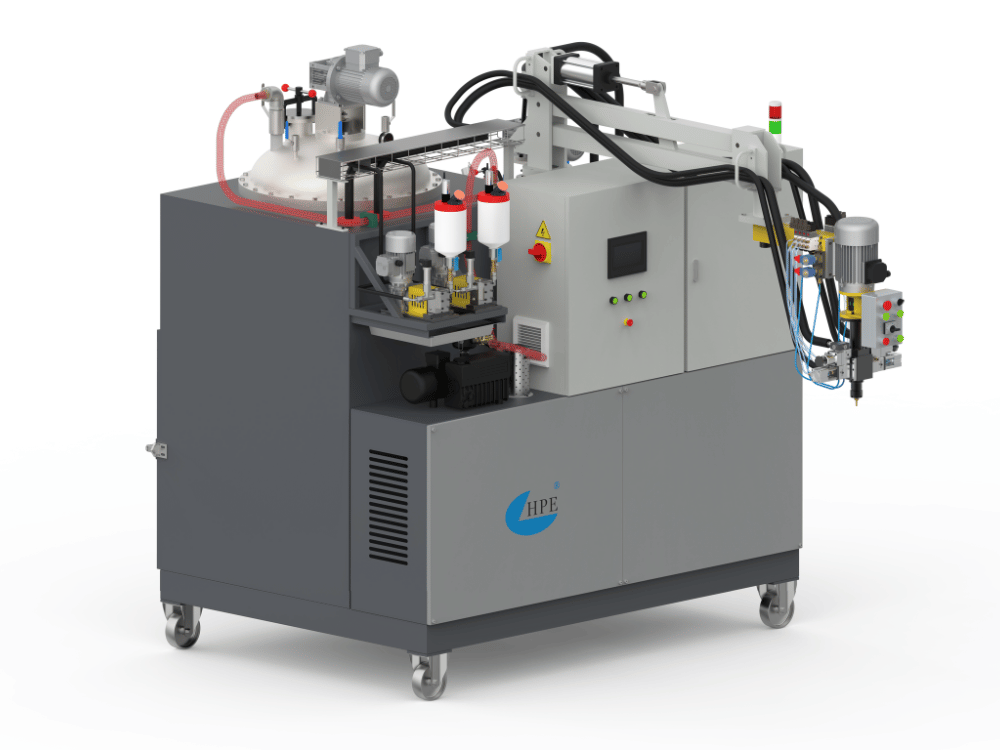

Two-Component Polyurethane Elastomer Casting Machine

Provide You with Polyurethane Elastomer Casting Solutions

Our QA Series Two-Component Polyurethane Elastomer Casting Machine ensures precision and efficiency, producing high-quality polyurethane elastomers through advanced chemical reactions and controlled processes. With over 20 years of expertise, we deliver tailored solutions to meet your elastomer production needs.

Trustworthy China Polyurethane Equipment Manufacturer

With a reputation built over the years, Zhejiang Henghui Machinery Co., Ltd. has specialized in producing polyurethane machinery from the very beginning. Established in 1999, Henghui has received ISO 9001:2000 certification for making over 100 types of polyurethane machinery each year, with more than 2500 units in operation worldwide. The company has obtained patents for several of its products, which are sold worldwide as of the highest quality. Their QA Series is an industry-standard product with great flexibility and is designed and manufactured for the highest quality.

Contact Us Now

Enter your inquiry details, We will reply you in 6 hours.

QA Series

Advanced Two-Component Polyurethane Elastomer Casting Machine

The QA Series Two-Component Polyurethane Elastomer Casting Machine is a high-performance system designed to produce polyurethane elastomers with precision and efficiency. Engineered for modern industrial needs, it ensures consistent quality and reliable operation in demanding environments. This machine is ideal for manufacturing two-component elastomer products, such as MDI + prepolymer or TDI + chain extender (e.g., MOCA).

How It Works:

QA Series machines pull stored raw materials from day tanks, which are then heated and vacuum-degassed. These materials are moved to a mixing head through electrically heated hoses. There, a turbine mixer is used to blend all components at high speed. The mixture is distributed to molds to form final elastomer products.

Operating at temperatures of 150 °C, this low-pressure dosing machine is built to withstand high-temperature chemical systems. Because of this ability, it is often termed a high-temperature machine.

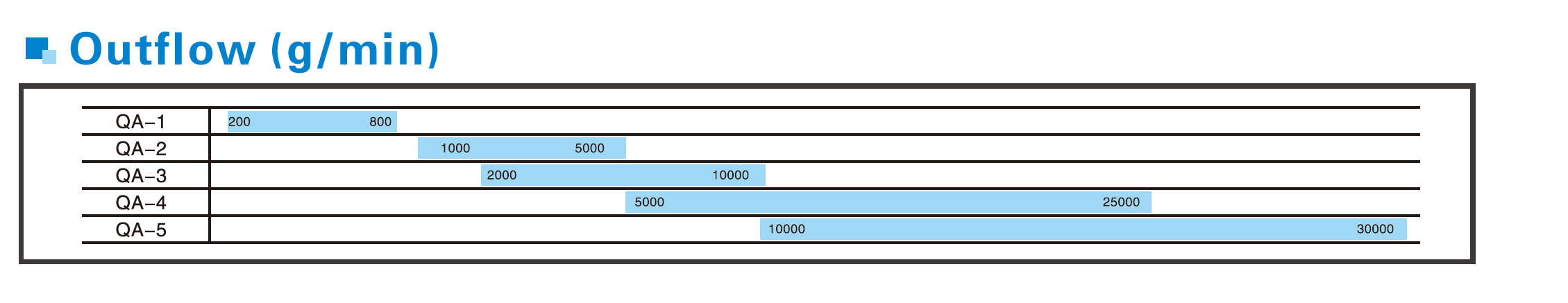

Outlet quantity form(g/s)

Key Features and Benefits:

Unlike traditional low-pressure machines, the QA Series employs a high-speed mixing turbine and an advanced material handling system, ensuring superior precision and efficiency. This design offers several benefits:

High-Temperature Capability

Operates at temperatures up to 150°C, making it suitable for demanding chemical systems and high-performance elastomer production.

Precision Mixing

The high-speed mixing turbine ensures uniform blending of components, resulting in consistent and high-quality elastomer products.

Efficient Material Handling

Gear metering pumps and electrically heated hoses maintain precise material flow, ensuring smooth and reliable operation.

Versatile Applications

Supports two-component systems such as MDI + prepolymer or TDI + chain extender (e.g., MOCA), making it adaptable to various production needs.

Reliable Performance

Engineered for consistent operation in industrial environments, ensuring durability and long-term reliability.

Eco-Friendly and Cost-Effective Operation

Minimizes material waste and reduces the need for cleaning agents, lowering operational costs and environmental impact.

Characteristics:

- Accurate measurement with a mixture ratio error of less than 0.3%.

- Innovative mixing device ensures good mixing and reliable performance.

- Various heating solutions (hot air heating, oil heating, oil-electrical combined heating) with a temperature error of less than ±2℃.

- Innovative outflow valve ensures excellent vacuum results, producing bubble-free products.

- Color pigment and additives can be directly added into the mixing head, increasing efficiency and reducing costs.

- Suitable for common casting, continuous casting, and rotary casting processes.

Application

- Elastomer Systems: TDI and MDI elastomer systems with MOCA, BDO, and other chain extenders.

- Automotive: Elastomer components for bushings, seals, and vibration dampers.

- Industrial Equipment: Rollers, wheels, and conveyor belts.

- Construction: Elastomer parts for structural components and insulation.

- Consumer Goods: Durable elastomer products for sports equipment, tools, and protective gear.

Why Choose the Two-Component PU Casting Machine?

The QA Series Polyurethane Elastomer Casting Machine stands out for its advanced features, precision engineering, and adaptability. It is the ideal choice for industries requiring high-quality elastomer products, offering superior performance, reliability, and efficiency.