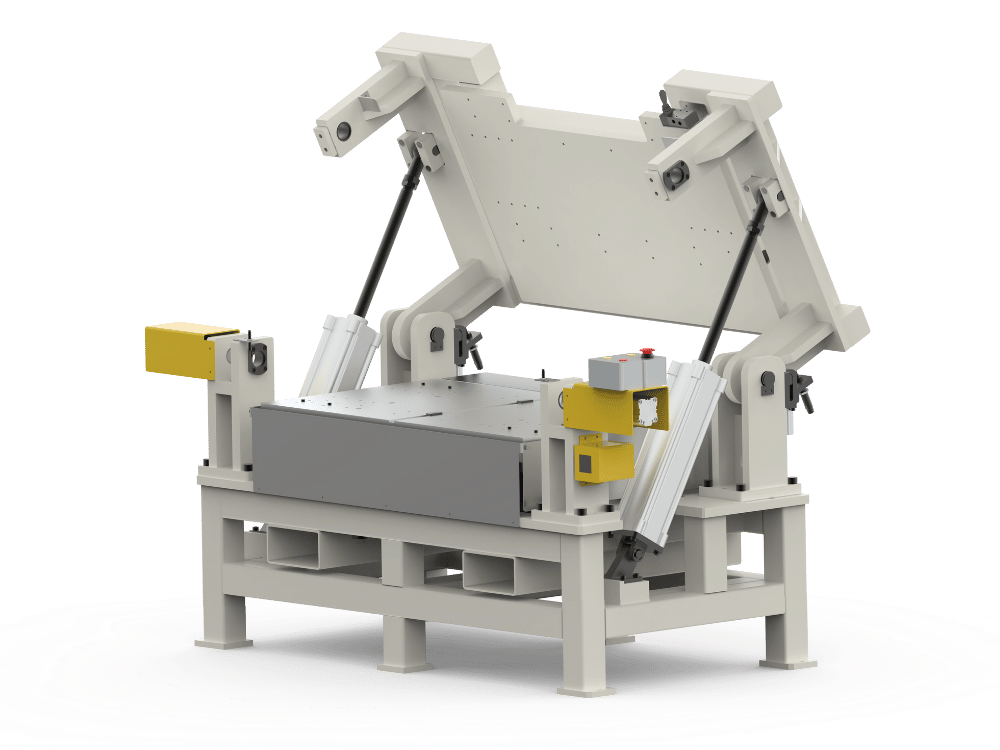

Polyurethane Foam Mold Carrier

Providing You with Polyurethane Foam Mold Carrier Solutions

With advanced driving methods, our Polyurethane Foam Mold Carrier delivers efficiency and precision in supporting foaming moulds. With over two decades of experience, we provide best-fit solutions to enhance diverse foaming processes and meet varying needs.

Reliable Polyurethane Foam Mold Carrier Supplier in China

Since 1999, Zhejiang Henghui Machinery Co., Ltd. has been one of the most prominent manufacturers of polyurethane equipment. Given the product’s process characteristics, our foam mould carriers are driven by electric, hydraulic, or pneumatic systems.

As an ISO 9001:2000 certified company, we manufacture and distribute over 100 polyurethane products each year. We are proud to have more than 2,500 systems operating worldwide in various domains, ensuring top-quality solutions.

Contact Us Now

Enter your inquiry details, We will reply you in 6 hours.

Enhanced Polyurethane Foam Mold Carrier For Peak Productivity

We designed our Polyurethane foam Mold Carrier to assist in the even, efficient foaming of moulds. Utilising state-of-the-art driving methods—electric, hydraulic, and/or pneumatic—this system delivers the highest foaming output, customised to address the unique process characteristics of different products.

The Mold Carrier is designed to hold foaming moulds in place during production securely. Based on the product specifics, the system is equipped with electric, hydraulic, or pneumatic drive methods for opening and closing. These technologies provide the system with enhanced lifting control, effortless movement, and uniform foam foaming to suit a wide variety of needs.

Key Features and Benefits:

Versatile Drive Methods

Supports electric, hydraulic, and pneumatic drives to meet diverse production needs.

Optimal Foaming Performance

Ensures consistent, high-quality results across various product processes.

Durable and Reliable Design

Built for long-term use in demanding industrial environments.

Precision Engineering

Guarantees smooth operation and minimal downtime.

Customizable Solutions

Tailored to the specific requirements of different molds and production lines.

Eco-Friendly Operation

Reduces material waste and energy consumption, supporting sustainable production.

Characteristics:

- Supports foaming molds with precision and stability

- Versatile drive methods: electric, hydraulic, or pneumatic

- Ensures optimal foaming performance for diverse processes

- Durable and reliable design for long-term industrial use

- Customizable to meet specific production requirements

- Smooth and efficient operation with minimal downtime

Application

Automotive: Foam components for seating, dashboards, and armrests.

Construction & Insulation: Rigid foam panels and thermal insulation products.

Appliances: Insulation for refrigerators, freezers, and water heaters.

Furniture & Bedding: Foam for mattresses, cushions, and ergonomic chairs.

Industrial Applications: Molded foam products for specialized uses.

Why Choose This Mold Carrier?

Our Polyurethane Foam Mold Carrier stands out for its advanced features, reliability, and adaptability. Engineered to deliver exceptional results, it is the ideal choice for industries requiring precision and efficiency in foaming applications. Contact us today to learn how our mold carrier can enhance your production capabilities and meet your industrial needs.