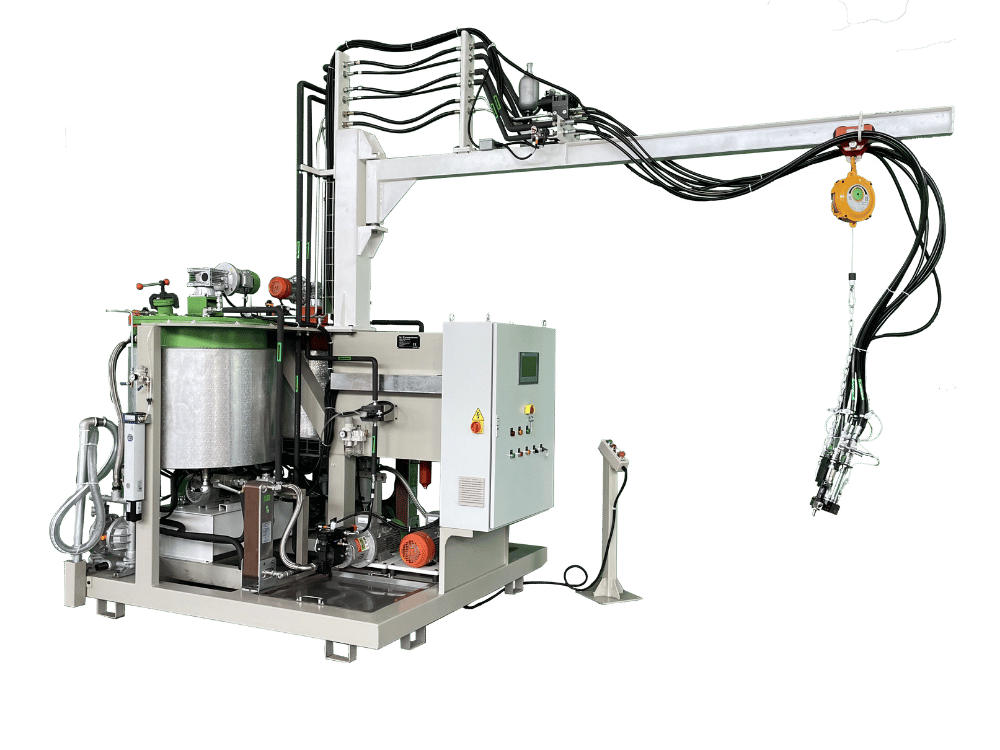

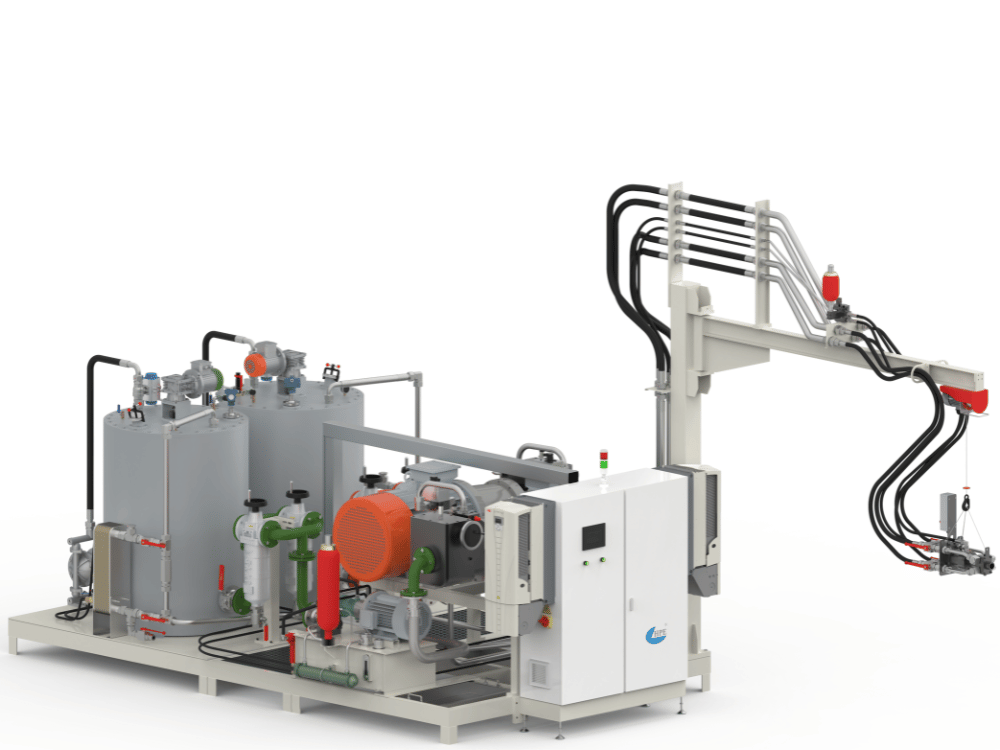

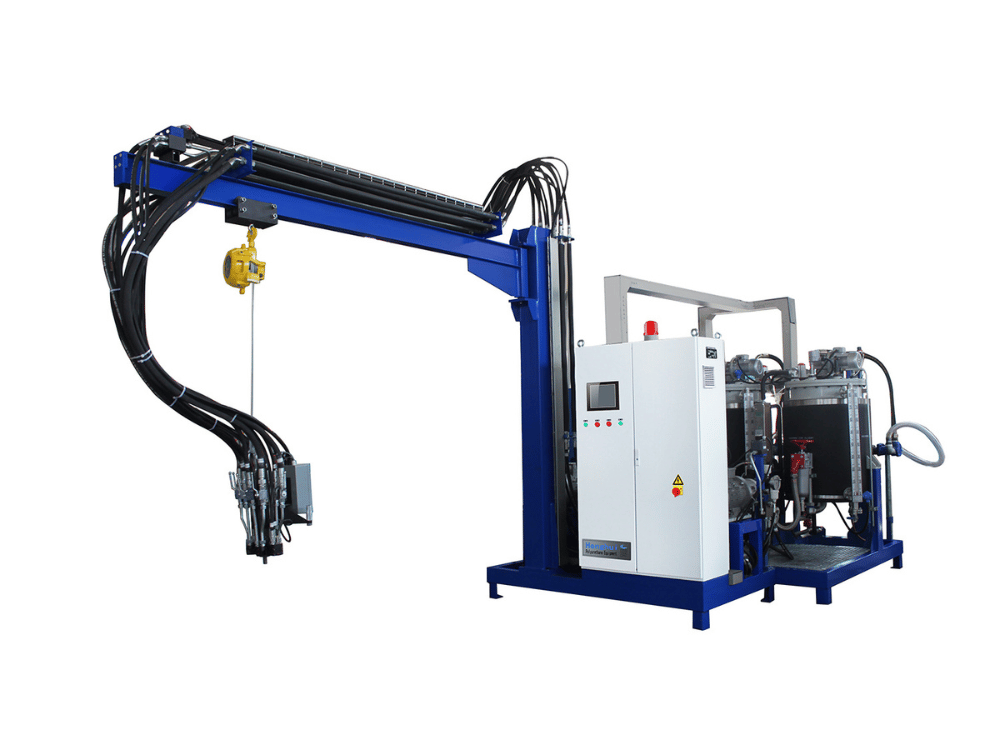

High-Pressure Polyurethane Foaming Machine

Provide You with Polyurethane High-Pressure Foaming Machine Solutions

Our High-Pressure Polyurethane Foaming Machine excels at delivering high-quality foam for a wide range of industrial foaming applications. Based on two decades of experience, we are best suited to provide low-to-medium and high-production, tailored solutions to ensure performance and cost efficiency.

Trustworthy China Polyurethane Equipment Manufacturer

In 1999, Zhejiang Henghui Machinery Co., Ltd. began manufacturing Polyurethane Equipment and is still considered one of the best in the Industry. High-Pressure Foam Making Machines, JHG20, JHG30, JHC, JHP, N Series, and PUR Hybrid Series. We Manufacture with Quality and Efficiency in Mind.

Our Machines Have Advanced, hydraulically driven self-cleaning mixing Heads that Reduce Materials and eliminate the need for Cleaning Agents. ISO 9001:2000 Certified, we Manufacture More than 100 different polyurethane systems per year, with More than 2500 Systems Installed Globally. We Provide Equipment for Different Sectors, Including Construction, Refrigeration, and Automotive Industries.

Contact Us Now

Enter your inquiry details, We will reply you in 6 hours.

Advanced High-Pressure Polyurethane Foaming Machine for Diverse Applications

Zhejiang Henghui Machinery Co., Ltd. supplies a range of high-pressure foaming machines across multiple industrial sectors. Ranging from two-component systems to specialised cyclopentane foaming machines and hybrid piston metering, we provide precision, efficiency, and green solutions.

More Info Guide: High-Pressure Polyurethane Foaming Machine

What is a High-Pressure Polyurethane Foaming Machine?

A high-pressure polyurethane foaming machine is specialized equipment that precisely mixes and dispenses two chemical components—polyol and isocyanate—to produce polyurethane foam. Unlike low-pressure models, this machine uses high pressure to atomize and impinge mix the materials. This process results in a superior and consistent foam product used in industries ranging from automotive and construction to furniture and refrigeration.

The machine's design centers on its high-pressure metering pumps and a self-cleaning mix head. The pumps deliver the two liquid components to the mix head at pressures often exceeding 1,500 PSI. Inside the head, the liquids collide at high velocity, instantly and thoroughly mixing without the need for a mechanical agitator. This impingement mixing ensures a homogenous chemical reaction and uniform cell structure in the final foam.

This high-pressure method offers significant advantages over low-pressure systems. The rapid and efficient mixing leads to better material yield and reduced waste. It also allows for faster production cycles, boosting overall efficiency. The precision of the process ensures consistent foam density and quality, which is critical for applications requiring specific performance characteristics. Furthermore, the self-cleaning nature of the mix head eliminates the need for solvent flushing between shots, making it a more environmentally friendly and cost-effective solution.

The Significance of High-Pressure Polyurethane Foaming Machines in Manufacturing

In modern manufacturing, high-pressure polyurethane foaming machines are essential for creating a wide range of products, from insulation panels to automotive parts and furniture. Their role is to combine and process chemicals into polyurethane foam with specific properties. The high-pressure impingement mixing ensures that the components are thoroughly atomized and blended. This process results in a uniform foam structure with consistent density and performance, which is vital for high-quality finished goods.

One of the machine’s most common applications is the production of rigid foam for the construction industry. This foam is an excellent insulator, used in building panels and spray foam applications to improve energy efficiency. Another primary use is in creating flexible foam for furniture and automotive seating. The machine's precision allows manufacturers to control the foam’s softness and resilience, ensuring comfort and durability in the final products.

Understanding the Difference Between High-Pressure and Low-Pressure Foaming Machines

Compared to low-pressure foaming machines, high-pressure models offer several key advantages. They are known for their superior mixing capabilities, which is crucial for achieving a uniform foam structure and consistent product quality. Additionally, high-pressure machines reduce material waste and allow for faster production cycles, making them more efficient for large-scale manufacturing.

The primary difference between high-pressure and low-pressure foaming machines is in their design and operational principles. Low-pressure machines typically use mechanical agitators to blend the chemical components, which are then dispensed through a mix head. In contrast, high-pressure machines use powerful pumps to force the components to collide at high velocity, a process called impingement mixing. This method ensures a more thorough and instantaneous blend without mechanical stirrers. High-pressure systems also offer better control over the mixing ratio and temperature, enabling more precise processing of various polyurethane formulations.

Key Elements of a High-Pressure Polyurethane Foaming Machine

A high-pressure polyurethane foaming machine is a sophisticated system composed of several critical components that work together to produce high-quality foam. Understanding these key elements is essential to appreciating the machine's precision and efficiency.

1. Mixing Head

The mixing head is where the chemical reaction begins. It uses a method called high-pressure impingement, in which streams of polyol and isocyanate collide at high velocity. This forceful impact atomizes the liquids, ensuring an instantaneous and thorough mix without mechanical stirrers. The precision of this process is vital for creating a homogenous mixture, which directly results in consistent foam density and uniform cell structure in the final product.

2. Metering Pumps

Metering pumps are the heart of the machine, responsible for delivering the polyol and isocyanate components to the mixing head. These high-pressure pumps are engineered for exceptional accuracy, ensuring the chemicals are supplied in the precise ratio required by the formulation. Their ability to maintain stable, high pressures (often over 1,500 PSI) is crucial for adequate impingement mixing and consistent output.

3. Heating System

The temperature of the chemical components significantly affects the foaming reaction and the final properties of the polyurethane. The heating system, which includes heating elements and temperature control systems for the material tanks and lines, maintains the polyol and isocyanate at their optimal temperatures. This precise thermal regulation ensures stable viscosity and predictable reactions, contributing to reliable, repeatable foam quality.

4. Control System

Modern high-pressure foaming machines feature advanced, automated control systems. These systems allow operators to manage the entire process with high precision and efficiency. Key features often include programmable settings for shot sizes, mix ratios, and component temperatures. Real-time monitoring provides immediate feedback on pressures and flow rates, enabling instant adjustments and ensuring that every part produced meets exact specifications.

5. Foam Dispensing System

Once mixed, the reactive liquid is dispensed from the mixing head into a mold or onto a surface. The foam dispensing system controls the flow and application of the material. Whether through a robotic arm for complex molds or a stationary head for continuous panel production, this system is designed to apply the foam uniformly, preventing voids or inconsistencies and ensuring the final product has the desired shape and density.

6. Cleaning System

To ensure consistent performance and prevent material buildup, the mixing head must be cleaned between dispensing cycles. High-pressure machines feature a self-cleaning mechanism. A hydraulic piston within the mix head purges any residual reactive material after each shot. This eliminates the need for chemical solvents to flush the system, reducing operational costs, minimizing downtime, and making the process more environmentally friendly.

How Does a High-Pressure Polyurethane Foaming Machine Work?

The operation of a high-pressure polyurethane foaming machine is a precise, multi-stage process that produces high-quality foam products. The machine's unique design ensures that the two chemical components, polyol and isocyanate, are perfectly mixed to trigger a specific reaction. Let’s explore how a high-pressure foaming machine works step by step.

1. Material Feeding

The process starts with feeding the raw materials—polyol and isocyanate—into separate, temperature-controlled tanks within the machine. From these tanks, the materials are drawn into high-precision metering pumps. This initial stage is crucial for ensuring a continuous and stable supply of chemicals is ready for the high-pressure mixing phase. The temperature control at this stage is vital for maintaining the correct viscosity of each component.

2. High-Pressure Mixing

Once fed from the tanks, the metering pumps propel the polyol and isocyanate at extremely high pressures (often over 1,500 PSI) into a small mixing chamber in the mix head. Here, the two chemical streams collide head-on in a process called impingement mixing. This high-velocity collision atomizes the liquids, creating an intensely turbulent environment that ensures an immediate and complete mixture. This step is the core of the high-pressure process, as it creates a homogeneous reactive liquid without any mechanical stirrers.

3. Foam Dispensing

Immediately after mixing, the now-reacting liquid is dispensed from the mix head. The dispensing system directs this liquid into a mold or onto a surface, depending on the final product being manufactured. The control system precisely manages the volume and flow rate of the dispensed material, a process known as the "shot." This controlled dispensing is critical to ensuring the mold is filled correctly and that the resulting foam has a uniform density, free of voids or defects.

4. Curing

Once dispensed, the chemical reaction continues, causing the liquid mixture to expand and solidify. This is the curing phase. The material expands to fill the mold cavity, forming its final shape and developing its internal cell structure. The time it takes for the foam to become solid enough to be removed from the mold is known as the curing time. This final step is essential for achieving the foam's desired physical properties, such as hardness, flexibility, and density.

Advantages of High-Pressure Polyurethane Foaming Machines

High-pressure polyurethane foaming machines provide several distinct advantages over low-pressure alternatives, making them the preferred choice for many demanding manufacturing applications. Let's explore some of the key benefits these advanced systems offer.

- Superior Mixing and Foam Quality: The impingement mixing process generates highly turbulent flow, ensuring a comprehensive, homogeneous blend of chemical components. This results in a uniform cell structure and consistent foam quality.

- High Production Efficiency: The rapid mixing and dispensing cycle, combined with self-cleaning mix heads that eliminate the need for solvent flushing, significantly reduces downtime between shots. This allows for faster production rates and greater overall throughput.

- Reduced Material Waste: The efficiency of high-pressure mixing ensures that all chemical components fully react, resulting in a higher material yield. The system's precision minimizes off-ratio pours and reduces scrap.

- Versatility in Formulations: These machines can effectively process a wide range of polyurethane formulations, including rigid and flexible foams, elastomers, and integral skin foams, accommodating various viscosities and reaction profiles.

- Precise Control Over Properties: Advanced control systems enable accurate management of mix ratios, temperatures, and shot sizes. This precision enables manufacturers to consistently produce foam with specific densities, hardness levels, and other physical properties.

- Energy Efficiency and Reduced Environmental Impact: The self-cleaning mechanism eliminates the need for harmful flushing solvents, reducing VOC emissions and disposal costs. The efficient process also consumes less energy per part produced than less-optimized systems.

These advantages make high-pressure polyurethane foaming machines a highly effective and reliable solution for industries requiring consistent, high-quality foam products, including automotive, construction, furniture, and refrigeration.

Applications of High-Pressure Polyurethane Foaming Machines

High-pressure polyurethane foaming machines are versatile and indispensable tools used across numerous industries. Their ability to produce consistent, high-quality foam with specific properties makes them essential for manufacturing a wide array of products. Let's explore some of the key applications for these advanced machines.

Construction Industry

In construction, polyurethane foam is prized for its excellent insulation and structural properties. High-pressure machines are used to produce rigid foam insulation panels for walls, roofs, and floors, significantly improving a building's energy efficiency. They are also used for spray foam applications, creating a seamless air barrier that seals gaps and cracks. Additionally, these machines help create structural insulated panels (SIPs) and other lightweight, durable building components.

Automotive Industry

The automotive sector relies heavily on polyurethane foam for safety, comfort, and performance. High-pressure foaming machines manufacture car seats, headrests, and armrests, providing both cushioning and long-term durability. They are also used to produce dashboards, interior trim components, and soundproofing materials that reduce engine and road noise, enhancing the driving experience.

Furniture Industry

High-pressure machines are fundamental to the furniture industry for creating flexible foam. This foam is used for cushions in sofas and chairs, as well as for mattresses. The precise control offered by these machines allows manufacturers to produce foam with varying degrees of softness and support, tailoring products to meet specific comfort and quality standards.

Appliance Industry

The insulating power of polyurethane foam is critical for the appliance industry. High-pressure machines are used to inject foam insulation into the walls of refrigerators, freezers, and water heaters. This high-quality insulation is vital for maintaining internal temperatures, improving energy efficiency, and meeting strict energy consumption regulations.

Other Applications

The versatility of high-pressure foaming technology extends to many other sectors. In the packaging industry, it is used to create custom-fit protective foam packaging for fragile or high-value items. In footwear, it is used to manufacture midsoles and insoles for athletic shoes, providing cushioning and support. The technology also finds use in producing specialized medical devices, sports equipment, and marine flotation components.