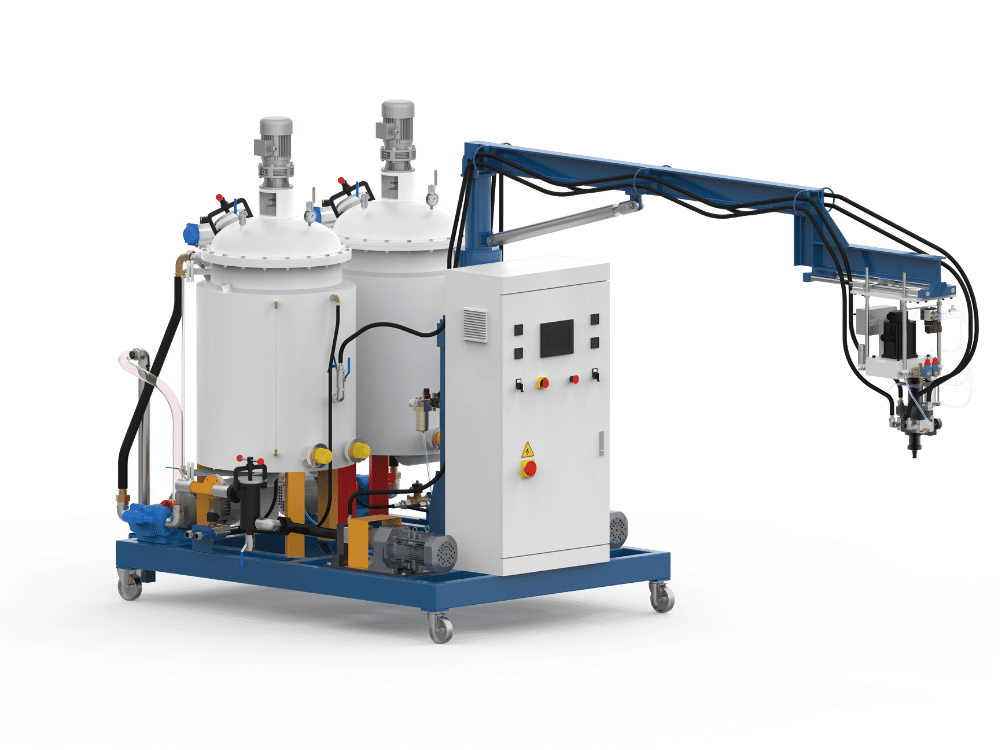

Low-Pressure Polyurethane Foaming Machine

Custom Solutions for Polyurethane Low Pressure Foaming Machines

Our Sturdy and reliable low-pressure polyurethane Foaming Machines provide accuracy, efficiency, and cost-effective quality foam for various markets and specialised industries. With more than 20 years of experience, we have customised small- and large-volume production machines for entry-level and start-up businesses, including foam contractors.

Polyurethane Equipment Manufacturer of Choice in China

Established in 1999, Zhejiang Henghui Machinery Co., Ltd. is an industry leader in the manufacture of polyurethane foam equipment. Our low-pressure foaming machines of the LA and LB Series have been crafted for operational excellence.

In the production of shoe soles, spray foaming, and edge bonding, the machines incorporate rotary turbine mixing heads and other specialised options for high operational efficiency. With thousands of machines designed and manufactured and an ISO 9001:2000 certification, we have systems in operation in construction, footwear, and automotive. Over 2500 of our systems are providing services globally. We have been in business for more than 20 years.

Contact Us Now

Enter your inquiry details, We will reply you in 6 hours.

Comprehensive Solutions for Low-Pressure Polyurethane Foaming Machine Applications

Zhejiang Henghui Machinery Co., Ltd. provides a range of low-pressure foaming machines for various applications. We offer two- and three-component systems, as well as tailored devices for the manufacture of shoe soles, spraying, and edge bonding, completing these tasks with a high level of detail and efficiency at a low cost.

More Info Guide: Low-Pressure Polyurethane Foaming Machine

What is a Low-Pressure Polyurethane Foaming Machine?

A low-pressure polyurethane foaming machine is a specialized piece of equipment designed to mix and dispense polyurethane components at low operating pressures. Unlike its high-pressure counterpart, this machine typically uses electric motors and pumps to deliver polyol and isocyanate liquids to a mixing head. This specific configuration offers distinct benefits, making it an excellent choice for specific manufacturing needs.

The machine's design enables precise metering and blending of the chemical components. As the liquids enter the mixing head, a mechanical stirrer, often rotating at high speeds, ensures they are thoroughly homogenized before being dispensed into a mold or onto a surface. This process is particularly advantageous for small-scale production runs or applications that require detailed, specialized pours.

The Significance of Low-Pressure Polyurethane Foaming Machines in Manufacturing

In manufacturing, the low-pressure polyurethane foaming machine is essential for creating a wide variety of foam products, from furniture cushions to automotive parts. The machine's mechanical mixing of components at low pressure is key to achieving the desired foam structure and density. This method allows precise control over the chemical reaction, resulting in a consistent, high-quality foam that can be used to produce goods such as insulation panels, decorative moldings, and more.

One of the most common applications of this technology is the production of flexible foam for seating and rigid foam for insulation. Low-pressure machines are designed to handle the specific requirements of these materials, providing reliable mixing and dispensing to ensure the final product meets exact specifications for comfort, durability, or thermal resistance.

Understanding the Difference Between Low-Pressure and High-Pressure Foaming Machines

Compared to high-pressure machines, low-pressure polyurethane foaming machines offer several key advantages. They are known for their lower initial cost and more straightforward operation, which are essential for businesses seeking a cost-effective entry into foam production. Additionally, low-pressure machines are often better suited for a broader range of polyurethane formulations, including those with higher viscosity or abrasive fillers, making them more versatile for specialized applications.

The difference between low-pressure and high-pressure foaming machines lies in their design and operational principles. Low-pressure systems use mechanical stirrers in the mixhead to blend components, while high-pressure systems rely on impingement mixing, in which streams of chemicals collide at high velocity. Low-pressure machines also offer easier cleanup and maintenance, enabling more flexible production for small batches or frequent material changes.

Key Elements of a Low-Pressure Polyurethane Foaming Machine

A low-pressure polyurethane foaming machine is a sophisticated assembly of several critical components, each playing a specific role in its efficient and reliable operation. One of the most vital elements is the mixing head, which comes in different designs to suit various applications.

1. Mixing Head

The mixing head is where the polyol and isocyanate components are blended. In a low-pressure system, this is achieved through mechanical stirring. A high-speed agitator within the head ensures the liquids are thoroughly combined, creating a homogeneous mixture before being dispensed. This mechanical action is crucial for achieving consistent foam quality and cell structure, especially in difficult-to-mix formulations.

2. Metering Pumps

The raw chemical components are delivered to the mixing head by metering pumps. These pumps ensure the precise ratio of polyol to isocyanate is maintained throughout the process. Operating at low pressures, these pumps, typically gear or piston types, provide a steady and accurate flow rate, which is essential for consistent foam properties and reaction.

3. Heating System

This system maintains the chemical components at their optimal processing temperatures. The tanks holding the polyol and isocyanate, as well as the hoses leading to the mixing head, are often heated. Proper temperature control is critical because it affects the viscosity of the liquids and the speed of the chemical reaction, directly impacting the final quality of the foam.

4. Control System

The control system is the brain of the machine, managing all operational parameters. These systems can range from simple manual controls to more advanced semi-automated PLC (Programmable Logic Controller) interfaces. They allow operators to set and monitor variables such as pump speeds, component ratios, temperatures, and shot timers, ensuring precision and repeatability in the production process.

5. Foam Dispensing System

This component is responsible for delivering the mixed polyurethane from the mixing head into the mold or onto a surface. It consists of the nozzle and any associated mechanisms that control the flow and pattern of the dispensed foam. A well-designed dispensing system ensures a smooth, even application, which is key to creating products with uniform density and finish.

6. Cleaning System

After a pour is completed, the mixing head must be cleaned to prevent the reactive chemicals from curing inside and causing a blockage. Low-pressure machines often use a solvent flush or a "purge" system that uses one of the components (typically the polyol) to clean the chamber. This can be a manual or semi-automatic process, vital for maintaining the equipment and ensuring readiness for the next production cycle.

By understanding the functions and interactions of these key elements, manufacturers can optimize the performance of the low-pressure foaming machine and achieve consistent, high-quality results for a diverse range of polyurethane applications.

How Does a Low-Pressure Polyurethane Foaming Machine Work?

The working principle of a low-pressure polyurethane foaming machine centers on its unique design for mechanically mixing chemical components. This configuration plays a crucial role in efficiently producing a wide range of polyurethane foam products. Let’s explore how the low-pressure machine works, step by step.

1. Material Feeding

The process starts by feeding the raw materials, liquid polyol and isocyanate, into separate temperature-controlled tanks. From these tanks, precision metering pumps draw the components and deliver them through hoses to the mixing head. This ensures a consistent and accurately proportioned flow of materials into the system.

2. Mechanical Mixing

As the two chemical streams enter the mixing head, a high-speed mechanical stirrer or agitator begins to rotate. This action vigorously blends the polyol and isocyanate at low pressure, generating a homogeneous mixture. The quality of this mixing is crucial for initiating a uniform chemical reaction and achieving the desired foam cell structure.

3. Foam Dispensing

Once thoroughly mixed, the reactive liquid is dispensed from the mixing head through a nozzle. The material can be poured into an open mold, injected into a closed cavity, or sprayed onto a surface. The control system precisely manages the shot size and duration to ensure the correct amount of material is dispensed for the specific application.

4. Curing

As the mixed polyurethane exits the dispensing nozzle, the chemical reaction continues, causing the liquid to expand and form a foam structure. The material then cures, hardening into its final, solid state. This curing process can occur at room temperature or be accelerated with heat. Proper curing is essential for the foam to develop its final physical properties, such as density, rigidity, and durability.

The low-pressure foaming machine’s unique design, with its mechanical mixing head and precise metering, makes it highly effective at producing consistent, high-quality foam. The ability to handle various formulations and the machine's simple operation contribute to its versatility in many industrial applications involving polyurethane foam.

Advantages of Low-Pressure Polyurethane Foaming Machines

Low-pressure polyurethane foaming machines offer several distinct advantages over their high-pressure counterparts, making them a preferred choice for various production applications. Let's explore some of the key benefits these machines provide.

- Cost-Effectiveness and Simplicity: Characterized by a lower initial investment and simpler mechanical design, which reduces maintenance requirements and operational complexity.

- Suitability for Small-Scale Production: Ideal for small batches, prototyping, or specialized runs due to easy setup, quick material changeovers, and lower cleaning solvent consumption.

- Versatility in Handling Formulations: Capable of processing a wide range of polyurethane systems, including those with high viscosity or abrasive fillers that can be challenging for high-pressure equipment.

- Precise Control Over Foam Properties: Mechanical mixing and adjustable pump speeds enable fine-tuning of component ratios and mixing intensity, directly influencing foam density and characteristics.

- Energy Efficiency: These machines typically consume less power compared to high-pressure systems, leading to lower operating costs and a reduced environmental footprint.

These advantages make low-pressure polyurethane foaming machines a versatile and efficient choice across industries such as furniture, automotive, insulation, and decorative molding.

Applications of Low-Pressure Polyurethane Foaming Machines

Low-pressure polyurethane foaming machines are versatile pieces of equipment that serve a wide array of industries, thanks to their ability to produce high-quality foam products efficiently. Let's explore some of the key applications of these machines.

1. Construction Industry

Low-pressure machines are vital in the construction sector, where they are used to produce rigid foam insulation panels and to apply spray foam. This foam provides excellent thermal and acoustic insulation for buildings, improving energy efficiency. The equipment's ability to handle different formulations makes it suitable for both on-site spray applications and factory production of insulation boards.

2. Automotive Industry

The precise control and flexibility of low-pressure foaming machines make them ideal for manufacturing automotive components. They are used to produce flexible foam for car seats and headrests, as well as semi-rigid foam for dashboards, door panels, and soundproofing materials. These applications enhance vehicle comfort, safety, and acoustic performance.

3. Furniture Industry

In the furniture industry, these machines are used to produce flexible foam products, such as cushions for sofas and chairs, as well as mattresses. The ability to control foam density allows manufacturers to produce items with varying levels of comfort and support. They are also used for making molded decorative components that mimic wood.

4. Appliance Industry

Low-pressure machines play a crucial role in the appliance industry by providing insulation for products like refrigerators, freezers, and water heaters. The rigid foam is injected into the cavities of these appliances, where it expands to form a seamless layer of insulation, critical to energy efficiency and performance.

5. Other Applications

The utility of low-pressure foaming machines extends to many other sectors. They are used to create protective foam packaging, soft, durable soles for footwear, and various components for medical devices, including positioning pads and housings for sensitive equipment.

With their versatility and efficiency, low-pressure polyurethane foaming machines remain indispensable in various manufacturing processes, driving innovation and enabling the production of high-quality foam products across diverse industries.