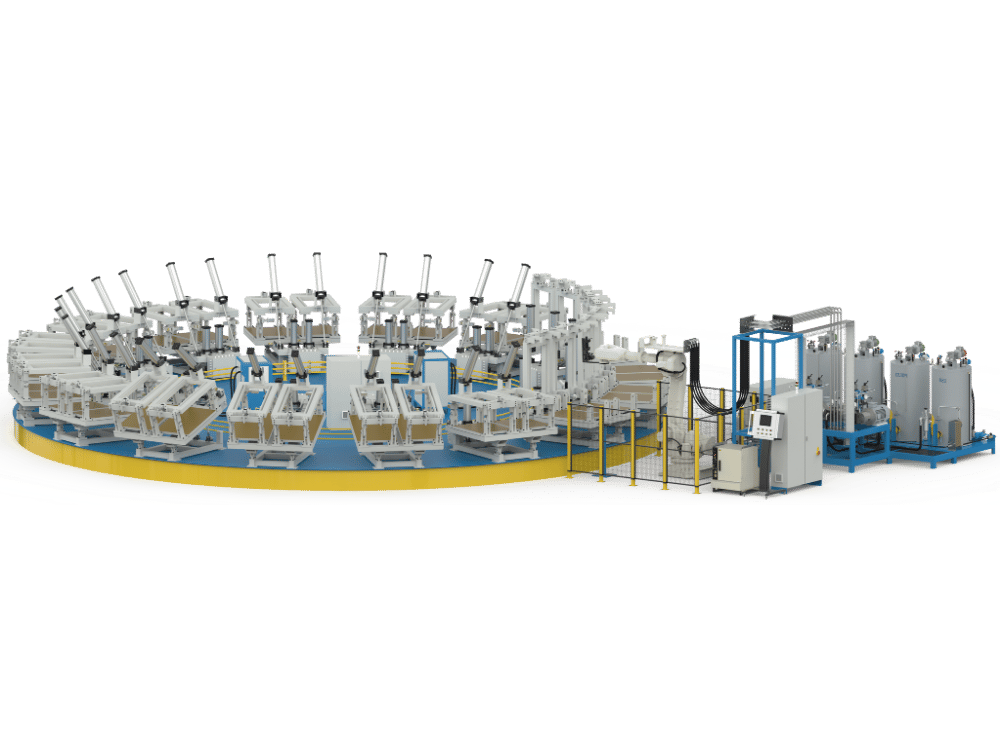

Polyurethane Mold Foaming Production Line | PU Foam Production Line

Advanced Solutions for PU Foam Production Lines

Our PU Foam Production Lines ensure precision, efficiency, and durability, meeting the diverse needs of small to large-scale batch production. With over 30 years of experience, we provide tailored solutions to optimize your polyurethane mold foaming processes.

Contact us today to learn how our PU Foam Production Line solutions can transform your manufacturing process.

Polyurethane Equipment Manufacturer You Can Rely On From China

Polyurethane Equipment Manufacturing Led Since 1999, Zhejiang Henghui Machinery, Co., Ltd. It is A Pioneer Service Provider. Our Equipment Are Designed For Differentiated Production Scales, And Provide Customers with Flexible Investments By Offering Disk Line, Semicircular Line, And Oval Line For Different Product Sizes.

Having Been Granted the ISO9001:2000 Certificate since 2003, We Are Now Presenting Over 100 Differentiated Models of Polyurethane Equipment, With More Than 2500 Units OEM-implemented in the Field. From Design To The Very End Of Support, We’ve Been Delivering Customised Solutions To Our Customers And To Industry Needs.

Contact Us Now

Enter your inquiry details, We will reply you in 6 hours.

Good Price And Quality PU Foam Production Line

Polyurethane foam is helpful in a variety of applications, including car seating and building insulation. Foam products made from Polyurethane must be manufactured using special machinery. Henghui Machinery is a manufacturer of all types and styles of Polyurethane Mold Foaming Production Lines. These machines automate foaming processes with great precision and efficiency at an economical rate, providing the best fit for every budget.

We focus on the thorough production of processing Polyol and isocyanate for the production of foam Polyurethane in a closed system. From temperature control to mixing ratios and injection time, every variable is controlled so that foaming remains part of a constant system. The quality and repeatability of the parts ensure our customers’ satisfaction and support retention. Suitable for any company and well-established enterprises.

PU Foam Production Line: From Basics to Applications

The PU foam production line is a versatile and essential system in the manufacturing industry, particularly in the production of polyurethane foam products. This advanced setup plays a pivotal role in transforming raw materials into a wide range of foam-based products, from furniture cushions to automotive components.

But what exactly is a PU foam production line? How does it operate? And what are its applications? In this section, we’ll explore the fundamentals of PU foam production lines, diving into their key components, operational principles, and the diverse industries that benefit from their capabilities.

What is a PU Foam Production Line?

A PU foam production line is a specialized system designed to manufacture polyurethane foam products efficiently and precisely. Unlike other production lines, it is specifically tailored to handle the unique chemical processes involved in creating PU foam, ensuring high-quality output for a variety of applications.

The production line typically consists of several key components, including mixing units, dispensing systems, conveyor belts, and curing stations. These elements work together seamlessly to mix raw materials, pour them into molds or onto surfaces, and cure the foam into its final form. This setup ensures precision and consistency throughout the production process.

What sets a PU foam production line apart is its ability to adapt to different foam formulations and product requirements. Its precision, efficiency, and versatility make it an indispensable tool for producing a wide range of foam products, from mattresses and insulation panels to automotive seating and packaging materials.

The Significance of PU Foam Production Lines in Manufacturing

In the manufacturing industry, PU foam production lines play a crucial role in creating high-quality polyurethane foam products. These systems are designed to ensure precision and consistency in foam density, shape, and overall quality, which are essential for meeting the diverse needs of various industries.

PU foam production lines are widely used in industries such as automotive, construction, furniture, and packaging. In the automotive sector, they are instrumental in producing seating, headrests, and insulation components. In construction, PU foam is used for insulation panels and sealants, while the furniture industry relies on it for cushions and mattresses. Additionally, the packaging industry benefits from PU foam's protective properties for delicate items.

The ability of PU foam production lines to deliver consistent and uniform foam products is what makes them indispensable. By maintaining precise control over the production process, these systems ensure that the final products meet stringent quality standards, making them a cornerstone of modern manufacturing.

Understanding the Difference Between PU Foam Production Lines and Other Production Systems

Compared to other foam production methods, PU foam production lines stand out for their efficiency, precision, and versatility. These systems are specifically designed to handle the unique chemical reactions and processes required to produce high-quality polyurethane foam, setting them apart from other production systems.

One key difference lies in the design and operation. While other foam production methods may rely on simpler setups, PU foam production lines incorporate advanced components like precision mixing units, automated dispensing systems, and controlled curing stations. This ensures consistent foam density, shape, and quality, which are critical for meeting diverse application requirements.

PU foam production lines also offer superior versatility, allowing manufacturers to produce a wide range of foam products, from flexible cushions to rigid insulation panels. Their ability to adapt to different formulations and product specifications makes them more efficient and reliable than traditional systems.

In summary, the advanced design, operational precision, and adaptability of PU foam production lines make them a superior choice for manufacturing high-quality foam products across various industries.

PU Foam Production Line Elements

The PU foam production line is composed of several key components, each playing a vital role in ensuring efficient and high-quality foam production. Here's a breakdown of these elements and their functions:

Mixing Unit

The mixing unit is responsible for blending raw materials such as polyol, isocyanate, and additives. Proper mixing is crucial to ensure a consistent chemical reaction, which directly impacts the quality and properties of the foam.

Foaming Unit

This unit controls the chemical reaction that creates the foam. By managing factors like reaction time and temperature, the foaming unit ensures the foam achieves the desired density, elasticity, and other properties.

Mold System

The mold system shapes the foam into specific forms or products. Whether producing cushions, insulation panels, or automotive components, the mold system ensures precision and uniformity in the final product.

Heating and Cooling Systems

These systems maintain the optimal temperature required for foam production. Proper temperature control is essential for ensuring consistent foam quality and preventing defects during the curing process.

Conveyor System

The conveyor system transports raw materials and finished products through the production line. It ensures a smooth and continuous workflow, improving overall efficiency.

Control Panel

The control panel monitors and adjusts production parameters such as temperature, pressure, and mixing ratios. This ensures precision and consistency throughout the production process, allowing for high-quality output.

By understanding the functions of these components, manufacturers can optimize the PU foam production line to produce a wide range of foam products with consistent quality and efficiency.

How Does a PU Foam Production Line Work?

The working principle of a PU foam production line is based on its advanced design, which ensures precision and efficiency in producing high-quality polyurethane foam products. Let’s break down the process step by step:

Material Feeding

The production process begins with the introduction of raw materials, including polyol, isocyanate, and various additives, into the system. These materials are fed through a hopper or automated feeding system, ensuring a consistent and controlled flow. Proper feeding is essential to maintain the correct ratio of chemicals, which directly impacts the quality of the foam.

Mixing and Blending

Once the raw materials are fed into the system, they are transferred to the mixing unit. Here, the chemicals are precisely blended to initiate the foaming reaction. The mixing unit ensures thorough homogenization, which is critical for achieving uniform foam properties. This step also prevents inconsistencies that could lead to defects in the final product.

Foaming and Expansion

After mixing, the chemical reaction begins, producing foam through the release of gas. This controlled reaction is carefully managed to ensure the foam expands to the desired density and elasticity. The foaming unit plays a crucial role in maintaining consistency, as even slight variations in the reaction can affect the foam's quality and performance.

Molding and Shaping

The foam is then poured into molds or shaped into specific forms using specialized equipment. This stage ensures that the foam takes on the desired shape and dimensions, whether for mattresses, insulation panels, or automotive components. The mold system is designed to provide precision and uniformity, ensuring that each product meets exact specifications.

Curing and Cooling

Once the foam is shaped, it undergoes a curing process to stabilize its structure. The curing stage allows the foam to solidify and achieve its final properties, such as strength, durability, and flexibility. Simultaneously, cooling systems are employed to regulate the temperature, preventing deformation and ensuring the foam retains its intended shape.

Cutting and Finishing

In the final stage, the foam products are cut, trimmed, or finished to meet specific requirements. Precision cutting equipment is used to achieve the desired dimensions, while additional finishing processes may include surface treatments or quality inspections. This step ensures that the foam products are ready for their intended applications, whether in construction, furniture, or packaging.

The PU foam production line’s step-by-step process, from material feeding to finishing, ensures the efficient and consistent production of high-quality foam products tailored to diverse industrial and consumer needs. Its advanced design and precise control over each stage make it a cornerstone of modern manufacturing.

Advantages of PU Foam Production Lines

PU foam production lines offer several distinct advantages, making them a preferred choice for manufacturing high-quality polyurethane foam products. Let’s explore the key benefits they provide:

Precision and Consistency

PU foam production lines are designed to ensure uniform foam quality across all products. Advanced mixing and dispensing systems maintain precise control over chemical ratios, resulting in consistent foam density, elasticity, and other properties. This precision is critical for meeting stringent quality standards in industries like automotive and construction.

High Efficiency

Optimized for large-scale production, PU foam production lines enable manufacturers to produce foam products at high output rates. Automated processes, such as material feeding, mixing, and curing, minimize downtime and maximize productivity, making these systems ideal for meeting high-demand requirements.

Versatility

One of the standout features of PU foam production lines is their ability to produce a wide range of foam products. From flexible cushions and mattresses to rigid insulation panels and automotive components, these systems can adapt to various formulations and product specifications, offering unmatched versatility.

Cost-Effectiveness

By reducing material waste and operational costs, PU foam production lines provide significant cost savings. Precise control over the production process minimizes errors and defects, while efficient use of raw materials ensures maximum yield, making these systems highly economical.

Customizability

PU foam production lines are highly adaptable to specific product requirements. Manufacturers can easily adjust parameters such as foam density, shape, and size to create customized products tailored to diverse applications, enhancing their market competitiveness.

Environmental Benefits

Modern PU foam production lines support sustainable practices by reducing material waste and energy consumption. Many systems are designed to minimize emissions and incorporate recycling capabilities, contributing to a more environmentally friendly manufacturing process.

These advantages make PU foam production lines an indispensable tool for manufacturers seeking precision, efficiency, and sustainability in producing high-quality foam products for various industries.

Applications of PU Foam Production Lines

PU foam production lines are highly versatile systems that cater to a wide range of industries, thanks to their ability to produce high-quality foam products with precision and efficiency. Let’s explore some of the key applications of PU foam production lines:

Automotive Industry

PU foam production lines play a vital role in the automotive sector, where they are used to manufacture car seats, headrests, and interior components. The foam's ability to provide comfort, durability, and lightweight properties makes it an ideal material for automotive applications. Additionally, PU foam is used for soundproofing and thermal insulation in vehicles.

Construction Industry

In the construction industry, PU foam production lines are employed to produce insulation panels, roofing materials, and sealants. The foam's excellent thermal insulation properties and resistance to moisture make it a preferred choice for energy-efficient buildings. PU foam is also used in structural applications, such as filling gaps and providing support in construction projects.

Furniture Industry

The furniture industry relies heavily on PU foam production lines for the creation of cushions, mattresses, and upholstery foam. The foam's flexibility, comfort, and durability make it an essential material for furniture manufacturing. PU foam is also used in ergonomic designs, providing support and enhancing user comfort.

Packaging Industry

In the packaging sector, PU foam production lines are used to produce protective foam for fragile goods. The foam's shock-absorbing properties and ability to conform to various shapes make it ideal for safeguarding delicate items during transportation and storage. PU foam is commonly used in custom packaging solutions for electronics, glassware, and other sensitive products.

Medical and Healthcare

PU foam production lines find applications in the medical and healthcare industries, where they are used to produce foam for medical devices, mattresses, and prosthetics. The foam's hypoallergenic properties, comfort, and adaptability make it suitable for use in hospital beds, wheelchair cushions, and orthopedic supports. PU foam is also used in wound care products and surgical pads.

With their ability to produce a diverse range of foam products, PU foam production lines are indispensable across multiple industries, driving innovation and enabling the creation of high-quality solutions tailored to specific needs.